Optical fiber sensing fabric for pulse and oxyhemoglobin saturation detection and preparation method

An optical fiber sensing and saturation technology, applied in the field of pulse and blood oxygen saturation sensors, can solve problems such as difficult fabric bonding, achieve good contact comfort, improve signal-to-noise ratio, and facilitate mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

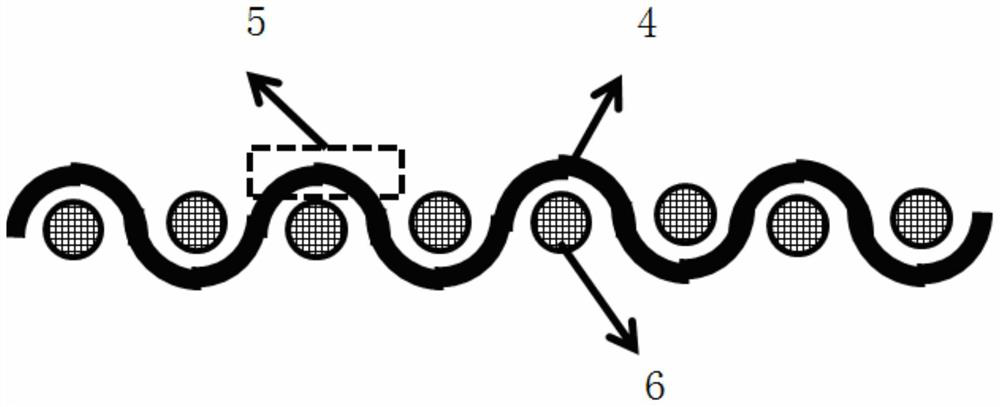

[0039] Embodiment 1: This embodiment demonstrates a preparation method of an optical fiber pulse oximeter sensor fabric based on a weaving process with a microbend convex structure.

[0040] The weft yarn of the optical fiber sensing fabric is made of 1000 μm PMMA polymer optical fiber, the rest of the weft and warp yarns are made of nylon viscose blended yarn, and the light-blocking yarn between the two optical fibers is twisted yarn of 20 nylon viscose blended yarns. The diameter is within 1 to 2mm. Pulse fabric is woven on a dobby loom.

[0041] Both the side-emitting optical fiber and the side-sensitive optical fiber use polymer optical fibers, and a microbend convex structure is formed on the polymer optical fibers by hot pressing.

[0042] Put the polymer optical fiber into the mold with micro-bending grooves, and use the hot air device to heat the polymer optical fiber locally. When the polymer optical fiber in the heating area is softened, it is hot-pressed and solidi...

Embodiment 2

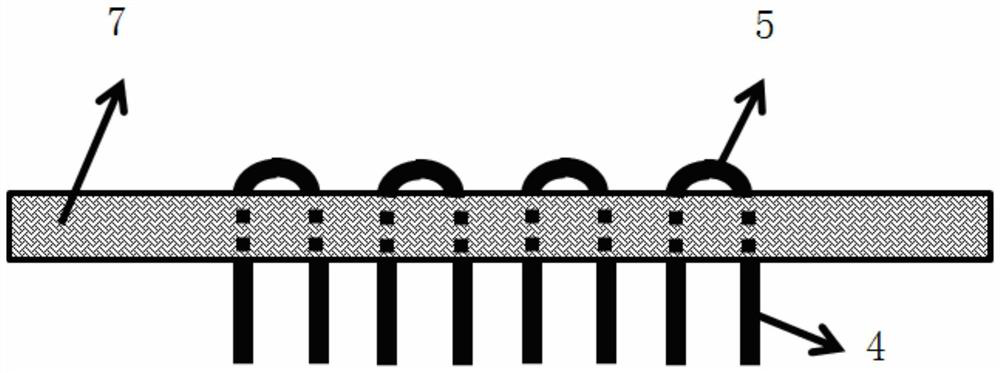

[0048] Embodiment 2: This embodiment demonstrates a preparation method of an optical fiber pulse oximeter sensor fabric based on a laser grooved structure knitting process.

[0049] The optical fiber is a PMMA polymer optical fiber with a diameter of 1000 μm, and the light-blocking yarn is a ply-twisted yarn of 15 or 20 low-elasticity and high-temperature-resistant viscose / nylon yarns, with a diameter of 1 to 2 mm. The remaining yarns are cotton yarns with a fineness of 50 tex / 3.

[0050] The fabric is woven on a warp knitting sample loom, the machine number is E12, the knitting needles are latch needles, and the rear guide frame is used (the yarn does not need to be warped), and the warp is passively let off and directly drawn by the guide frame. Go to the weaving area and weave.

[0051] The overall fabric adopts warp knitted fabric, which has the advantages of stable size, crisp fabric, not easy to fall off, etc. At the same time, it has the characteristics of good air per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com