Low-smoke, halogen-free and flame-retardant double-layer insulated wire

A technology of double-layer insulation and wires, which is applied in the direction of insulated cables, insulated conductors, circuits, etc., can solve the problems of low thermosetting, decreased insulation resistance, and poor moisture-proof and waterproof performance of low-smoke, halogen-free, flame-retardant polyolefin insulated wires, etc., to achieve Effects of improving insulation performance, reducing production costs, and reducing fire phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

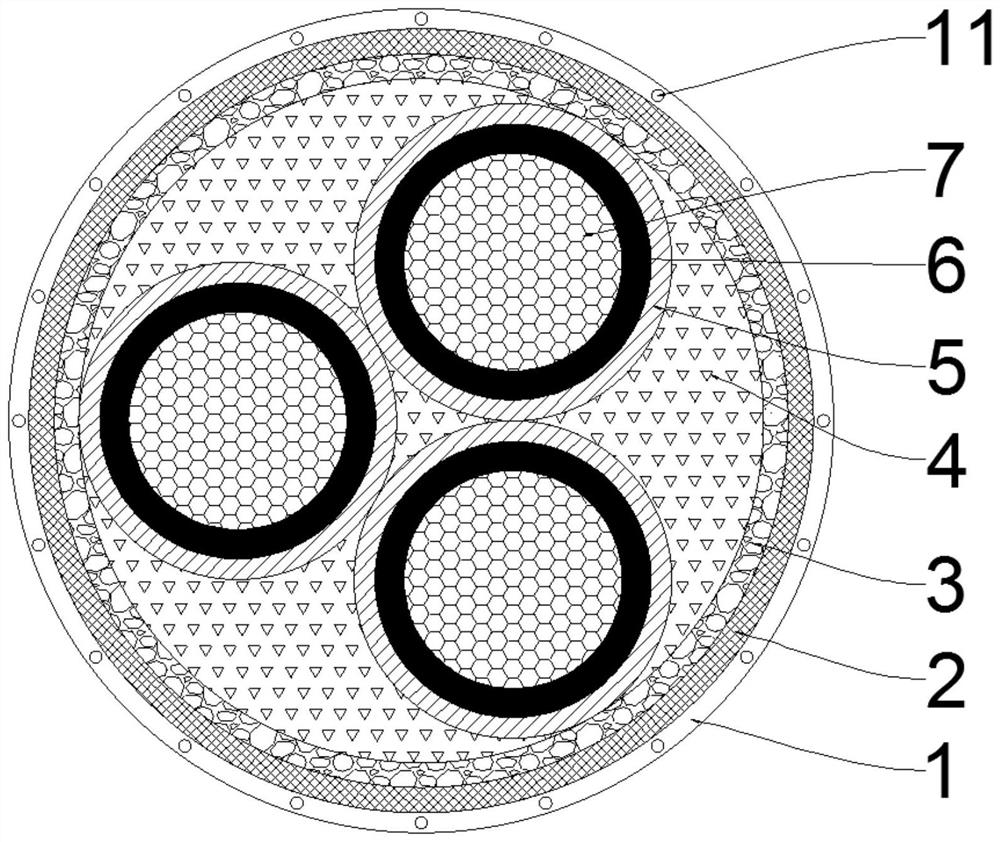

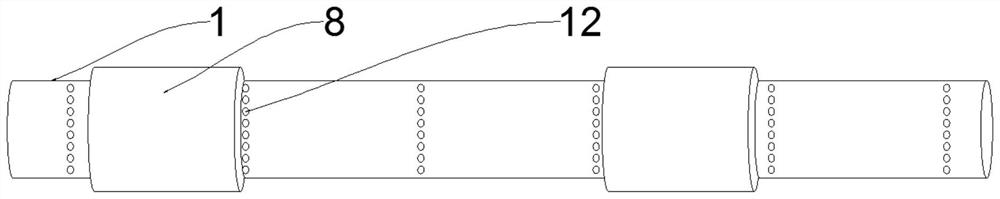

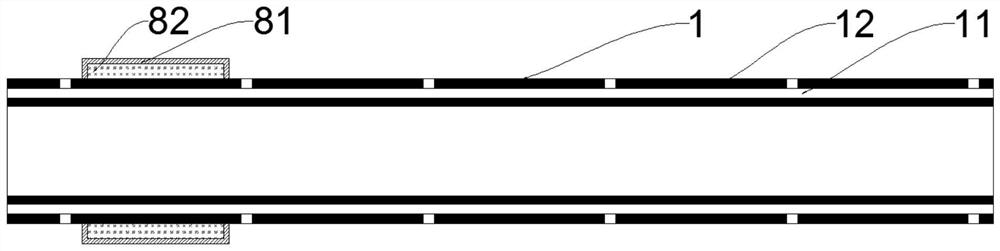

[0028] Example 1: A low-smoke, halogen-free, flame-retardant double-layer insulated wire with good flame retardancy, such as figure 1 As shown, it includes outer protective cover 1, filling cotton layer 2, waterproof layer 3 and multiple inner wires, and then combined figure 2 and image 3 It can be seen that the equidistant cover on the outer wall of the outer protective cover 1 is provided with a plurality of fire extinguishing packages 8. The fire extinguishing package 8 is composed of a plastic cover 81 and a fire extinguishing dry powder 82. The dry powder is made of ammonium phosphate. Open flames to prevent fire from spreading and reduce damage.

[0029] Preferably, a plurality of transverse channels 11 are equidistantly arranged in the outer layer protective cover 1 in the circumferential direction, and a plurality of ventilation holes 12 are provided equidistantly on the surface of the outer layer protective cover 1 , and the bottom of the ventilation holes 12 is co...

Embodiment 2

[0041] Example 2, a low-smoke, halogen-free, flame-retardant double-layer insulated wire with good flame retardancy, differs from Example 1 in that the formula of the high-temperature-resistant, low-smoke, halogen-free insulating material is as follows:

[0042] Ethylene-vinyl acetate copolymer: 10kg, polyethylene: 4kg, ethylene-octene copolymer thermoplastic elastomer: 3kg, compatibilizer: 3kg, aluminum hydroxide: 30kg, chemical magnesium: 2kg, silicone: 0.6kg, anti Oxygen agent 1010: 0.10kg, 172 silane: 0.2kg, BP initiator: 0.5kg, rheology agent: 0.2kg.

Embodiment 3

[0043] Example 3, a low-smoke, halogen-free, flame-retardant double-layer insulated wire with good flame retardancy, differs from Example 1 in that the formula of the high-temperature-resistant, low-smoke, halogen-free insulating material is as follows:

[0044] Ethylene-vinyl acetate copolymer: 20kg, polyethylene: 5kg, ethylene-octene copolymer thermoplastic elastomer: 6kg, compatibilizer: 6kg, aluminum hydroxide: 60kg, chemical magnesium: 4kg, silicone: 1kg, antioxidant Agent 1010: 0.2kg, 172 silane: 0.4kg, BP initiator: 0.9kg, rheology agent: 0.4kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com