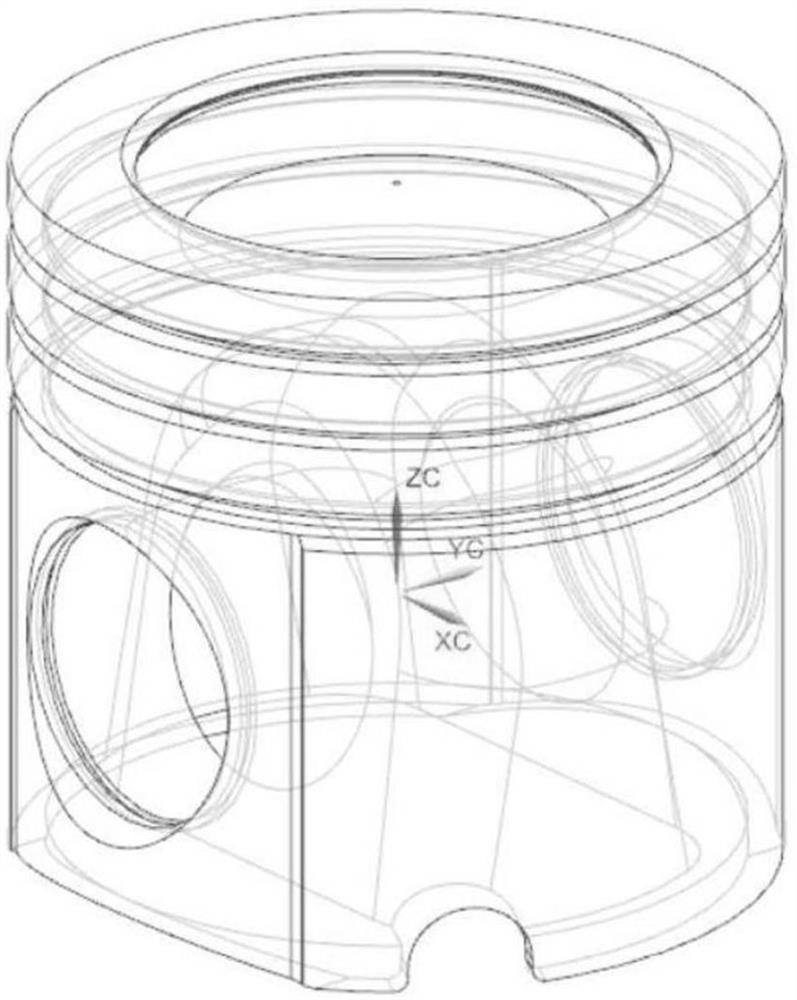

Carbon nanotube modified composite material piston for engine as well as preparation method and application of carbon nanotube modified composite material piston

A technology of carbon nanotube modification and composite materials, which is applied in the direction of engine components, machines/engines, pistons, etc., can solve problems such as unsatisfactory engines, achieve improved interface bonding, improve fuel efficiency and engine power, and good self-lubrication sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) In the axial direction, 12K T700 carbon fiber non-weft cloth is combined with a layer of carbon fiber mesh needle punching to form a unit layer, and in the circumferential direction, 12K T700 carbon fiber is continuously wound and compounded with a layer of carbon fiber mesh needle punching to form another unit layer. Layers and unit layers are alternately superimposed and continuously needled to produce a density of 0.40g / cm 3 Carbon fiber prefabricated body (ie piston prefabricated body);

[0035] (2) Heat-treat the carbon fiber preform at 2100°C for 1 hour under a helium protective atmosphere;

[0036] (3) Using a mixture of natural gas and propane as the carbon source gas to prepare a carbon dioxide gas with a density of 1.35g / cm 3The C / C porous body, in which the volume ratio of natural gas:propane:nitrogen is 4:1:6, the infiltration time is 300h, the residence time is 1.8s, the infiltration temperature is 1030℃, and the pressure is 2000Pa;

[0037] (4) heat-...

Embodiment 2

[0044] (1) Needle punching with 12K T800 carbon fiber non-weft cloth combined with a layer of carbon fiber mesh tire in the axial direction, continuous winding with 12K T1000 carbon fiber combined with a layer of carbon fiber mesh tire needle punching in the circumferential direction, unit layer and unit layer alternate superimposed continuous needle punching , to prepare a density of 0.55g / cm 3 Carbon fiber preform;

[0045] (2) Heat-treat the carbon fiber preform at 2000°C for 0.5h under an argon protective atmosphere;

[0046] (3) Using a mixture of propane and nitrogen as the gas source to prepare a density of 1.35g / cm 3 The C / C porous body, in which the volume ratio of propane to nitrogen is 1:8, the infiltration time is 500h, the residence time is 2.0s, the infiltration temperature is 1050℃, and the pressure is 2500Pa;

[0047] (4) heat-treat the C / C porous body at a temperature of 2250°C, a pressure of 1500Pa, and a helium atmosphere for 2 hours;

[0048] (5) Machini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com