Heat preservation, decoration and maintenance integrated wallboard and wall body structure

A technology of thermal insulation board and wall board, applied in thermal insulation, wall, building components and other directions, can solve problems such as low efficiency, high cost, troublesome installation, etc., and achieve the effect of enhancing connection firmness and enhancing overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

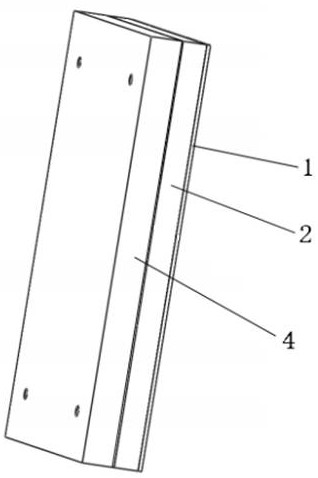

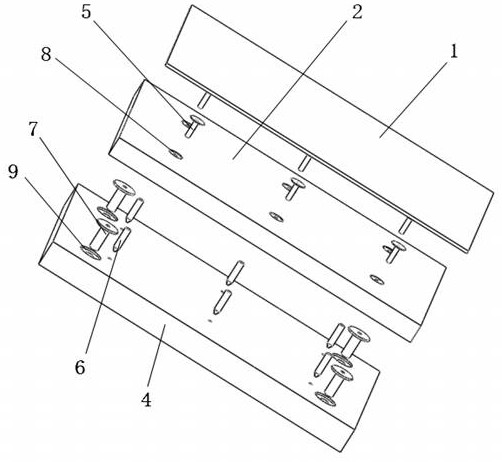

[0032] like Figure 1 to 3 As shown in this particular embodiment there is provided a heat integration maintenance decorative wall panels, comprising a lightweight aerated plate 4, insulation board 2, connected to the outer anchor member 7, the cap 5 is connected, the coupling head 6, lightweight aerated plate 2 and 4 between the insulation board with an adhesive binder as a whole, and the insulation board lightweight aerated plate 2 are connected by the connection between the anchor 4; inner connecting member comprises an anchor connected to the cap 5 and the connector 6, insulation board 2 is provided with an outer side surface of the first groove 8, the first groove 8 is provided with a first mounting through hole, the cap 5 is mounted is connected through a first mounting hole, the connecting head cap 5 is located in the first column recess 8, the shaft section connected to the cap 5 is located in the first mounting through hole, the head of the column connected to the cap 5 be...

specific Embodiment approach 2

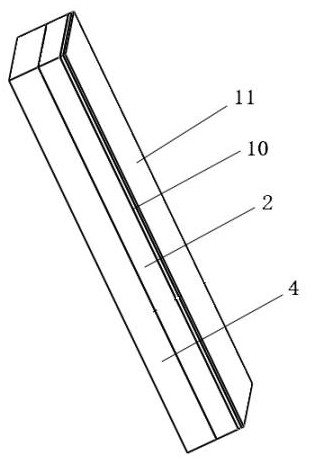

[0037] like Figure 4 As shown in this particular embodiment there is provided a wall structure including beams, columns, and in specific embodiments 1 integrated maintenance insulation decorative wall panels, integrated maintenance insulation decorative wall panels connected to the connecting member through the wall beams and columns, wall anchor connecting member connecting the outer connecting member 7, to maintain insulation decorative wall panels constitute an integrated part of the wall 100 is maintained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com