High-filling ultrahigh-heat-conducting epoxy resin material and preparation method thereof

An epoxy resin, ultra-high technology, applied in the field of high-filled ultra-high thermal conductivity epoxy resin materials and preparation, can solve the problem that thermal conductivity cannot meet the needs of use, and achieve good thermal conductivity, ensure the process, and ensure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of highly filled ultrahigh thermal conductivity epoxy resin material comprises the following steps:

[0051] First, 15-25% of boron nitride with a particle size of 30-70nm, 50-65% of the large particle size aluminum oxide with a particle size of 80-120μm, and 6-14% of the small particle size type with a particle size of 40-60nm Aluminum oxide, 10-20% aluminum nitride with a particle size of 10-30nm, and 4-8% zinc oxide heat-conducting powder with a particle size of 80-120nm are mixed according to the proportion and then poured into a tray and placed in an oven. Dehumidify at 145°C for 120-200min, then cool naturally in an oven. The humidity in the oven room is below 30%, and the composite heat-conducting powder is obtained after drying.

[0052] Secondly, pour the composite heat-conducting powder into the milling, dispersing and modifying all-in-one machine, add titanium / aluminate coupling agent, aliphatic epoxy resin, and also add silane couplin...

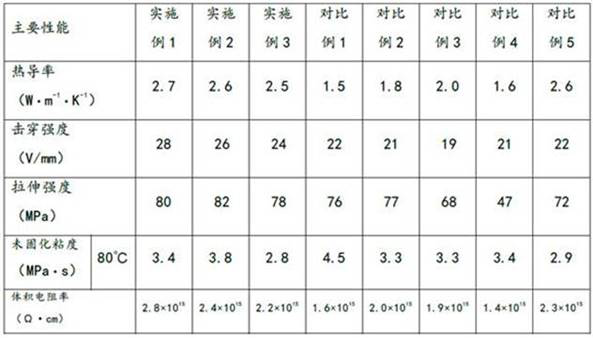

Embodiment 1

[0056] A high-filling super-high thermal conductivity epoxy resin material, which is prepared from component A and component B; component A is a mixture of epoxy resin base material and modified thermal conductive powder; component B is composed of curing agent, accelerator A mixture of mixing aids and modified thermally conductive powders consisting of a curing agent and a toughening agent; the mass percentage ratio of the curing agent, the accelerator and the toughening agent is 2:1.5:1.

[0057] Wherein, the epoxy resin base material is tetrabromobisphenol A epoxy resin; the curing agent is an acid anhydride curing agent, which is methyl hexahydroanhydride; the accelerator is an imidazole polymer; the toughening agent is an active toughening agent; The active toughening agent is prepolymer polyurethane.

[0058] The mass percentage ratio of A component to the B component is 1:1; the mass percentage ratio of epoxy resin base material and modified thermal conductive powder in...

Embodiment 2

[0067] A high-filling super-high thermal conductivity epoxy resin material, which is prepared from component A and component B; component A is a mixture of epoxy resin base material and modified thermal conductive powder; component B is composed of curing agent, accelerator A mixture of mixing aids and modified thermally conductive powders consisting of a curing agent and a toughening agent; the mass percentage ratio of the curing agent, the accelerator and the toughening agent is 2.5:1.5:1.

[0068] Among them, the epoxy resin is hydrogenated bisphenol A epoxy resin; the curing agent is an acid anhydride curing agent, which is methyl tetrahydroanhydride; the accelerator is a complex cation; the toughening agent is an active toughening agent; The agent is polythiol and prepolymer polyurethane.

[0069]The mass percentage ratio of A component to the B component is 1.2:1; the mass percentage ratio of epoxy resin base material and modified thermal conductive powder in A component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com