Preparation method of low-mineralization micelle-state casein

A casein and casein glue technology, applied in animal protein processing, protein food ingredients, milk protein ingredients, etc., can solve the problems of difficult to accurately control the decalcification rate, exploration of conditions and cumbersome overall treatment process, etc. The effect of small binding state and protein properties, high practical application value, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation process of non-decalcified micellar casein

[0039] Take fresh milk for disc centrifugal degreasing treatment (fat content is 0.09%), and then use 1.4μm pore size ceramic membrane for sterilization treatment to obtain sterilized skim milk, and then use 100nm microfiltration ceramic membrane to separate casein micelles from the sample , the concentration factor is 5 times, and then supplemented with deionized water for 3 times of diafiltration to reduce the residue of impurities such as whey protein and improve the purity of casein. micelles.

Embodiment 2

[0040] Embodiment 2 high decalcification casein preparation technology

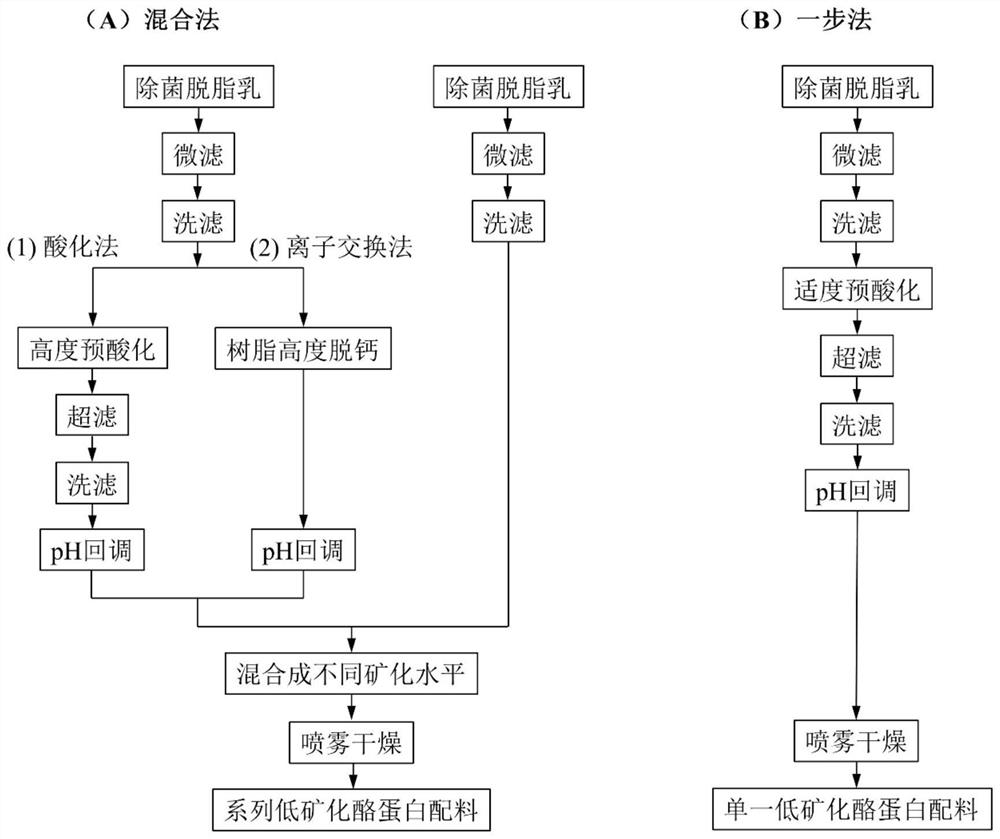

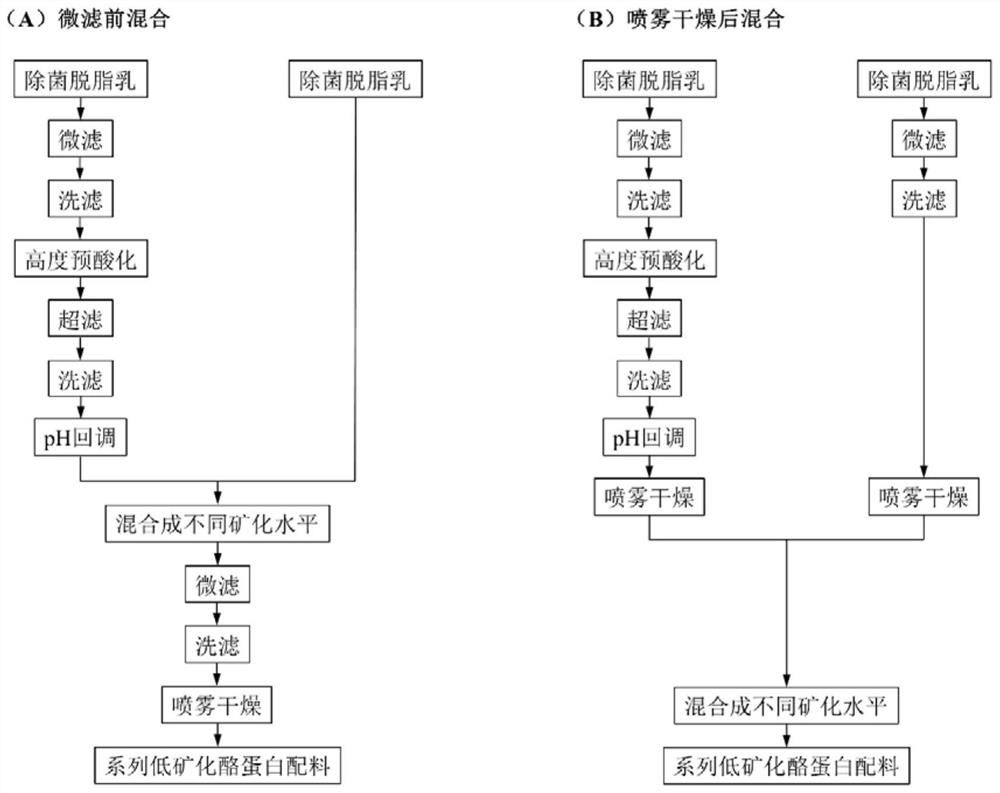

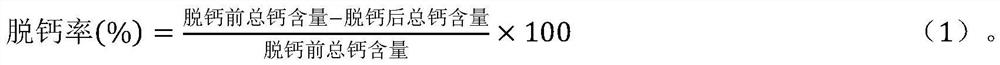

[0041] The main process such as figure 1 -As shown in -A, at first adopt 100nm microfiltration ceramic membrane to separate the casein micelles in the sterilized skim milk (same as Example 1), the concentration factor adopted is 5 times, then add deionized water and carry out diafiltration for 3 times, the temperature Control at 60°C to obtain undecalcified casein micelles. Then the acidification method or ion exchange method can be used to prepare high calcium-depleted casein, and the specific steps are as follows:

[0042] 1. Acidification method: Add 4 times the volume of deionized water to the separated non-decalcified casein micelles, and then add 35mM glucosinolate-δ-lactone to adjust the pH to 5.3. Then, an ultrafiltration membrane with a pore size of 10 kDa was used for ultrafiltration and diafiltration, the concentration factor was 5 times, the number of diafiltration was 3 times, and the treat...

Embodiment 3

[0044] Embodiment 3 one-step low mineralization micellar state casein preparation technology

[0045] The traditional one-step process for preparing low-mineralized casein is as follows: figure 1 As shown in -B, the non-decalcified casein micelles obtained in Example 1 were supplemented with 4 times the volume of deionized water, and then 12 mM glucosinolate-δ-lactone was added to adjust the pH value to 6.2. Afterwards, an ultrafiltration membrane with a pore size of 10 kDa was used for ultrafiltration and diafiltration. The concentration factor was 5 times, and the number of diafiltration was 3 times. The treatment temperature was controlled at 60 ° C, and then the pH was adjusted back to the initial value. Spray drying was carried out after the condition of 25°C was maintained for 60 minutes, and the inlet temperature and outlet temperature were 190°C and 90°C, respectively. Known through measuring, the decalcification rate at this moment is 28%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com