Long-chain organosilicon-modified exposed waterborne polyurethane emulsion and preparation method thereof

A water-based polyurethane, silicone technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor elongation at break, high water absorption, low tensile strength, etc., achieve excellent mechanical properties, simple steps , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

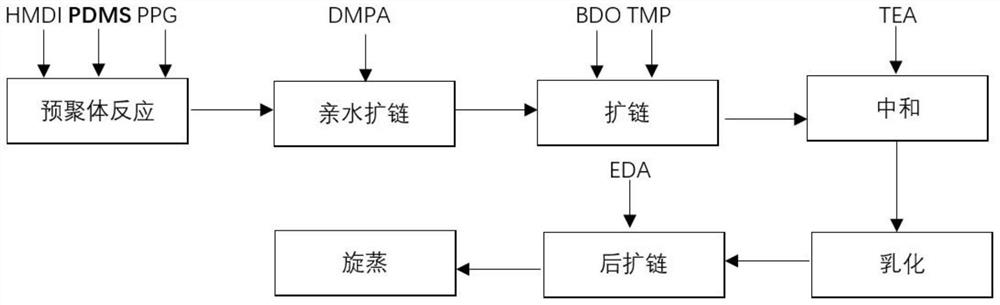

Method used

Image

Examples

Embodiment 1

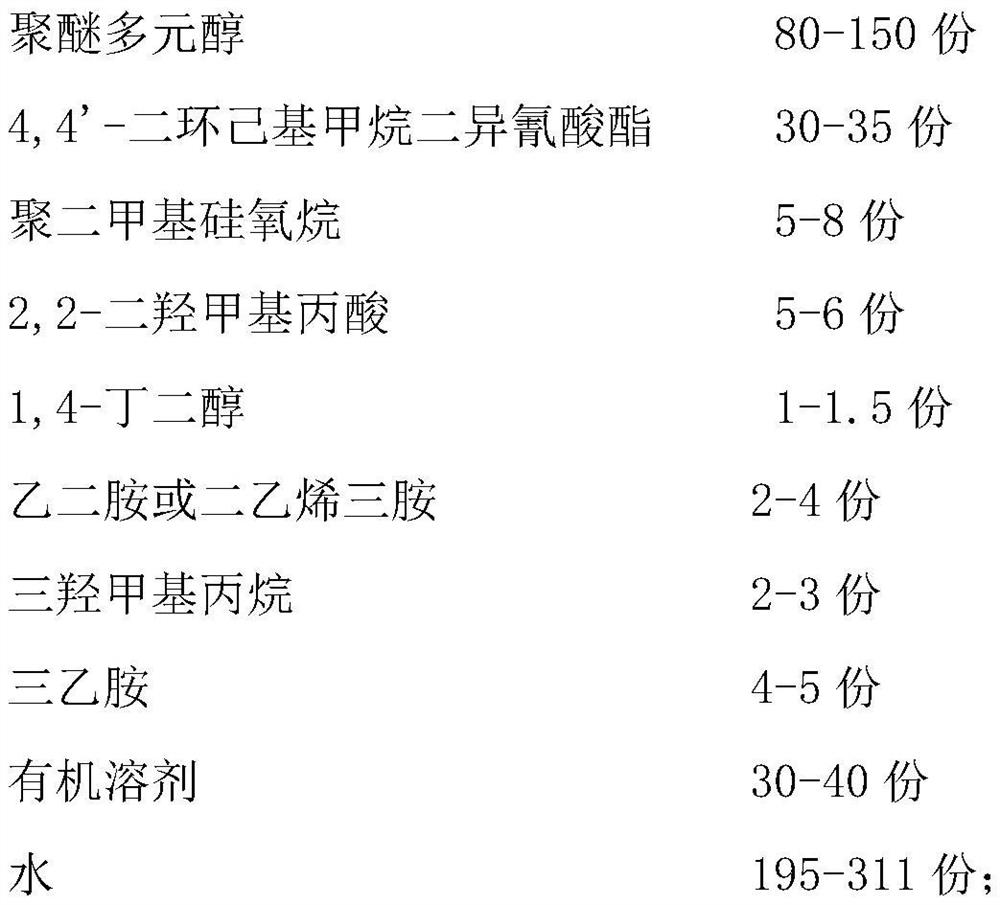

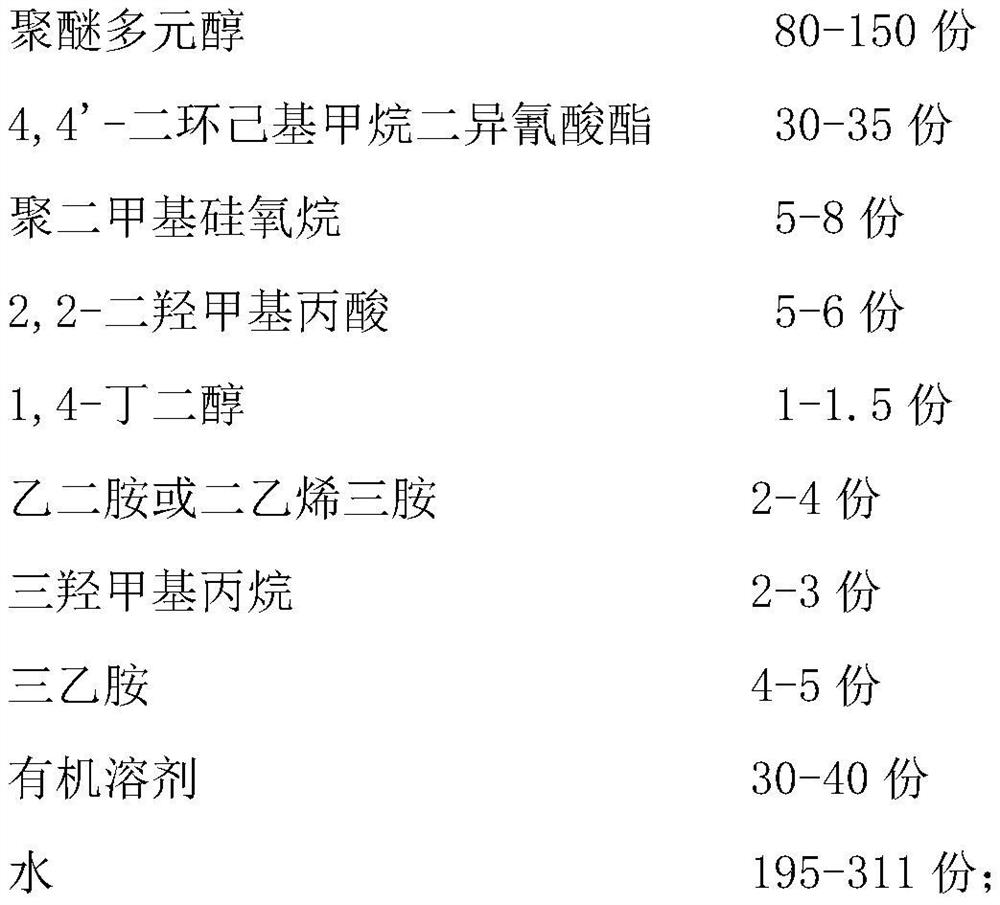

[0031] A long-chain organosilicon-modified exposed water-based polyurethane emulsion according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0032]

[0033] Among them, polydimethylsiloxane, M W = 4200 g / mol.

[0034] The polyether polyol is polypropylene glycol.

[0035] Described organic solvent is acetone.

[0036] The water is deionized water.

[0037] The preparation method of the long-chain organosilicon-modified exposed water-based polyurethane emulsion mainly includes the following steps in sequence:

[0038] (1) React polyether polyol, 4,4'-dicyclohexylmethane diisocyanate and polydimethylsiloxane at 60°C for 1 hour under nitrogen protection;

[0039] (2) Add 2,2-dimethylolpropionic acid to the reactant obtained in step (1), heat up to 70°C for 1 hour;

[0040] (3) Cool down to 50°C, add an organic solvent to the reactant obtained in step (2), and stir for 0.5h;

[0041] (4)...

Embodiment 2

[0046] A long-chain organosilicon-modified exposed water-based polyurethane emulsion according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0047]

[0048] Among them, polydimethylsiloxane, M W = 4000 g / mol.

[0049] The polyether polyol is polypropylene glycol.

[0050] Described organic solvent is acetone.

[0051] The water is deionized water.

[0052] The preparation method of the long-chain organosilicon-modified exposed water-based polyurethane emulsion mainly includes the following steps in sequence:

[0053] (1) React polyether polyol, 4,4'-dicyclohexylmethane diisocyanate and polydimethylsiloxane at 55°C for 1.2h under nitrogen protection;

[0054] (2) Add 2,2-dimethylolpropionic acid to the reactant obtained in step (1), and raise the temperature to 68°C for 1.2h;

[0055] (3) Cool down to 48° C., add an organic solvent to the reactant obtained in step (2), and stir for 1 h...

Embodiment 3

[0061] A long-chain organosilicon-modified exposed water-based polyurethane emulsion according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0062]

[0063] Among them, polydimethylsiloxane, M W = 4400 g / mol.

[0064] The polyether polyol is polypropylene glycol.

[0065] Described organic solvent is acetone.

[0066] The water is deionized water.

[0067] The preparation method of the long-chain organosilicon-modified exposed water-based polyurethane emulsion mainly includes the following steps in sequence:

[0068] (1) React polyether polyol, 4,4'-dicyclohexylmethane diisocyanate and polydimethylsiloxane at 65°C for 0.8h under nitrogen protection;

[0069] (2) Add 2,2-dimethylolpropionic acid to the reactant obtained in step (1), and raise the temperature to 72°C for 0.8h;

[0070] (3) Cool down to 49°C, add an organic solvent to the reactant obtained in step (2), and stir for 1.5h;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com