Monatomic rhodium catalyst as well as preparation method and application thereof

A rhodium catalyst and catalyst technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve restrictions on industrial production, cumbersome synthesis steps, long synthesis time, etc. problems, to achieve the effect of low production equipment requirements, simple process, stable chemical properties and physical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of monoatomic rhodium catalyst:

[0033] Weigh 0.5g rutile titanium dioxide powder, 4.12mg RhCl 3 ·3H 2 0, 2mL of ultra-pure water was added to a round-bottom evaporating dish, stirred and sonicated for 10 minutes to make it evenly mixed, then continuously stirred under the condition of heating in a water bath to evaporate the water to obtain a pink solid powder, and the pink solid powder was placed in a mortar Grind for about 30 minutes to make it further mixed evenly, then transfer it to a crucible, put it into a muffle furnace for calcination at 700°C for 8 hours, and then grind the product for 30 minutes to obtain monoatomic rhodium Ti after cooling to room temperature. 0.9975 Rh 0.0025 o 2 catalyst.

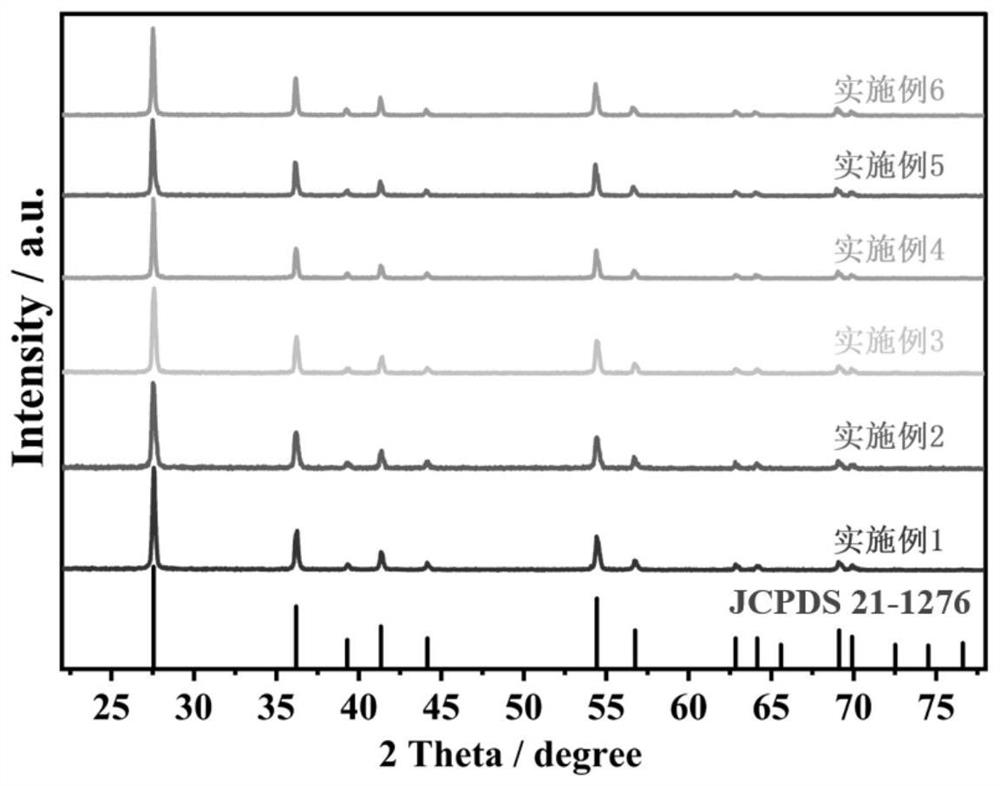

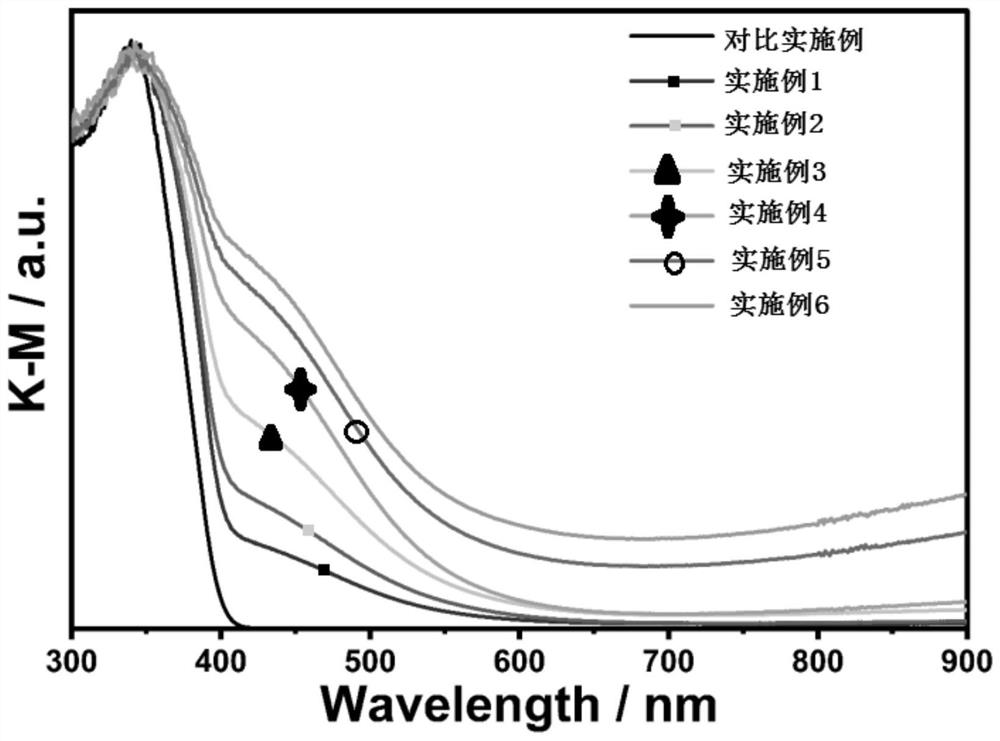

[0034] Ti 0.9975 Rh 0.0025 o 2 The X-ray diffraction pattern (XRD) of the catalyst at 700°C is shown in figure 1 , UV-Vis DRS (UV-Vis DRS) see figure 2 . Spherically aberration-corrected High Angle Annular Dark Field Scanning Tr...

Embodiment 2

[0036] A kind of preparation method of monoatomic rhodium catalyst:

[0037] Weigh 0.5g rutile titanium dioxide powder, 8.28mg RhCl 3 ·3H 2 0, 2mL of ultra-pure water was added to a round-bottom evaporating dish, stirred and sonicated for 10 minutes to make it evenly mixed, then continuously stirred under the condition of heating in a water bath to evaporate the water to obtain a pink solid powder, and the pink solid powder was placed in a mortar Grind for about 30 minutes to make it further mixed evenly, then transfer it to a crucible, put it in a muffle furnace for calcination at 700°C for 8 hours, and then grind the product for 30 minutes to obtain a monoatomic rhodium catalyst, which is marked as Ti 0.995 Rh 0.005 o 2 / 700°C.

[0038] Ti 0.995 Rh 0.005 o 2 The X-ray diffraction pattern (XRD) of the catalyst at 700°C is shown in figure 1 , UV-Vis DRS (UV-Vis DRS) see figure 2 . Spherically aberration-corrected High Angle Annular Dark Field Scanning Transmission E...

Embodiment 3

[0040] A kind of preparation method of monoatomic rhodium catalyst:

[0041] Weigh 0.5g rutile titanium dioxide powder, 16.65mg RhCl 3 ·3H 20, 2mL of ultra-pure water was added to a round-bottom evaporating dish, stirred and sonicated for 10 minutes to make it evenly mixed, then continuously stirred under the condition of heating in a water bath to evaporate the water to obtain a pink solid powder, and the pink solid powder was placed in a mortar Grind for about 30 minutes to make it further mixed evenly, then transfer it to a crucible, put it in a muffle furnace for calcination at 700°C for 8 hours, and then grind the product for 30 minutes to obtain a monoatomic rhodium catalyst, which is marked as Ti 0.99 Rh 0.01 o 2 / 700°C.

[0042] Ti 0.99 Rh 0.01 o 2 The X-ray diffraction pattern (XRD) of the catalyst at 700°C is shown in figure 1 , UV-Vis DRS (UV-Vis DRS) see figure 2 . Depend on figure 1 Visible, Ti 0.99 Rh 0.01 o 2 The positions of all the diffraction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com