Rubber waterproof coiled material and preparation method thereof

A waterproofing membrane and rubber technology, applied in the field of waterproofing membranes, can solve the problems such as the inability of the adhesive and the adhesive tape to have the same service life of the membranes, the poor bonding of the overlapping parts of the membranes, and the impact on the waterproofing effect of the membranes. Strengthening effect, welding stability promotion, easy handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The first aspect of the embodiment of the present application provides a method for preparing a rubber waterproof membrane, including:

[0034] gelling the first mixture of polyolefin thermoplastic elastomer, polyolefin thermal welding agent and reinforcing agent under the first environmental condition to obtain the first colloid;

[0035] granulating the first colloid to obtain the first granular material;

[0036] The rubber waterproof roll material is obtained by mixing and extruding the first granular material, low-density polyethylene and composite anti-oxidation masterbatch.

[0037] The preparation method of the rubber waterproof membrane provided by this application can be prepared by gelling, granulating and extruding polyolefin thermoplastic elastomer, polyolefin thermal welding agent, low-density polyethylene and reinforcing agent. Obtain a rubber waterproof membrane with weldability, in which the granulation treatment can make the reinforcing agent and poly...

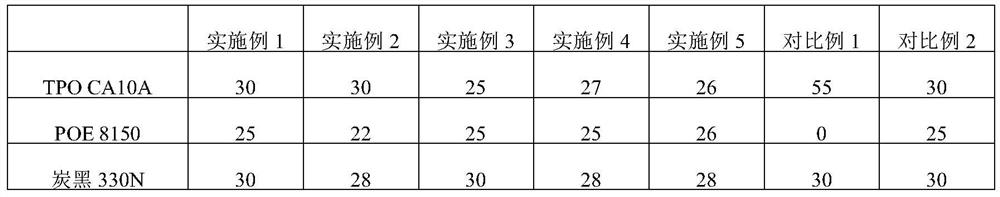

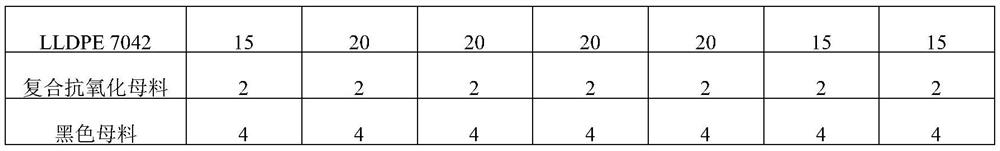

Embodiment 1

[0061] A kind of rubber waterproof coiled material, raw material comprises by weight:

[0062] Polyolefin thermoplastic elastomer TPO CA10A, 30 parts; polyolefin thermal welding agent POE 8150, 25 parts; carbon black 330N, 30 parts; linear low density polyethylene LLDPE 7042, 15 parts; composite antioxidant masterbatch, 2 parts; black masterbatch, 4 parts.

Embodiment 2

[0064] A kind of rubber waterproof coiled material, raw material comprises by weight:

[0065] Polyolefin thermoplastic elastomer TPO CA10A, 30 parts; polyolefin thermal welding agent POE 8150, 22 parts; carbon black 330N, 28 parts; linear low density polyethylene LLDPE 7042, 20 parts; composite antioxidant masterbatch, 2 parts; black masterbatch, 4 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com