Method for cleaning surface oil dirt of lead alloy grid produced through continuous casting

A surface oil stain and lead alloy technology, which is applied in the field of oil stain cleaning on the surface of lead alloy grids, can solve the problems of ultrasonic degreasing noise, employee health impact, irritating odor, etc., to achieve surface moisture removal, oil removal and decontamination Strong ability, excellent leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

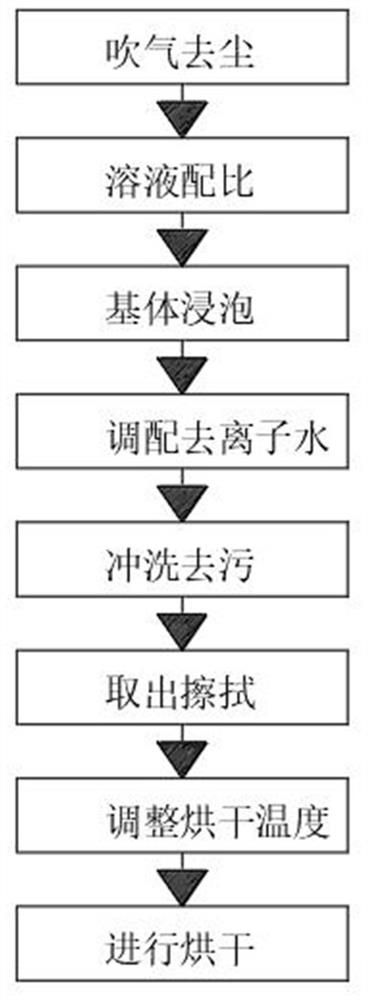

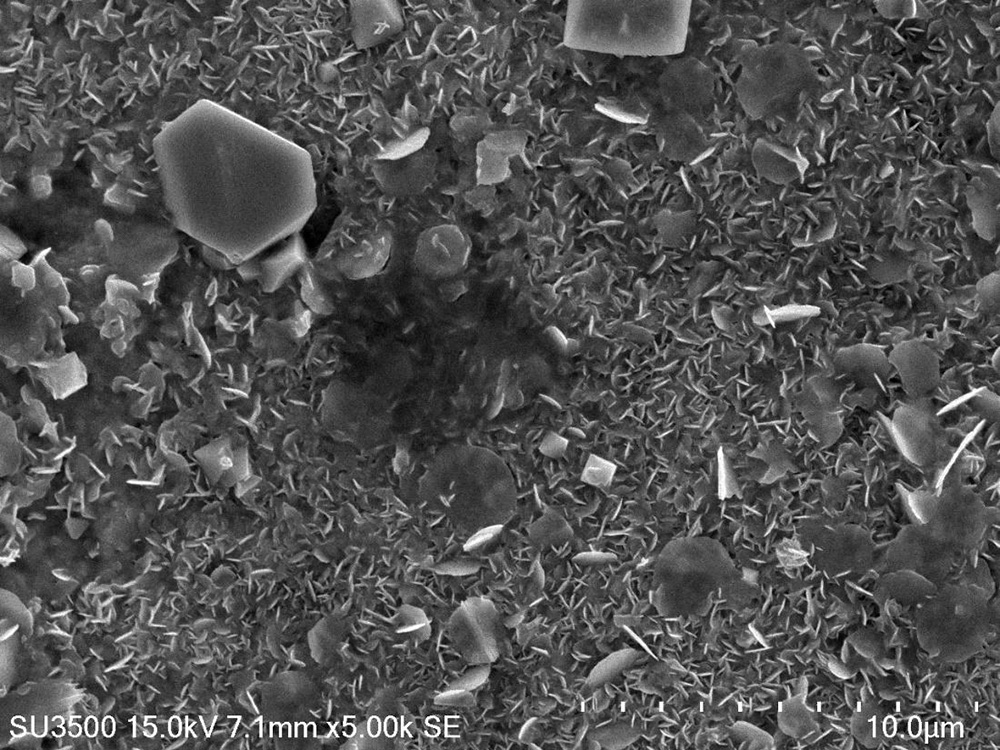

[0051] Embodiment 1: 10 parts of sodium carbonate, 1 part of sodium lauryl sulfonate, 2 parts of OP-10 emulsifier, the degreasing effect is as attached to the instruction manual figure 2 shown;

Embodiment 2

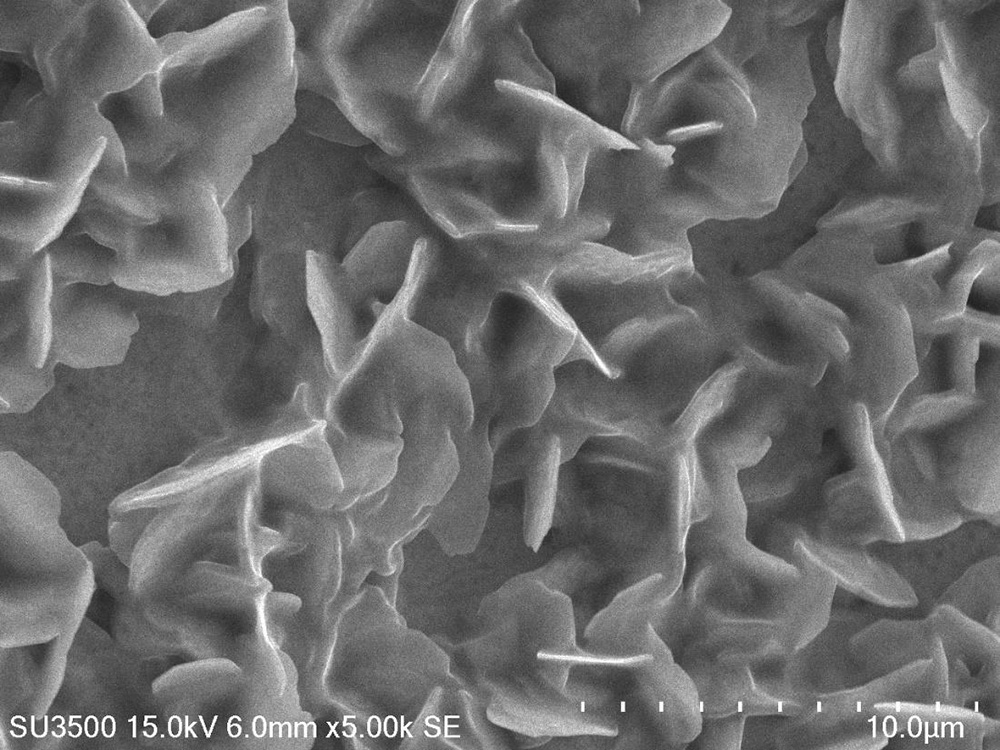

[0052] Embodiment two: 30 parts of sodium carbonate, 5 parts of sodium lauryl sulfonate, 4 parts of OP-10 emulsifier, the degreasing effect is as attached to the description image 3 shown;

Embodiment 3

[0053] Embodiment three: 20 parts of sodium carbonate, 3 parts of sodium lauryl sulfonate, 3 parts of OP-10 emulsifier, the degreasing effect is as attached to the description Figure 4 Shown:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com