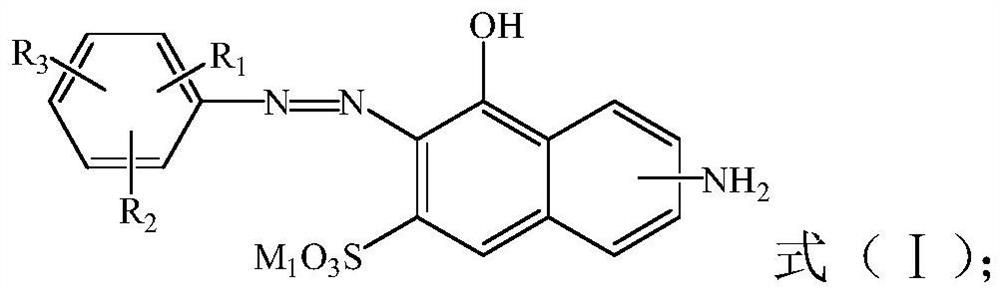

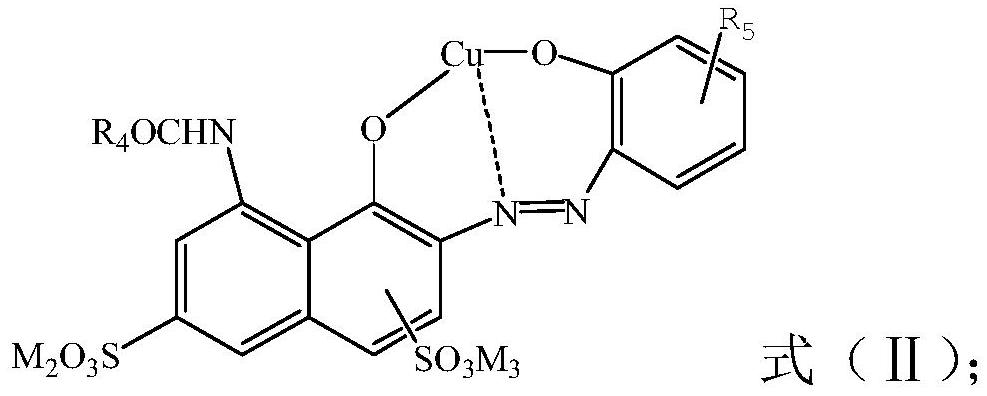

Reactive yellow dye composition, yellow dye and preparation method and application thereof

A dye composition, yellow dye technology, applied in dyeing methods, organic dyes, textiles and papermaking, etc., can solve the problems of poor dyeing fastness and dyeing performance, and achieve excellent dyeing fastness and dyeing performance, deep color , excellent lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

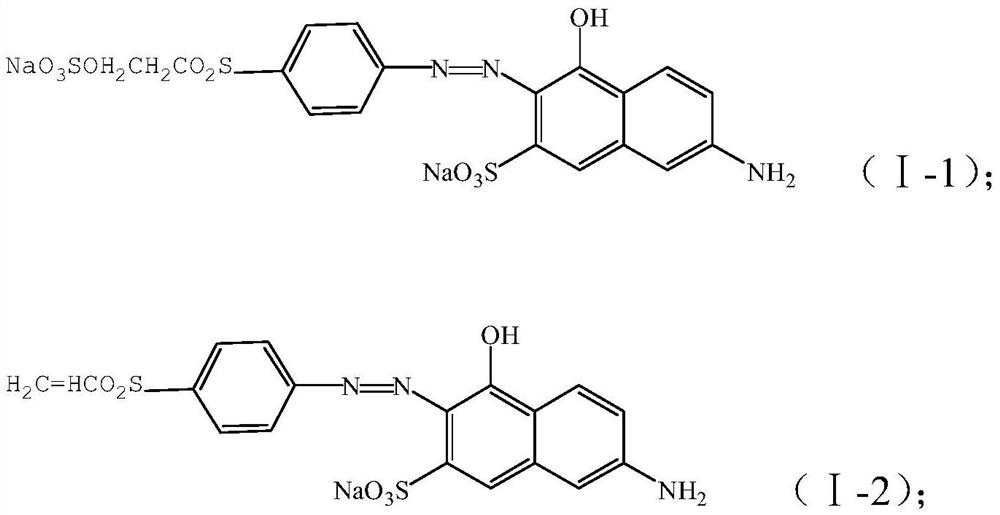

[0041] Formula (1) is prepared using the following synthetic methods

[0042] (1) Add 100-200 parts by mass of ice water to the glass, and then add 10-30 parts by mass of J acid and 5-20 parts by mass of maleic anhydride. Carry out once acylation reaction 2 ~ 5 hours, obtain formula (2) compound slurry, formula (2) molecular structural formula is:

[0043]

[0044] (2) Add 20-40 mass parts of formula (3) after adding 100-200 mass parts of ice water in the glass, add 7-10 mass parts of sodium nitrite, then add 50-70 mass parts of hydrochloric acid , carry out the diazo reaction for 2 to 3 hours at a temperature of 0 to 15°C to obtain the diazonium salt of formula (4), and the molecular structural formulas of formula (3) and formula (4) are:

[0045]

[0046] (3) Add the formula (2) to the synthesized diazonium salt formula (4), and carry out the coupling reaction for 3-7 hours under the conditions of an acid-binding agent, a temperature of 0-10° C., and a pH=6.5-8.5 to obt...

Embodiment 2

[0050] (1) Add 100-200 parts by mass of ice water to the glass, then add 10-30 parts by mass of J acid and 5-20 parts by mass of maleic anhydride, at a temperature of 1020°C and pH=3.06.5 The acylation reaction was carried out once for 25 hours to obtain compound slurry.

[0051] (2) After adding 100-200 mass parts of ice water in the glass, add 20-40 mass parts of para-ester, add 7-10 mass parts of sodium nitrite, then add 50-70 mass parts of hydrochloric acid, The diazonium reaction was carried out at a temperature of 0-15°C for 23 hours to obtain the para-ester diazonium salt for later use.

[0052] (3) Add J acid acylation to the synthesized para-ester diazonium salt, adjust pH=6.5-8.5 with acid-binding agent sodium bicarbonate, and carry out coupling reaction at 0-10°C for 3-7 hours, A coupling compound slurry was obtained.

[0053] (4) Add a basic compound to the coupling compound and raise the temperature to 60-80° C. and carry out hydrolysis reaction under the condit...

Embodiment 3

[0056] According to the data in Table 1, component A, component B, co-solvent and water are blended with liquid slurry, mixed evenly, and then spray-dried or powder blended. The blending time is 2 hours.

[0057] Table 1: The proportioning ratio of the dye raw material composition of Experiment No. 1-7 is as follows:

[0058]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap