Preparation method and application of konjak gel powder

A gel powder, konjac technology, applied in the application, the function of food ingredients, oligosaccharide-containing food ingredients, etc., can solve problems such as restricting the development of konjac industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

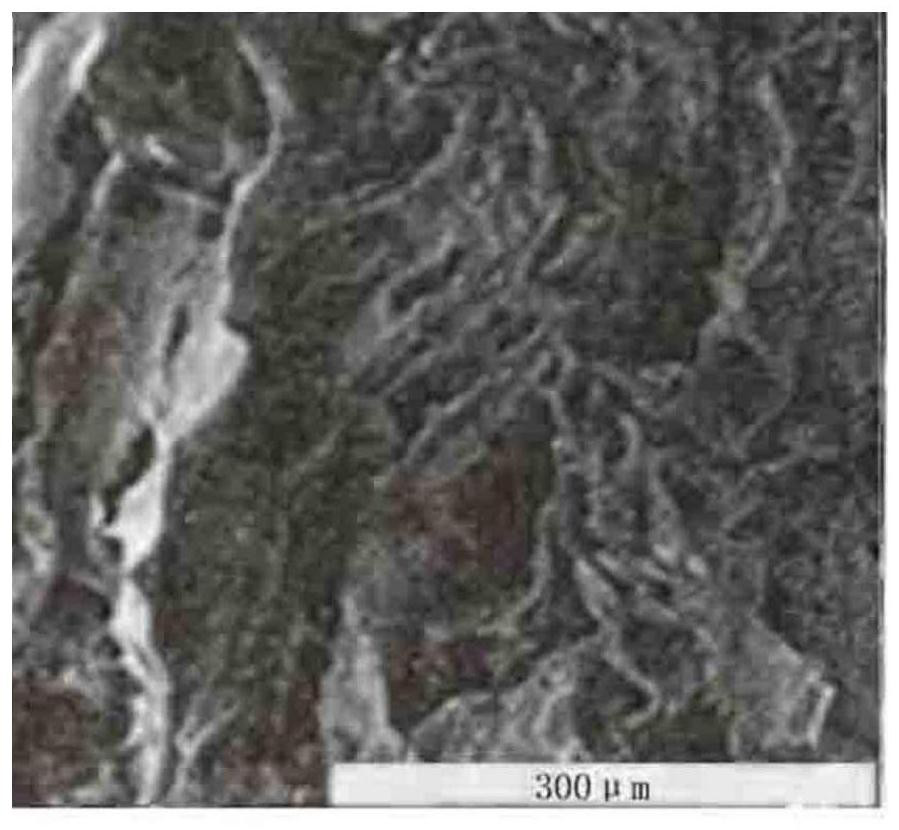

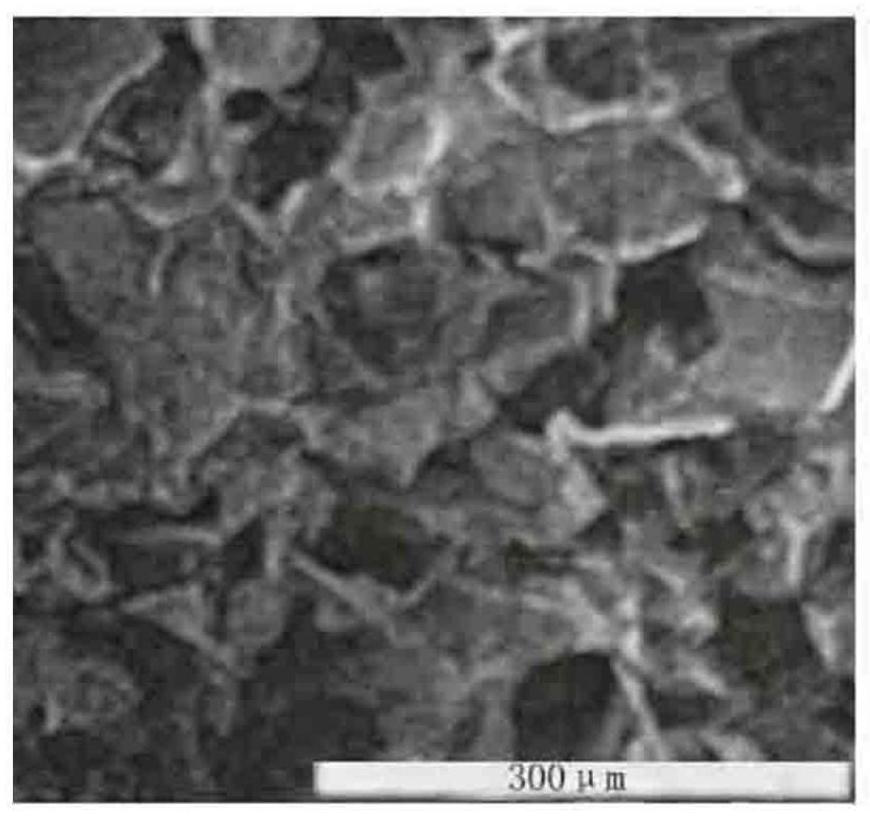

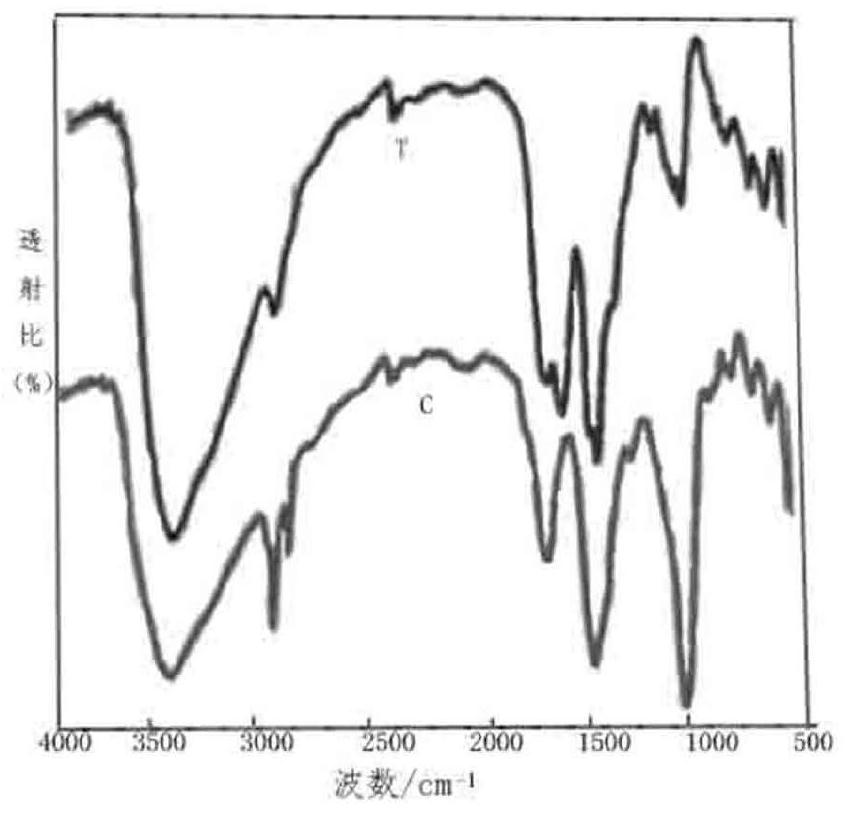

Image

Examples

Embodiment 1

[0070] The preparation method of the konjac jelly powder of the present embodiment may further comprise the steps:

[0071] Step 1: Weigh the raw materials in the following mass percentages: 2.5% konjac fine powder, 0.03% alkali, 0.1% agar powder, 0.45% microcrystalline cellulose, 0.5% glycerin, 0.5% absolute ethanol and 95.92% water;

[0072] Step 2: Stir and mix the raw materials weighed in step 1, place them at room temperature for 8 hours, and heat and solidify them by steaming at 80°C for 2 hours. Cut the solidified material into pieces, put it into clean water, and soak until it is colorless or transparent. Add 4 times the weight of clean water at 92°C to the cut and rinsed material, and cook for 25 minutes. Dry at 80°C for 14 hours; then crush and pass through a 40-mesh sieve to obtain konjac gel powder.

Embodiment 2

[0074] The preparation method of the konjac jelly powder of the present embodiment may further comprise the steps:

[0075] Step 1: Weigh the raw materials in the following mass percentages respectively: 4.0% konjac flour, 0.2% sodium bicarbonate, 1.2% fructooligosaccharide, 0.8% hydroxypropyl cellulose, 5.0% glycerin, 9.6% 52% edible liquor and 79.2% water %

[0076] Step 2: Stir and mix the raw materials weighed in step 1, place them at room temperature for 12 hours, and heat and solidify them by steaming at 110°C for 1 hour. Cut the solidified material into pieces, put it into clean water, and soak until it is colorless or transparent. Add 3 times the weight of clean water at 90°C to the cut and rinsed material, and cook for 30 minutes. Dry at 50°C for 36 hours; then crush and pass through an 80-mesh sieve to obtain konjac gel powder.

Embodiment 3

[0078] The preparation method of the konjac jelly powder of the present embodiment may further comprise the steps:

[0079] Step 1: take the raw materials of following mass percentage respectively: konjac powder 3.2%, sodium bicarbonate 0.05%, sodium carbonate 0.05%, sodium carboxymethyl cellulose 0.6%, methyl cellulose 0.5%, glycerin 2.5%, no Water ethanol 2.5% and water 90.6%;

[0080] Step 2: Stir and mix the raw materials weighed in step 1, place them at room temperature for 24 hours, heat and solidify them by boiling in water, the temperature is 100°C, and the time is 1.5 hours. Cut the solidified material into pieces, put it into clean water, and soak until it is colorless or transparent. Add 3-5 times the weight of clean water at 96°C to the cut and rinsed material, and cook for 25 minutes. Dry at 60°C for 30 hours; then crush and pass through an 80-mesh sieve to obtain konjac gel powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com