Spherical tip micro-nano thermocouple probe and preparation method thereof

A thermocouple, cutting-edge technology, applied in the direction of thermometers that are directly sensitive to heat/magnetic elements, measuring heat, using electrical devices, etc., can solve the problem of temperature measurement of droplets that are not suitable for shapes, low temperature sensitivity, and easily damaged rigidity and other problems, to achieve the effect of no thermal hysteresis, strong linear characteristics, high thermoelectric repeatability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

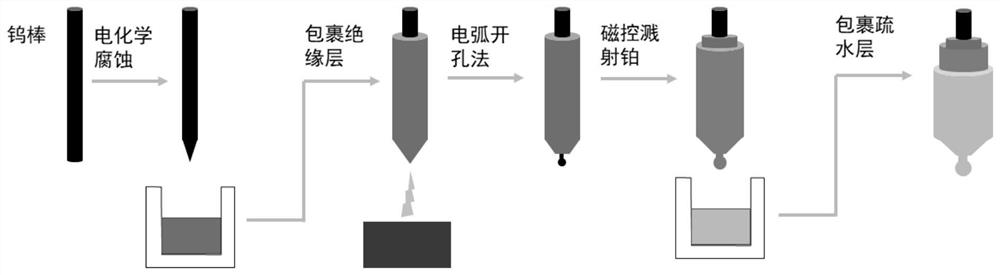

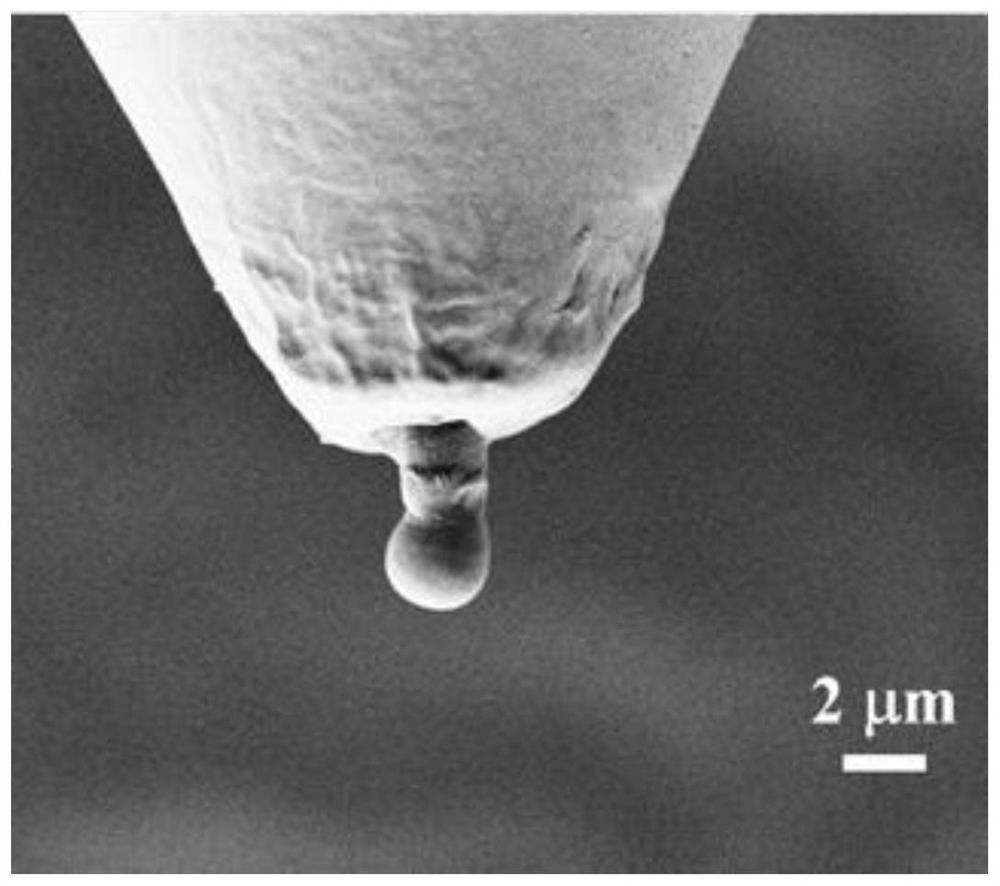

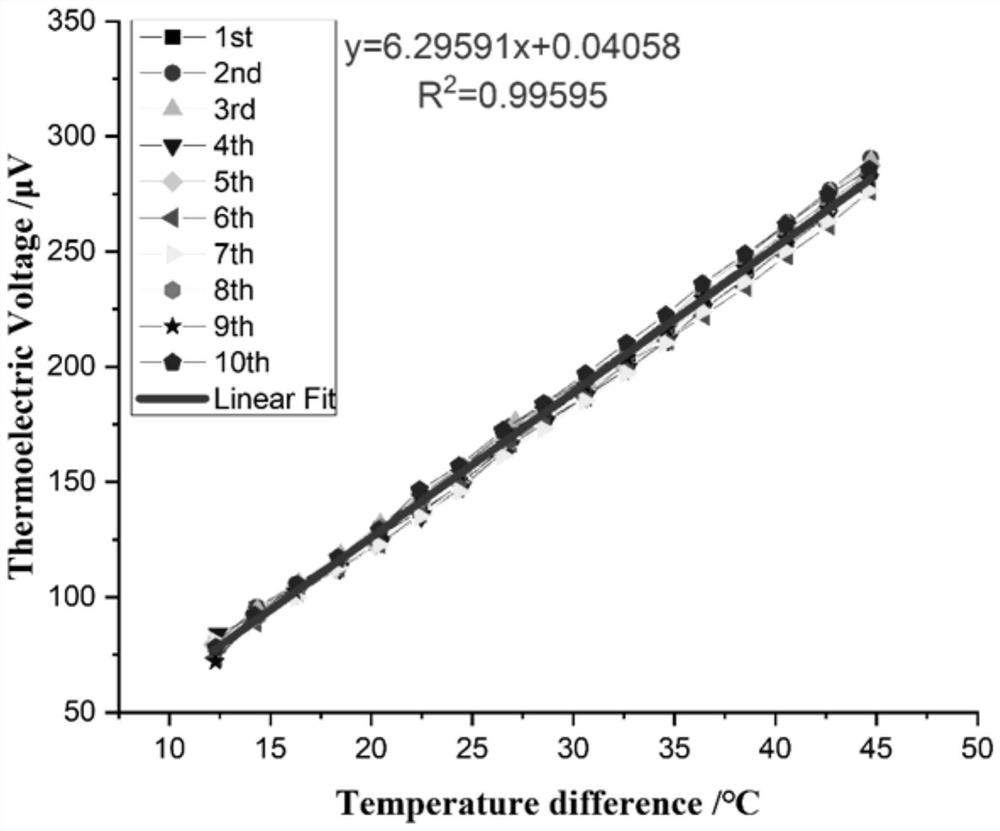

[0030] Preparation of a spherical-tip micro-nano thermocouple probe for temperature measurement of water droplets, such as figure 1 shown, including the following steps:

[0031] (1) Put a tungsten rod with a diameter of 0.3mm and a length of 70mm cleaned on the surface into a 3mol / L sodium hydroxide solution, and use it as an anode for electrochemical corrosion to obtain a tip with a curvature radius of 2nm-5nm;

[0032] (2) Put the tipped tungsten probe into the tetrahydrofuran solution containing 100g / L polyurethane and slowly lift it up to obtain the tungsten probe wrapped by the back end; put the tip of the tungsten probe wrapped by the back end into the solution containing 100g / L polyurethane The tetrahydrofuran solution and lift it up slowly to get a tungsten probe completely wrapped at the front and back ends;

[0033] (3) The fully wrapped tungsten probe is used as one pole of the tip discharge, and the electrode is used as the other pole of the tip discharge, and a ...

Embodiment 2

[0041] A preparation of a spherical tip micro-nano thermocouple probe for temperature measurement of water droplets, comprising the steps of:

[0042] (1) Put a tungsten rod with a diameter of 0.3mm and a length of 70mm cleaned on the surface into a 3mol / L sodium hydroxide solution, and use it as an anode for electrochemical corrosion to obtain a tip with a curvature radius of 2nm-5nm;

[0043] (2) Put the tipped tungsten probe into the tetrahydrofuran solution containing 100g / L polyurethane and slowly lift it up to obtain the tungsten probe wrapped by the back end; put the tip of the tungsten probe wrapped by the back end into the solution containing 100g / L polyurethane The tetrahydrofuran solution and lift it up slowly to get a tungsten probe completely wrapped at the front and back ends;

[0044] (3) The fully wrapped tungsten probe is used as one electrode of the tip discharge, and the electrode is used as the other electrode of the tip discharge, and a voltage of 600V is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com