Boron nitride filled heat conduction interface material and preparation method thereof

An interface material, boron nitride technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of insufficient wetting of boron nitride powder, crushing of elongation products, and decline in thermal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A boron nitride filled thermally conductive interface material comprising:

[0057] Filler skeleton and silicone resin matrix;

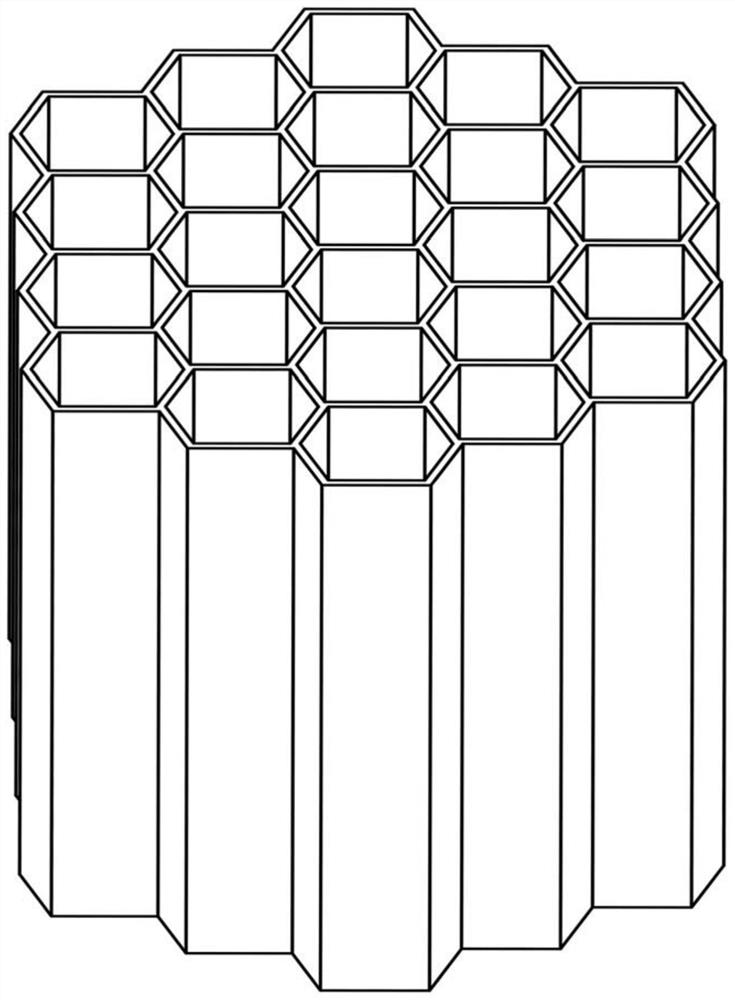

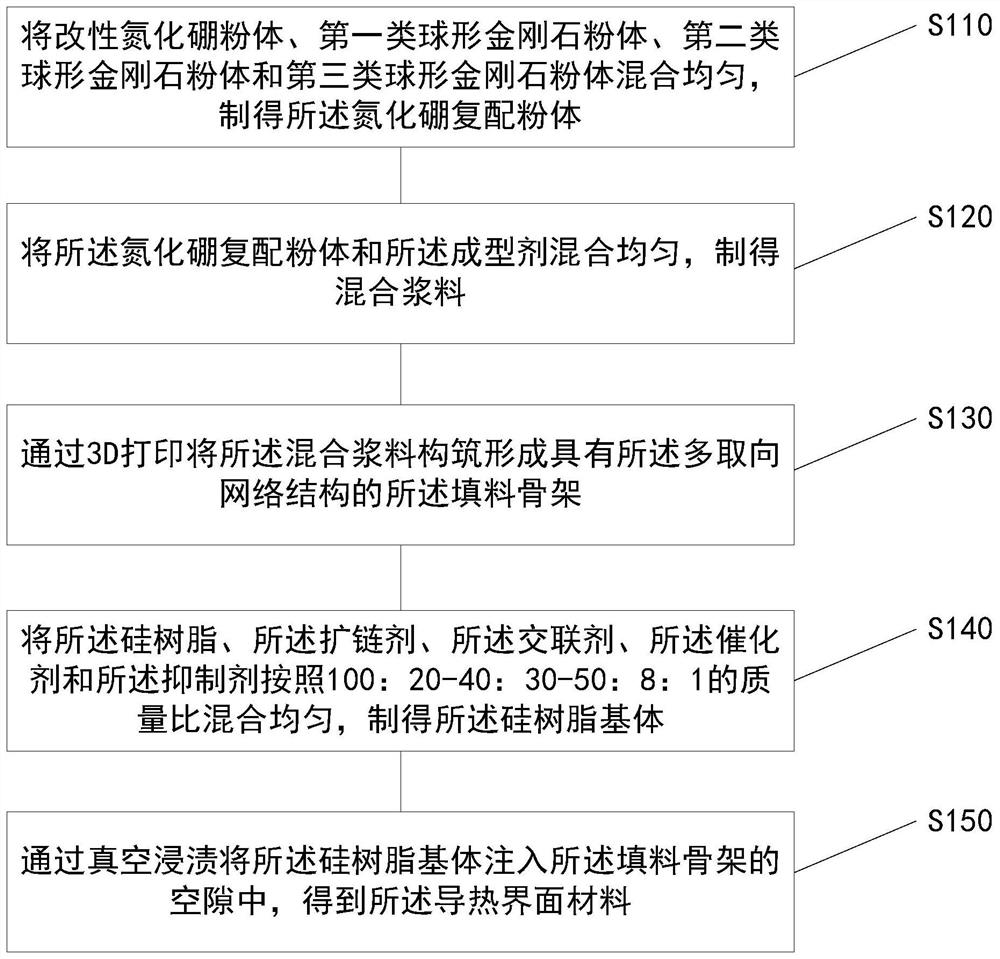

[0058] The filler skeleton is a honeycomb network structure; the honeycomb network structure is formed by extending a mesh plane in a vertical direction; wherein, the mesh plane is formed by periodically arranging a number of hollow regular hexagons;

[0059] The silicone resin matrix includes silicone resin, chain extender, cross-linking agent, catalyst and inhibitor; the silicone resin is double-sealed vinyl silicone oil from which all the first siloxane and more than half of the second siloxane are removed; Wherein, the first siloxane includes siloxane having 3-20 silicon atoms, and the second siloxane includes siloxane having 20-50 silicon atoms.

Embodiment 2

[0061] A boron nitride filled thermally conductive interface material comprising:

[0062] Filler skeleton and silicone resin matrix;

[0063] The filler skeleton is a honeycomb network structure; the honeycomb network structure is formed by extending a mesh plane in a vertical direction; wherein, the mesh plane is formed by periodically arranging a number of hollow regular hexagons;

[0064] The silicone resin matrix includes silicone resin, chain extender, cross-linking agent, catalyst and inhibitor; the silicone resin is double-sealed vinyl silicone oil from which all the first siloxane and more than half of the second siloxane are removed; Wherein, the first siloxane includes siloxane having 3-20 silicon atoms, and the second siloxane includes siloxane having 20-50 silicon atoms.

Embodiment 3

[0066] A boron nitride filled thermally conductive interface material comprising:

[0067] Filler skeleton and silicone resin matrix;

[0068] The filler skeleton is a honeycomb network structure; the honeycomb network structure is formed by extending a mesh plane in a vertical direction; wherein, the mesh plane is formed by periodically arranging a number of hollow regular hexagons;

[0069] The silicone resin matrix includes silicone resin, chain extender, cross-linking agent, catalyst and inhibitor; the silicone resin is double-sealed vinyl silicone oil from which all the first siloxane and more than half of the second siloxane are removed; Wherein, the first siloxane includes siloxane having 3-20 silicon atoms, and the second siloxane includes siloxane having 20-50 silicon atoms.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com