Perfluoroisobutyronitrile/carbon dioxide recovered insulating gas adsorption, purification and recycling method

A technology of perfluoroisobutyronitrile and carbon dioxide, applied in chemical instruments and methods, alkali metal oxides/hydroxides, separation methods, etc., can solve problems such as reducing recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of adsorbent: Weigh a certain amount of columnar activated carbon particles (diameter 2-3mm) as a carrier, mix with metal salt solution at a solid-liquid ratio of 1 / 3, wherein Cu(NO 3 ) 2 、KNO 3 , Ni(NO 3 ) 2 The concentrations are 0.1mol / L, 0.08mol / L, and 0.05mol / L, respectively, and stand at room temperature 25°C for 8h. Filtered and washed with deionized water until Cu-free 2+ Detected, transferred to 120 ℃ oven to dry for 12h. The dried adsorbent was filled in a tubular electric furnace, fired with nitrogen gas at 250°C for 12 hours, and cooled to room temperature for use.

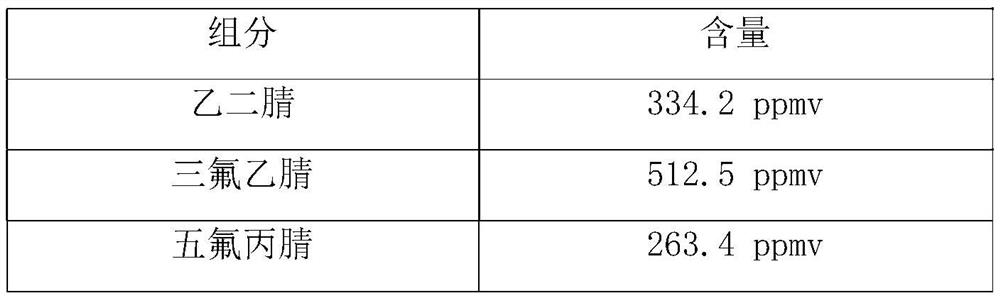

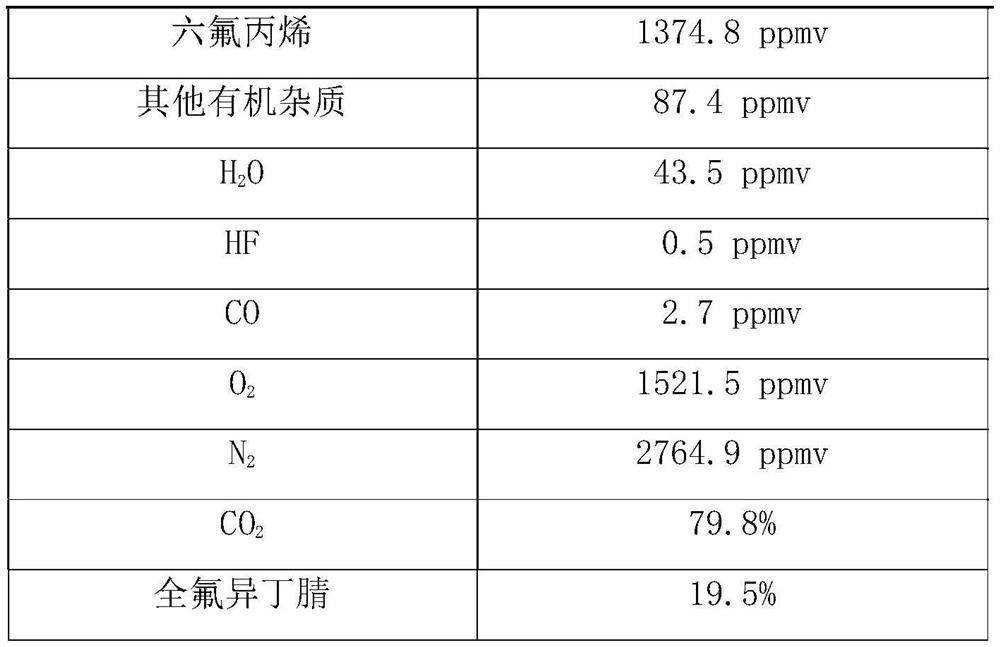

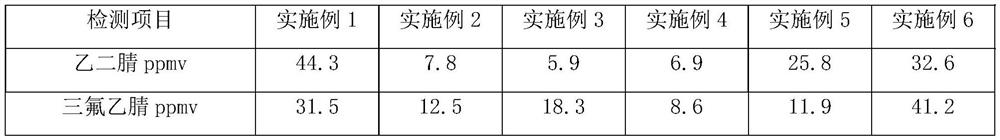

[0040] The application of the adsorbent: put the treated adsorbent into the gas-solid phase adsorption device, the filling volume is 200ml, at 25°C, 0.1MPa (absolute pressure), the recovery gas of perfluoroisobutyronitrile is introduced, and the space velocity is 500h -1 , the adsorption product was quantitatively analyzed for impurity content by GC-PDD, and the results are sho...

Embodiment 2

[0042] Preparation of adsorbent: Take a certain amount of 10X molecular sieve (diameter 3mm) as a carrier, mix it with metal salt solution at a solid-to-liquid ratio of 1 / 5, wherein Zn(NO 3 ) 2 、NaNO 3 , La(NO 3 ) 3 The concentrations are 0.15mol / L, 0.1mol / L, and 0.08mol / L, respectively, and stand at room temperature 45°C for 8h. Filtered and washed with deionized water to be free of Zn 2+ Detected, transferred to 150 ℃ oven to dry for 12h. The dried adsorbent was filled in a tubular electric furnace, fired with nitrogen gas at 350°C for 12 hours, and cooled to room temperature for use.

[0043] The application of the adsorbent: put the treated adsorbent into the gas-solid phase adsorption device, the filling volume is 200ml, at 25°C, 0.1MPa (absolute pressure), the recovery gas of perfluoroisobutyronitrile is introduced, and the space velocity is 500h -1 , the product after adsorption was quantitatively analyzed for impurity content by GC-PDD, and the results are shown ...

Embodiment 3

[0045] Preparation of adsorbent: Weigh a certain amount of SBA-15 molecular sieve raw powder as a carrier, and mix it with a carbonate mixture of metal K, Mg, and Ce in a mass ratio of 1 / 0.5, where K 2 CO 3 / MgCO 3 / C 2 (CO 3 ) 3 =1 / 0.5 / 0.5 (mass ratio). A small amount of water was added as a binder, and a strip-shaped adsorbent with a diameter of 3 mm was prepared by using a extruder, and dried in an oven at 120°C for 8 hours. The dried adsorbent was packed in a tubular electric furnace, fired with nitrogen gas at 350 °C for 12 h, and cooled to room temperature for use.

[0046] The application of the adsorbent: put the treated adsorbent into the gas-solid phase adsorption device, the filling volume is 200ml, at 25°C, 0.1MPa (absolute pressure), the recovery gas of perfluoroisobutyronitrile is introduced, and the space velocity is 500h -1 , the product after adsorption was quantitatively analyzed for impurity content by GC-PDD, and the results are shown in Table 2. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com