Vanadium carbide modified hard carbon material as well as preparation method and application thereof

A vanadium carbide and hard carbon technology, applied in electrochemical generators, active material electrodes, structural parts, etc., can solve the problems of limiting the practical application of sodium-ion batteries, low tap density, low volume energy density, etc. The effect of chemical properties, low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add vanadium pentoxide and oxalic acid into the aqueous solution at a molar ratio of 1:3, heat and stir at 80°C for 4 hours, and prepare a 0.3mol / L vanadium oxalate solution.

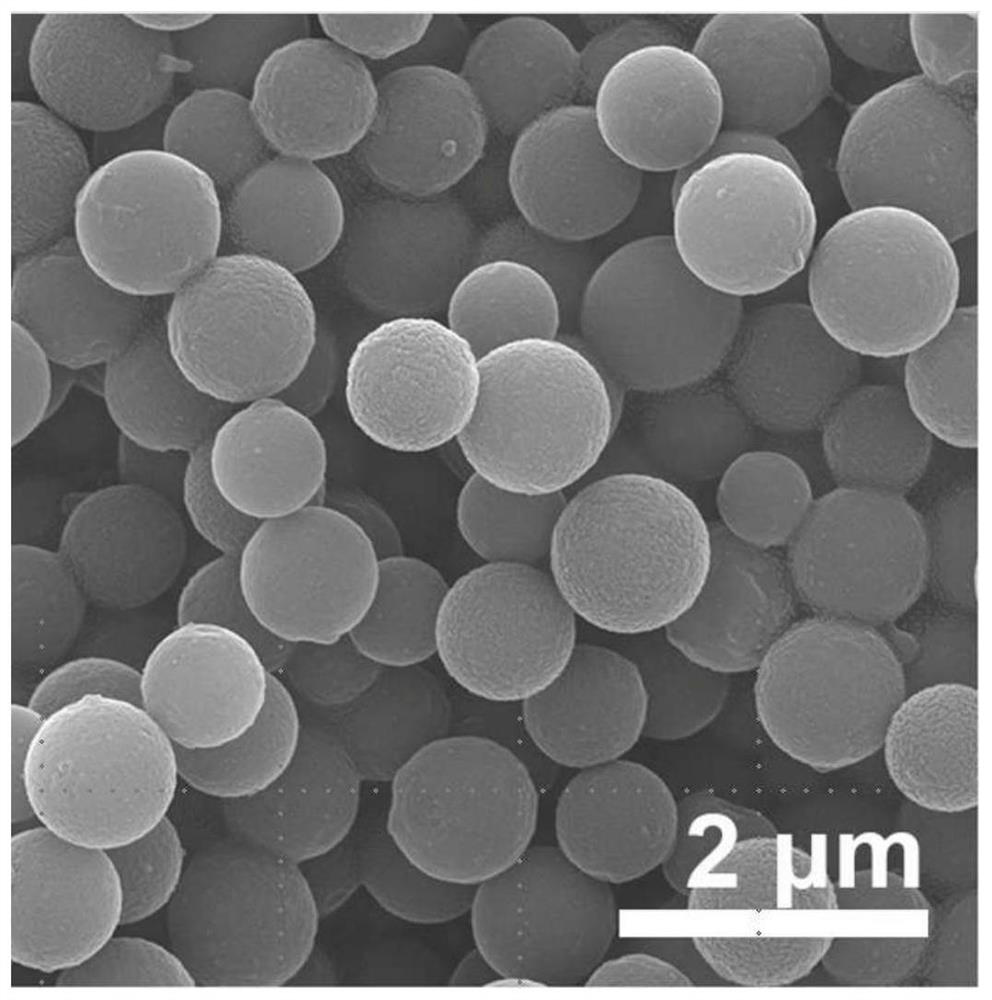

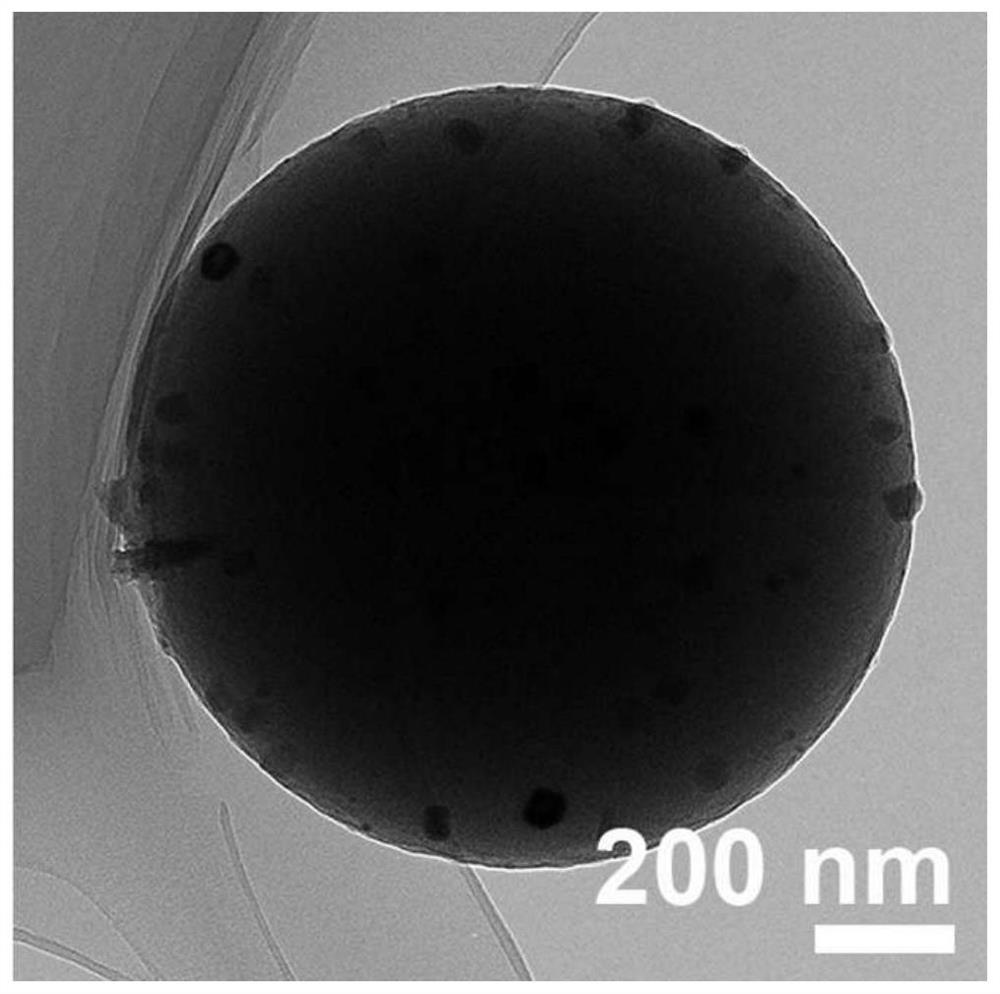

[0041] 1) Add 70mL 0.5mol / L glucose solution and 0.5mL vanadium oxalate solution into a 100mL reaction kettle and stir evenly, then put the reaction kettle into the furnace and heat it at 180°C for 12h, take it out after cooling, and use the obtained product deionized water and ethanol, and dried in an oven.

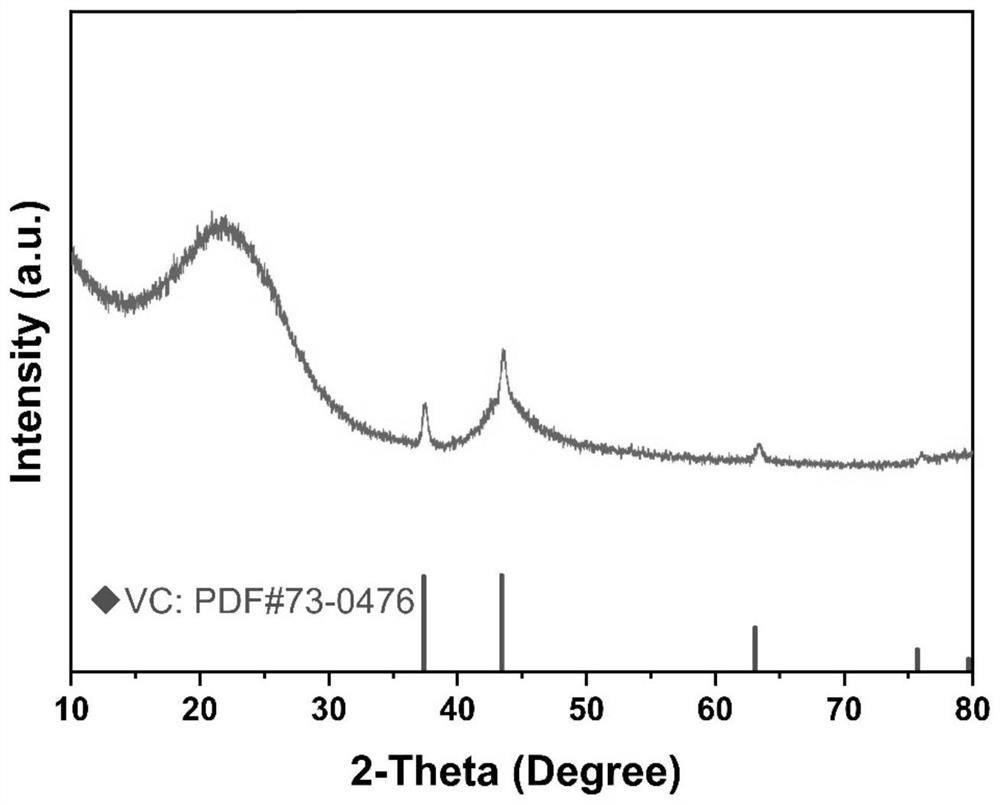

[0042] 2) Carbonize the above product in a protective atmosphere, raise the temperature to 1000°C at a heating rate of 10°C / min, then raise the temperature to 1300°C at a heating rate of 5°C / min, and keep it for 2 hours to obtain a vanadium carbide modified hard carbon composite energy storage Material.

[0043] 3) The obtained vanadium carbide-modified hard carbon composite energy storage material was prepared as a negative electrode for a sodium-ion battery, and electrochemical tests wer...

Embodiment 2

[0046] Add vanadium pentoxide and oxalic acid into the aqueous solution at a molar ratio of 1:3, heat and stir at 80°C for 4 hours, and prepare a 0.3mol / L vanadium oxalate solution.

[0047] 1) Add 70mL 2mol / L glucose solution and 2mL vanadium oxalate solution into a 100mL reaction kettle and stir evenly, then put the reaction kettle into the furnace and heat it at 160°C for 12h, take it out after cooling, and wash the obtained product with deionized water Wash with ethanol and dry in an oven.

[0048] 2) Carbonize the above product in a protective atmosphere, raise the temperature to 1000°C at a heating rate of 10°C / min, then raise the temperature to 1500°C at a heating rate of 5°C / min, and keep it for 2 hours to obtain a vanadium carbide modified hard carbon composite energy storage Material.

[0049] 3) The obtained vanadium carbide-modified hard carbon composite energy storage material was prepared as a negative electrode for a sodium-ion battery, and electrochemical test...

Embodiment 3

[0051] Add vanadium pentoxide and oxalic acid into the aqueous solution at a molar ratio of 1:3, heat and stir at 80°C for 4 hours, and prepare a 0.3mol / L vanadium oxalate solution.

[0052] 1) Add 70mL 0.125mol / L sucrose solution and 0.5mL vanadium oxalate solution into a 100mL reaction kettle and stir evenly, then put the reaction kettle into the furnace and heat it at 200°C for 12h, take it out after cooling, and use the obtained product deionized water and ethanol, and dried in an oven.

[0053] 2) Carbonize the above product in a protective atmosphere, raise the temperature to 1000°C at a heating rate of 10°C / min, then raise the temperature to 1800°C at a heating rate of 5°C / min, and keep it for 2 hours to obtain a vanadium carbide modified hard carbon composite energy storage Material.

[0054] 3) The obtained vanadium carbide modified hard carbon composite energy storage material is prepared as a negative electrode for a sodium ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com