Kiln for producing high-quality photovoltaic glass and novel calendering forming overflow opening

A calendering and photovoltaic glass technology, which is applied in glass furnace equipment, furnace types, glass production, etc., can solve the problems of high glass edge loss rate at the forming part, uneven glass thickness, and high intermediate temperature, so as to facilitate calendering and forming control , the effect of reducing glass bubble defects and reducing the temperature difference of glass liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to solve the defects pointed out in the background art, the present invention is specially applied for. The present application will now be described more fully with reference to the accompanying drawings, in which example embodiments are shown. However, the invention should not be construed as limited to the embodiments set forth herein. The disclosed features of the example embodiments may be combined as is readily understood by a person skilled in the art to which this application pertains. Well-known functions or constructions are not described in detail in this application for brevity or clarity.

[0050] The application is described in detail below in conjunction with accompanying drawing:

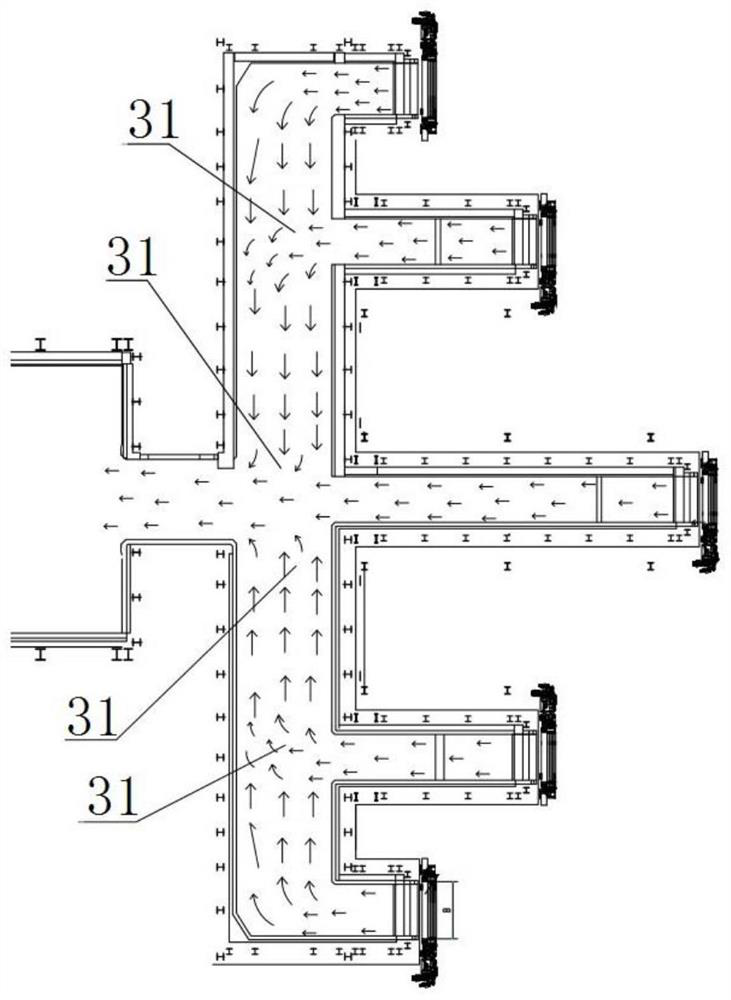

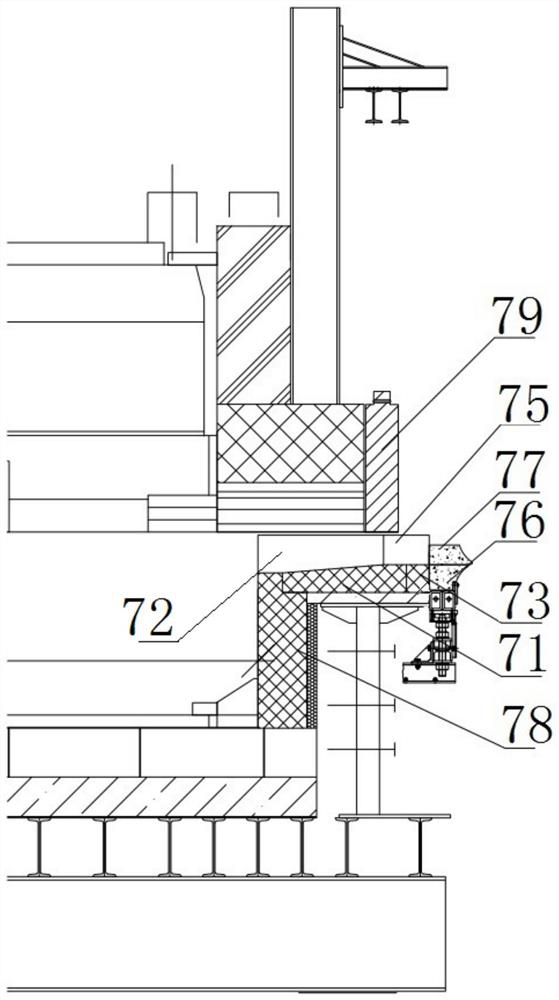

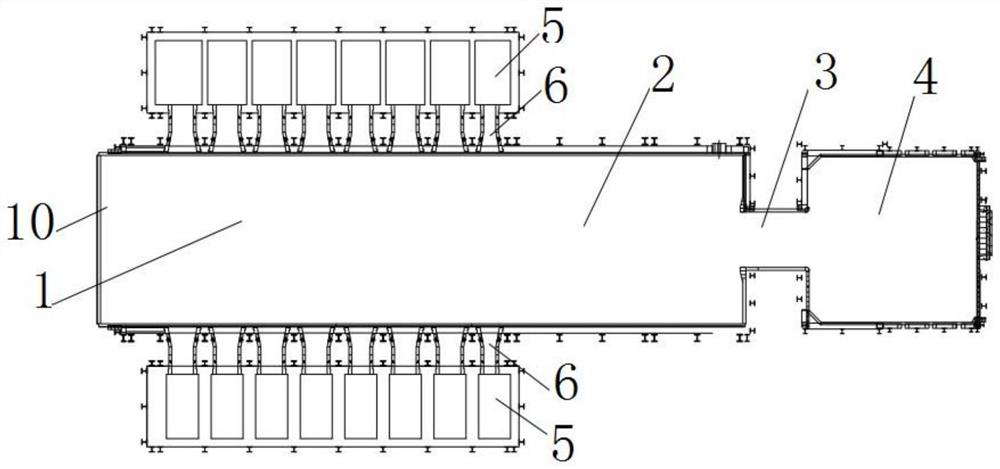

[0051] like image 3 , Figure 4 As shown, the embodiment of the present invention provides an ultra-large-tonnage ultra-clear glass furnace for producing high-quality photovoltaic glass, with a daily melting capacity of more than 1,100 tons. It includes a meltin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com