Method for detecting concentration of four acids in mixed acid liquor

A technology of mixing acid and acid concentration, which is applied in the field of detection and analysis, can solve the problems of complicated methods and inability to detect the components of acid liquid mixed with four kinds of acids, and achieves a simple operation method, which is conducive to product quality control and fast detection speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] To prepare mixed acid:

[0081] Four acids (sulfuric acid, hydrofluoric acid, hydrochloric acid, fluosilicic acid)

[0082] Preparation of standard solution: Accurately weigh 4.9201g of 98.32% sulfuric acid, 4.8624g of 40.69% hydrofluoric acid, 12.5335g of 32.02% hydrochloric acid, 16.5495g of 36.0% fluosilicic acid, and 1.1826g of water to prepare about 12% sulfuric acid and 5% hydrogen 40g of standard acid solutions of hydrofluoric acid, 10% hydrochloric acid, and 15% fluosilicic acid.

[0083] Standard solution preparation h 2 SO 4

[0084] The sampling in the following examples is all taken from Example 1.

Embodiment 2

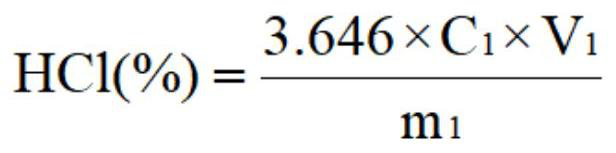

[0086] (1) Determination of total acidity and fluosilicic acid content

[0087] Take a sample of 1.0702g of the test solution into the titration bottle 1, and add 50ml of frozen KNO to the titration bottle 3 solution, add 0.1ml phenolphthalein indicator solution and keep the solution ice-cold (about 0°C). Use a 50mL automatic burette (with 0.4985mol / L standard NaOH titration solution inside) to titrate until the light pink color in the solution remains unchanged for 15 seconds, and consume 20.43ml of NaOH standard solution. The phenolphthalein indicator solution used at this time can be replaced by a mixed indicator of "bromothymol blue sodium salt + phenol red sodium salt". At this time, the titration end point is "deep purple without fading for 15 seconds".

[0088] Add 100mL of boiling water (referring to 99°C) to titration bottle 1, and immediately titrate with sodium hydroxide standard solution until the light pink color that appears remains unchanged for 15 seconds, and...

Embodiment 3

[0124] (1) Determination of total acidity and fluosilicic acid content

[0125] Take a sample of 1.0760g of the test solution into the titration bottle 1, and add 50ml of frozen KNO to the titration bottle 3 solution, add 0.1ml phenolphthalein indicator solution and keep the solution ice-cold (about 0°C). Use a 50mL automatic burette (with 0.4985mol / L standard NaOH titration solution inside) to titrate until the light pink color in the solution remains unchanged for 15 seconds as the end point, and consume 20.55ml of NaOH standard solution.

[0126] Add 100mL of boiling water to titration bottle 1, and immediately titrate with sodium hydroxide standard solution until the light pink color appears and remains unchanged for 15 seconds, and consumes 9.74ml of NaOH standard solution.

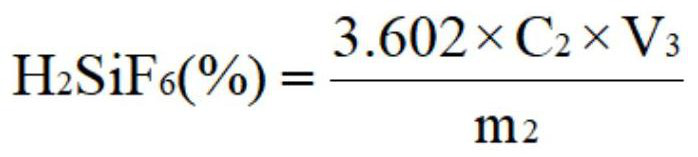

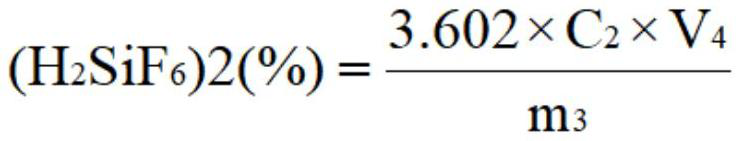

[0127] Use the following calculation formula to calculate the total acidity and fluosilicic acid content:

[0128]

[0129]

[0130] (2) Determination of hydrochloric acid content

[0131] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com