High-barrier antibacterial polycaprolactone emulsion as well as preparation method and application thereof

A polycaprolactone, high-barrier technology, used in polyester coatings, coatings, biocide-containing paints, etc., can solve the problems of water resistance and reduced barrier performance, achieve good water resistance, improve barrier performance, improve The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

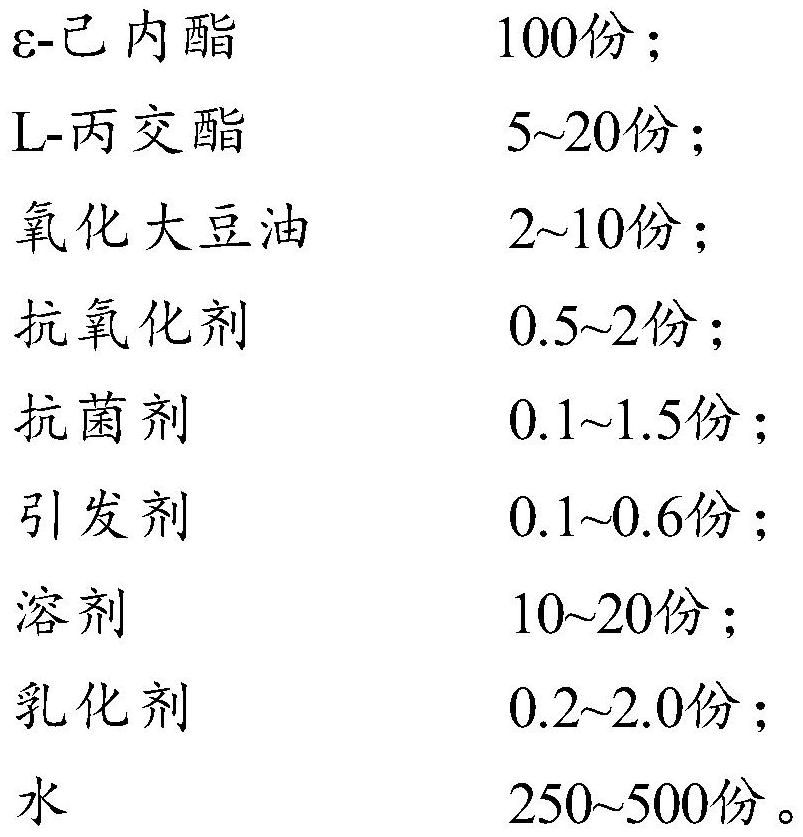

[0043] The present invention provides a kind of preparation method of the high-barrier antibacterial polycaprolactone emulsion described in above-mentioned technical scheme, comprising:

[0044] mixing L-lactide, solvent, caprolactone, epoxidized soybean oil, emulsifier and initiator to obtain a pre-emulsified emulsion;

[0045] mixing the pre-emulsified emulsion with water to obtain an emulsified emulsion;

[0046] reacting the emulsified emulsion to obtain a reaction product;

[0047] The reaction product is mixed with an antioxidant and an antibacterial agent to obtain a high-barrier antibacterial polycaprolactone emulsion.

[0048] In the present invention, the preparation method of the pre-emulsified emulsion preferably comprises:

[0049] Add L-lactide into the solvent and heat to dissolve, then add ε-caprolactone, then add epoxidized soybean oil, emulsifier, and initiator in sequence, and carry out stirring and pre-emulsification to obtain a pre-emulsified emulsion. ...

Embodiment 1

[0069] In parts by weight, add 10 parts of L-lactide to 20 parts of ethyl acetate solvent, heat to 55°C and stir to dissolve, add the dissolved solution to 100 parts of ε-caprolactone, and then add 3 parts of cyclic Oxygenated soybean oil, 0.6 part emulsifier 0.3 parts of organic phosphazene superbase CTPB were sequentially added to the solution for pre-emulsification with stirring at a stirring speed of 400 rpm to obtain a pre-emulsified emulsion.

[0070] Add 360 parts of deionized water into the reaction kettle, slowly add the pre-emulsified emulsion while stirring, the stirring speed is 200 rpm, and the adding time is 15 minutes to obtain the emulsified emulsion.

[0071] The reactor was evacuated to below 1Kpa, and nitrogen gas was introduced, and this was repeated 5 times.

[0072] Under nitrogen condition, heat to 65°C and react for 2.5 hours to obtain an emulsion.

[0073] After the emulsion was cooled to normal temperature, 0.9 part of tea polyphenols and 1 part of...

Embodiment 2

[0075] In parts by weight, 15 parts of L-lactide was added to 25 parts of ethyl acetate solvent, heated to 55°C and stirred to dissolve, the dissolved solution was added to 100 parts of ε-caprolactone, and then 3.5 parts of cyclic Oxygenated soybean oil, 0.6 part emulsifier 0.4 parts of organic phosphazene superbase CTPB were sequentially added into the solution for pre-emulsification with stirring at a stirring speed of 400 rpm to obtain a pre-emulsified emulsion.

[0076] Add 400 parts of deionized water into the reaction kettle, slowly add the pre-emulsified emulsion while stirring, the stirring speed is 200 rpm, and the adding time is 15 minutes to obtain the emulsified emulsion.

[0077] The reactor was evacuated to below 1Kpa, and nitrogen gas was introduced, and this was repeated 5 times.

[0078] Under nitrogen condition, heat to 68°C and react for 2.2 hours to obtain an emulsion.

[0079] After the emulsion was cooled to normal temperature, 1.2 parts of phytic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com