Thermo-sensitive dye microcapsule material, preparation method and thermo-sensitive coating

A technology of heat-sensitive dyes and microcapsules, which can be used in microcapsule preparations, microsphere preparation, fiber raw material processing, etc., and can solve problems such as lack of layering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

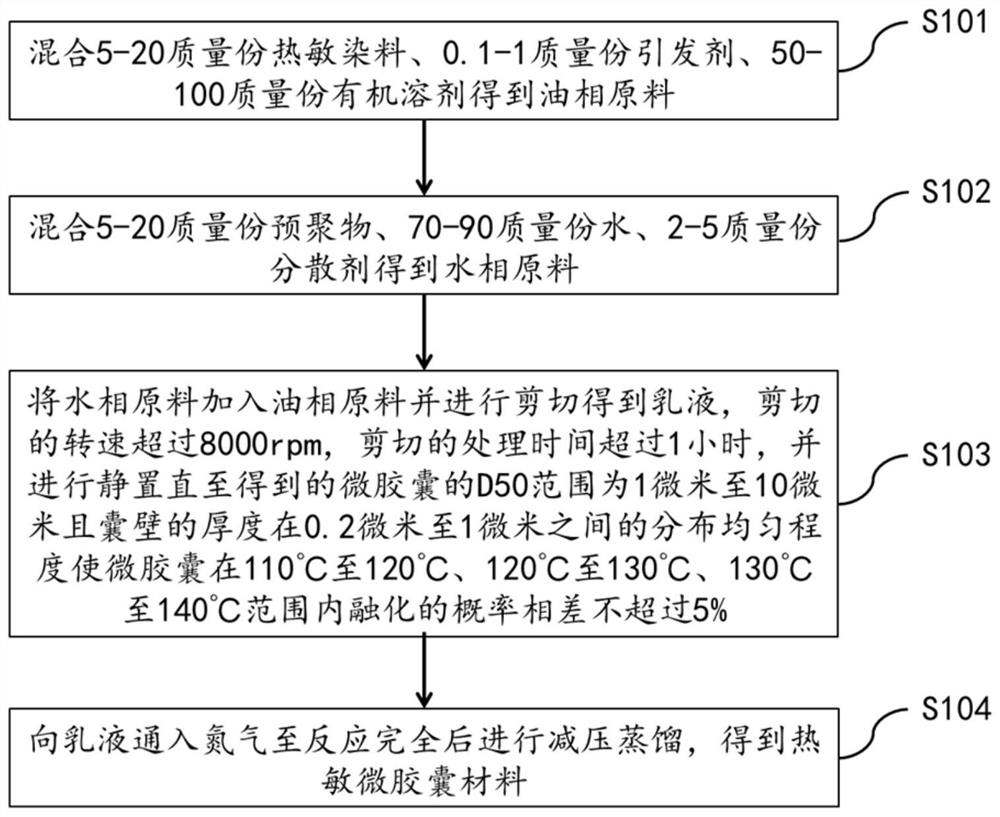

Method used

Image

Examples

preparation example Construction

[0052] The main difference between the technical solution provided by this application and the existing technical solution for preparing microcapsules is that the step of standing still is added. In the existing technical solution, shearing is expected to obtain microcapsules with a relatively uniform distribution. To solve the problem of lack of color scale in the color development of microcapsules, a standing step is set up to take advantage of the fact that the oil phase droplets have a tendency to repolymerize in the water phase, and through standing still, some of the small droplets formed by shearing are repolymerized , and enable the prepolymer in the water phase to fully react to obtain a wide and uniform distribution range of the cyst wall thickness.

[0053] In the step of vacuum distillation, the temperature of the emulsion can be controlled at 40° C. to 60° C. so as to speed up the speed of vacuum distillation without destroying the capsule wall of the microcapsules...

Embodiment 1

[0059] A method for preparing heat-sensitive paint, comprising the steps of:

[0060] Prepare oil phase raw materials: mix 5 parts by mass of o-hydroxymethylbenzoic acid lactone, 0.1 parts by mass of azobisisobutyronitrile and 50 parts by mass of methyl ethyl ketone, heat to 50°C, and stir for not less than 25 minutes until they are evenly stirred to obtain oil raw materials;

[0061] Configure the water phase raw material: mix 5 parts by mass of polyethylene glycol dimethacrylate, polycaprolactam, poly-N-isopropylacrylamide and polyethylene glycol block copolymer 1:1:1 mixture, 70 parts by mass of deionized water and 2 parts by mass of polyvinyl alcohol are raw materials in the aqueous phase;

[0062] Shear emulsification: add the water phase raw material to the oil phase raw material, use the Shanghai Huxie HR500 high-speed shearing machine produced by Shanghai Huxie to shear the mixture of the oil phase raw material and the water phase raw material, the shearing speed is 1...

Embodiment 2

[0066] Prepare the oil phase raw materials: mix 7 parts by mass of crystal violet lactone, 0.5 parts by mass of azobisisobutyronitrile and 50 parts by mass of butanone, heat to 50°C, and stir for not less than 25 minutes until uniformly stirred to obtain the oil phase raw materials;

[0067] Configure the water phase raw material: mix 10 parts by mass of polyethylene glycol dimethacrylate and a 1:1 mixture of polycaprolactam, 70 parts by mass of deionized water and 4 parts by mass of polyvinyl alcohol, in the water phase raw material;

[0068] Shear emulsification: add the water phase raw material to the oil phase raw material, use the Shanghai Huxie HR500 high-speed shearing machine produced by Shanghai Huxie to shear the mixture of the oil phase raw material and the water phase raw material, the shearing speed is 10000rpm, and the shearing speed is 10000rpm. Cut processing time is 1.5 hours, then let stand for 30 minutes;

[0069] Distillation under reduced pressure: Nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com