Polyurethane diaphragm for invisible orthodontics, preparation method and application

A polyurethane film, invisible orthodontic technology, applied in the field of biomedical science and technology, can solve the problems of reducing material transparency, difficult to uniformly disperse nano-materials, affecting product stability and resilience retention, etc., to increase strength and toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

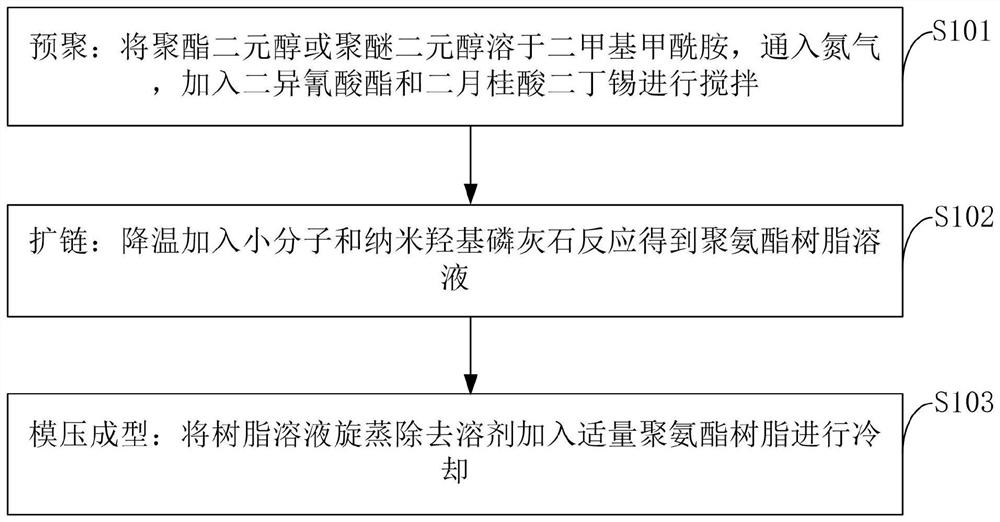

[0045] like figure 1 As shown, the preparation method of the invisible orthodontic diaphragm provided by the embodiment of the present invention comprises the following steps:

[0046] S101, prepolymerization: dissolving polyester diol or polyether diol in dimethylformamide, introducing nitrogen gas, adding diisocyanate and dibutyltin dilaurate for stirring;

[0047] S102, chain extension: cooling and adding small molecules and nano-hydroxyapatite to react to obtain a polyurethane resin solution;

[0048] S103, molding: the resin solution is rotary evaporated to remove the solvent, and an appropriate amount of polyurethane resin is added for cooling.

[0049] In step S101, according to the embodiment of the present invention, the polyester diol or polyether diol is dissolved in dimethylformamide, nitrogen is introduced, and diisocyanate and dibutyltin dilaurate are added for stirring, including:

[0050] Dissolve the polyester diol or polyether diol after drying and dewateri...

Embodiment 1

[0057] The preparation method of the invisible orthodontic diaphragm provided by the embodiment of the present invention comprises the following steps:

[0058] (1) Prepolymerization: Dissolve 240 parts of polyethylene glycol (Mn=1000) in 500 parts of dimethylformamide after vacuum dewatering, 100 parts of isophorone diisocyanate and 8 parts of dibutyl dilaurate Tin is added to the reactor, the reactor is pre-passed with nitrogen, and the prepolymer is obtained by reacting at 80-90 °C for 2 hours under stirring conditions;

[0059] (2) Chain extension: the system is cooled to 60-70°C, 60 parts of 1,4-butanediol and 60 parts of nano-hydroxyapatite are added, and the reaction is stirred for 2h;

[0060] (3) compression molding: the obtained product is distilled to remove the solvent under reduced pressure, and the polyurethane pellets are obtained through an extrusion granulator, the raw materials are added to the mold, and the pressure is maintained at 9-12 MPa for 5-8 minutes ...

Embodiment 2

[0063] The preparation method of the invisible orthodontic diaphragm provided by the embodiment of the present invention comprises the following steps:

[0064] (1) Prepolymerization: Dissolve 260 parts of polyethylene glycol (Mn=1000) in 500 parts of dimethylformamide after vacuum dewatering, 120 parts of isophorone diisocyanate and 8 parts of dibutyl dilaurate Tin is added to the reactor, the reactor is pre-passed with nitrogen, and the prepolymer is obtained by reacting at 80-90 °C for 2 hours under stirring conditions;

[0065] (2) Chain extension: the system is cooled to 60-70°C, 70 parts of 1,4-butanediol and 60 parts of nano-hydroxyapatite are added, and the reaction is stirred for 2h;

[0066] (3) compression molding: the obtained product is distilled to remove the solvent under reduced pressure, and the polyurethane pellets are obtained through an extrusion granulator, the raw materials are added to the mold, and the pressure is maintained at 9-12 MPa for 5-8 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com