Adsorption concentration runner blast furnace gas desulfurization system and method thereof

A technology of concentrating runner and desulfurization system, which is applied in the selection of absorbing solid gas purification, combustible gas purification, and removal of gas pollutants, etc., can solve the problem of reduced hydrolysis efficiency and life, increased equipment footprint, Catalyst damage and other problems, to achieve the effect of reducing equipment size, reducing investment, and simplifying the process of desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

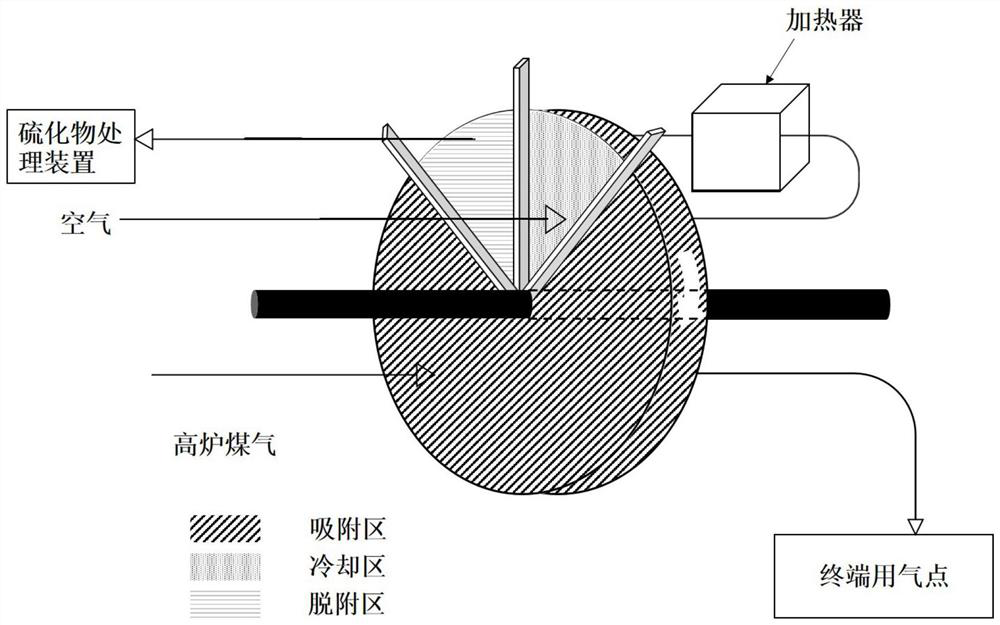

Embodiment 1

[0029] As shown in the figure, the enrichment rotor is filled with activated carbon adsorbent modified by alkali metal, blast furnace gas (containing CO 2 , CO, COS, H 2 , H 2 S, where COS stands for organic sulfur) is introduced into the concentrating runner and adsorbed in the adsorption zone. The clean gas after adsorption enters the pipe network to reach the gas consumption point. The concentrating runner rotates clockwise at a rate of 8r / min. Adsorption in the adsorption area is completed, and the rotor is transferred to the desorption area. The hot air blowing at 500°C in the desorption area will desorb the sulfide, and bring it to the direct combustion incinerator, ignite and burn the sulfide to generate sulfur dioxide, and then use SDS to dry it. The desulfurization system removes sulfur dioxide, and the desorbed adsorbent comes to the cooling area with the rotation of the runner, and is regenerated after being purged and cooled by air, where it can enter the adsorpti...

Embodiment 2

[0031] As shown in the figure, the enrichment rotor is filled with alkali metal modified alumina adsorbent, blast furnace gas (containing CO 2 , CO, COS, H 2 , H 2S, where COS stands for organic sulfur) is introduced into the enrichment runner, and is adsorbed in the zone, and the clean gas after adsorption enters the pipeline network to reach the gas point, the enrichment runner rotates clockwise at a rate of 15r / min, and the adsorbent is After the adsorption zone is completed, the rotor is transferred to the desorption zone. The sulfide is desorbed by hot air blowing at 700°C in the desorption zone and brought to the catalytic oxidizer, where the sulfide is catalyzed and oxidized into sulfur dioxide, and then the CFB semi-dry desulfurization system is used. Sulfur dioxide is removed, and the desorbed adsorbent comes to the cooling area with the rotation of the runner, and is regenerated after being purged and cooled by air, and can play the function of adsorbing sulfide whe...

Embodiment 3

[0033] As shown in the figure, the concentration runner is filled with ZSM-5 molecular sieve adsorbent, blast furnace gas (containing CO 2 , CO, COS, H 2 , H 2 S, where COS stands for organic sulfur) is introduced into the enrichment runner, and is adsorbed in the adsorption zone. After the adsorption, the clean gas enters the pipeline network to reach the gas consumption point, and the enrichment runner rotates clockwise at a rate of 6r / min. After the adsorption in the adsorption zone is completed, the rotor turns to the desorption zone. The hot air blowing at 400°C in the desorption zone desorbs the sulfides and takes them to the regenerative catalytic oxidizer, where the sulfides are catalyzed and oxidized into sulfur dioxide, and then lime / The gypsum desulfurization system removes sulfur dioxide, and the desorbed adsorbent comes to the cooling zone with the rotation of the runner, and is regenerated after being purged and cooled by air, and can play the function of adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com