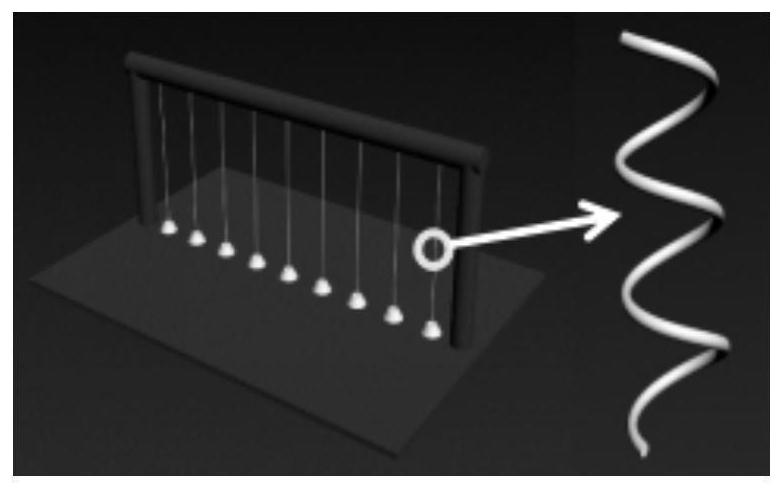

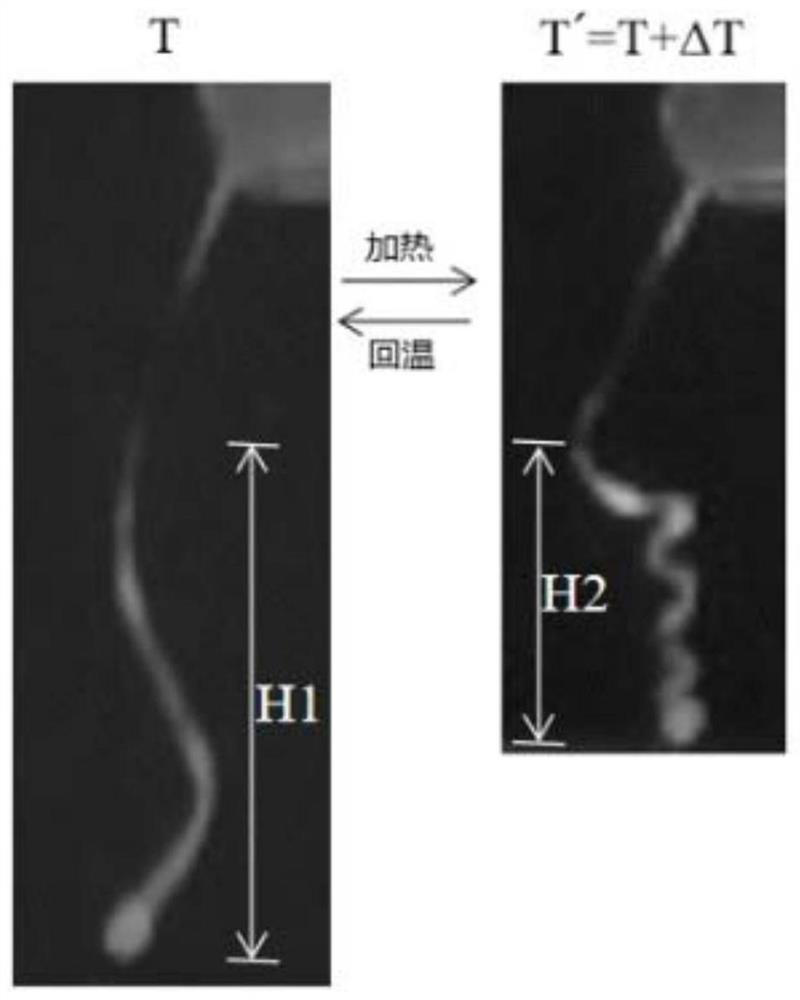

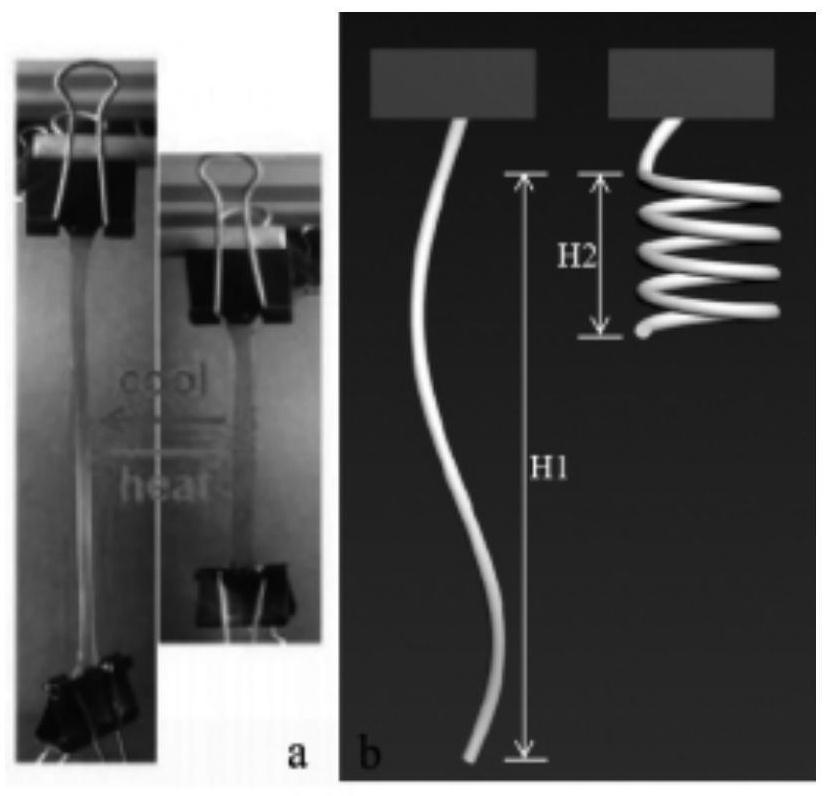

Liquid crystal elastomer fiber capable of being spirally bent and preparation method and application thereof

A technology of liquid crystal elastomers and liquid crystal monomers, applied in the direction of liquid crystal materials, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problem of single expansion and deformation, and achieve the effect of improving the deformation range and fiber performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the heat-responsive liquid crystal elastomer fiber provided according to the embodiment of the present invention includes the following steps:

[0031] (1) Add liquid crystal monomers HCM008, HCM009 and photoinitiator IR819 into the sample bottle, put a stirring bar and add an appropriate amount of dichloromethane to dissolve, stir until the system is transparent, add 2,2'-(1,2- Ethylenediyldioxo) diethanethiol, pentaerythritol tetra-3-mercapto propionate and dipropylamine; the mass parts of the raw materials used above are: liquid crystal monomer (HCM008, HCM009) 72.5-81.5 parts, mercaptan ( 2,2′-(1,2-Ethylenedioxy)diethanethiol, pentaerythritol tetra-3-mercaptopropionate) 17.0-26.4 parts, catalyst (dipropylamine) 0.6-1.2 parts, photoinitiator (IR819) 0.05-0.3 parts; keep stirring under room temperature and yellow light conditions to make the system undergo Michael addition reaction until the solvent dichloromethane is completely volatilized, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com