Ultrafine hydrothermal barium titanate organic slurry and preparation method thereof, and ceramic diaphragm

A technology of ceramic diaphragm and barium titanate, which is applied in the field of materials, can solve problems such as cost waste and casting out, and achieve the effects of good compatibility, high uniformity, and simple and convenient preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In a second aspect, the present invention provides a method for preparing an ultrafine hydrothermal barium titanate organic slurry, comprising the steps of:

[0050] First disperse the ultra-fine hydrothermal barium titanate ceramic powder, trichlorethylene, absolute ethanol and fish oil in the formulated amount, and then mix with the formulated amount of polyether type defoamer, styrene glycol, octyl titanic acid The ester and vinyl binders were dispersed for the second time to prepare ultrafine hydrothermal barium titanate organic slurry.

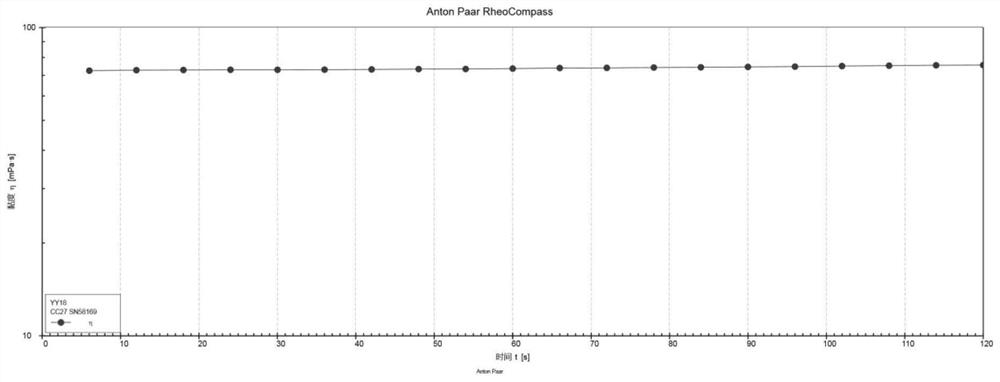

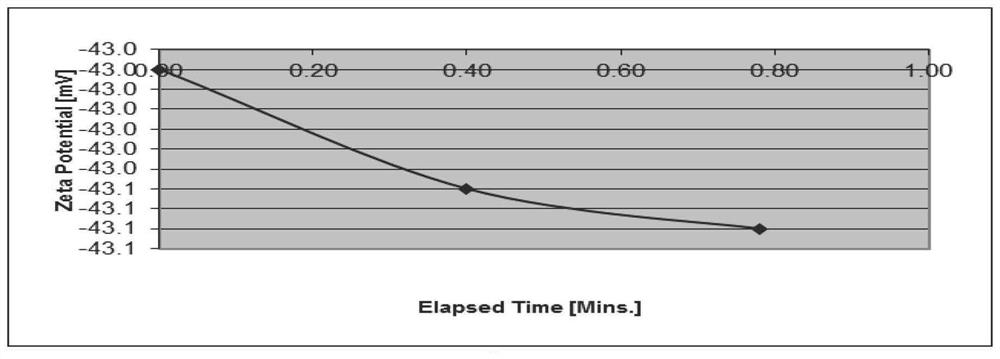

[0051] The preparation method of the ultrafine hydrothermal barium titanate organic slurry provided by the invention is simple and convenient, the prepared ultrafine hydrothermal barium titanate organic slurry is stable, and the ultrafine hydrothermal barium titanate is evenly dispersed.

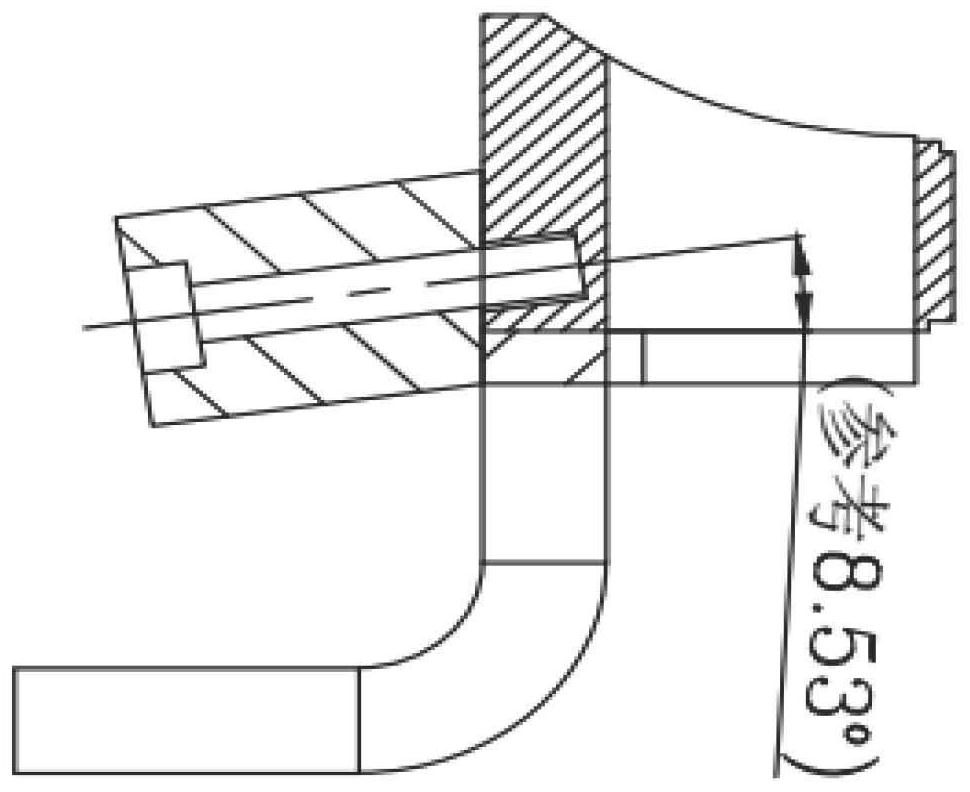

[0052] In some preferred embodiments, the first dispersion and the second dispersion are carried out in a sand mill. The present invention does...

Embodiment 1

[0066] An ultrafine hydrothermal barium titanate organic slurry, comprising 38.8 parts of ultrafine hydrothermal barium titanate (HBT-015), 33 parts of an organic solvent system (trichlorethylene: absolute ethanol = 52.0%: 48.0%), Herring fish oil 1.9 parts, phenylethylene glycol 0.12 parts, octyl titanate 0.18 parts, BH-11PVB glue 26.5 parts and polyether type defoamer 0.03 parts.

[0067] The preparation method is as follows:

[0068] Add the superfine hydrothermal barium titanate ceramic powder, trichlorethylene, absolute ethanol and fish oil into the cavity of the horizontal sand mill for dispersion. Put 0.65mm zirconium balls in the cavity in advance, and the zirconium balls The volume filling rate reaches 50%, the dispersion time is set to 8H, the pump speed is set to 340r / min, the spindle speed is 2300r / min on the upper half shaft, and 1200r / min on the lower half shaft.

[0069] Then add the polyether defoamer, styrene glycol, octyl titanate and BH-11PVB glue of the fo...

Embodiment 2- Embodiment 10

[0071]Embodiment 2-Example 10 all provide an ultrafine hydrothermal barium titanate organic slurry, and the distribution ratio of each component is shown in Table 1. The preparation method is the same as in Example 1.

[0072] Table 1

[0073]

[0074]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com