Built-in circulating passive cooling module and method for air-cooled small-power solid laser of all-in-one machine

A solid-state laser and passive cooling technology, which is applied in the direction of laser cooling devices, lasers, laser components, etc., can solve problems such as easy fogging, deterioration of the output light mode of the laser beam, and shortened service life of the laser. small resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with examples and specific implementation methods. However, it should not be understood that the scope of the above-mentioned themes of the present invention is limited to the following embodiments, and all technologies realized based on the contents of the present invention belong to the scope of the present invention.

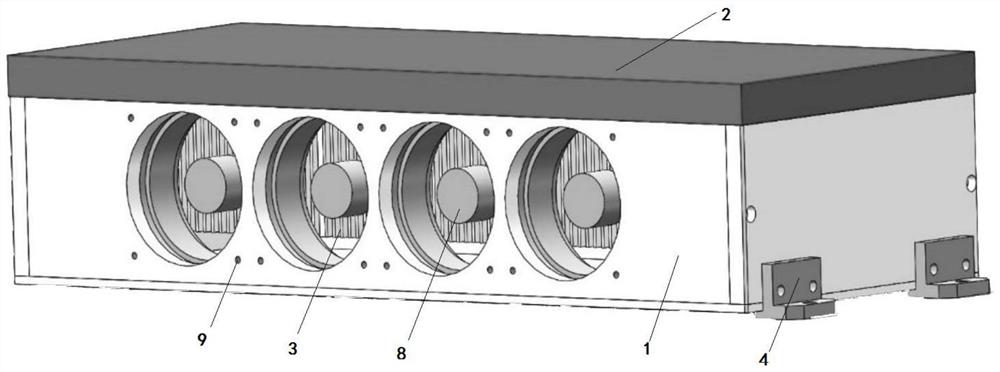

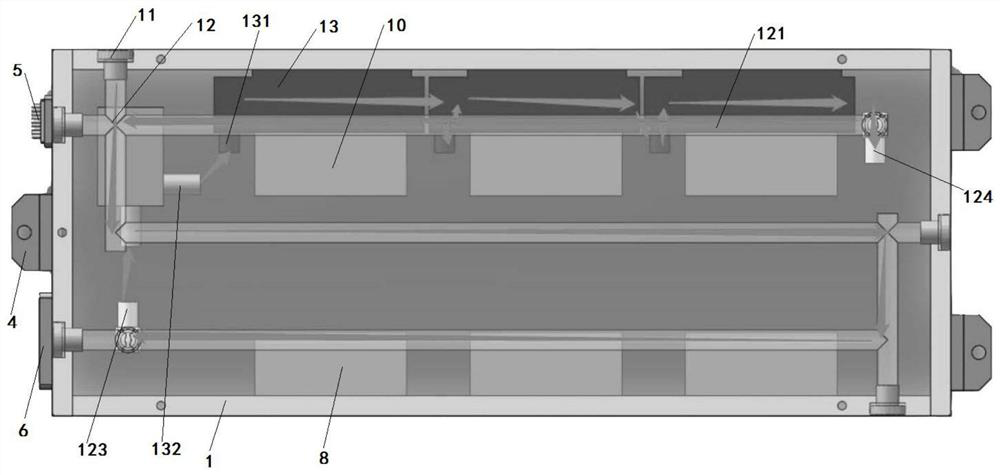

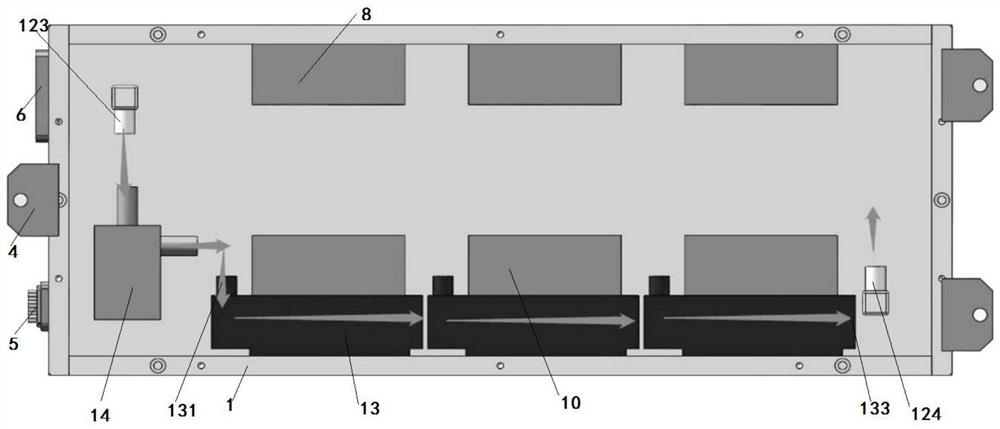

[0032] Such as Figure 1-5 It is a schematic structural diagram of the built-in circulation passive cooling module and method for the air-cooled low-power solid-state laser of the all-in-one machine of the present invention. The built-in circulation passive cooling module for the all-in-one air-cooled low-power solid-state laser of the present invention includes a module The group seat 1, the top of the module seat 1 is provided with a cooling base plate 2 for installing the laser, the cooling base plate 2 is provided with an S-shaped water channel 12, and the module seat 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com