Wood-grain-like inorganic artificial travertine and production process thereof

A technology of artificial travertine and imitation wood grain, applied in the direction of manufacturing tools, ceramic molding machines, and other household appliances, can solve the problems of low degree of automation, low production efficiency, and chaotic texture of imitation wood grain inorganic artificial travertine, and achieve Reduce material loss of water, reduce cracking, delay the effect of hydration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

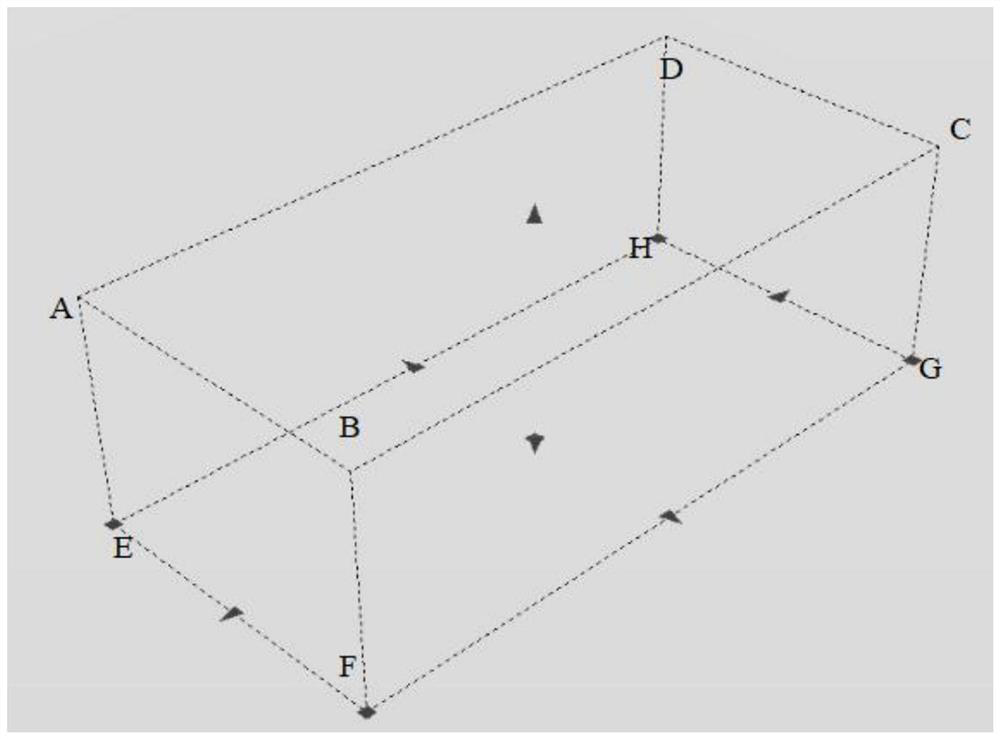

Image

Examples

Embodiment 1

[0058] An inorganic artificial travertine imitating wood grain, comprising the following raw materials in mass percentage: 26.74% of hydraulic gelling material, 0.46% of modification additive, 71.7% of filler, 1.0% of emulsion, and 0.1% of pigment;

[0059] The hydraulic cementitious material is Portland cement;

[0060] The modification auxiliary agent includes additive a, additive b, additive c, additive e;

[0061] The additive a is an aliphatic hydroxysulfonate polymer, and the addition amount is 1.2%wt of the amount of the hydraulic gelling material;

[0062] The additive b is starch grafted acrylate, and the addition amount is 0.1%wt of the amount of the hydraulic gelling material;

[0063] The additive c is aramid fiber, and the dosage is 0.3%wt of the hydraulic gelling material dosage;

[0064] The additive e is water glass, and the addition amount is 0.1%wt of the amount of the hydraulic gelling material;

[0065] Described filler is calcium carbonate powder, and t...

Embodiment 2

[0078] An inorganic artificial travertine imitating wood grain, comprising the following raw materials in mass percentage: 24.1% of hydraulic gelling material, 0.6% of modifying additive, 73.4% of filler, 1.6% of emulsion, and 0.3% of pigment;

[0079] The hydraulic cementitious material is composed of aluminate cement and gypsum in a mass ratio of 2:1;

[0080] The modification auxiliary agent includes additive a, additive b, additive c, additive d;

[0081] The additive a is a polycarboxylate polymer, and the addition amount is 1.9%wt of the amount of the hydraulic gelling material;

[0082] The additive b is an acrylamide-acrylate copolymerized cross-linked product, and the added amount is 0.1%wt of the amount of the hydraulic gelling material;

[0083] The additive c is polyvinyl chloride fiber, and the consumption is 0.4%wt of the hydraulic gelling material consumption;

[0084] The additive d is magnesium lignosulfonate, and the addition amount is 0.1%wt of the amount ...

Embodiment 3

[0098] An inorganic artificial travertine imitating wood grain, comprising the following raw materials in mass percentage: 27.8% of hydraulic gelling material, 0.5% of modification additive, 70.1% of filler, 1.2% of emulsion, and 0.4% of pigment;

[0099] The hydraulic cementitious material is Portland cement;

[0100] The modification auxiliary agent includes additive a, additive b, additive c, additive d;

[0101] The additive a is an aliphatic hydroxysulfonate polymer, and the addition amount is 1.2%wt of the amount of the hydraulic gelling material;

[0102] The additive b is starch grafted acrylate, and the addition amount is 0.1%wt of the amount of the hydraulic gelling material;

[0103] The additive c is polyvinyl chloride fiber, and the consumption is 0.3%wt of the hydraulic gelling material consumption;

[0104] The additive d is sodium citrate, and the addition amount is 0.1%wt of the amount of hydraulic gelling material;

[0105] The additive e is calcium alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com