Pulping system for flue gas desulfurization process

A flue gas and slurry tank technology, applied in gas treatment, chemical instruments and methods, mixers with rotating stirring devices, etc., can solve the problems of long feeding time, many equipments, and difficult feeding, and achieve convenient operation, Low energy consumption and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

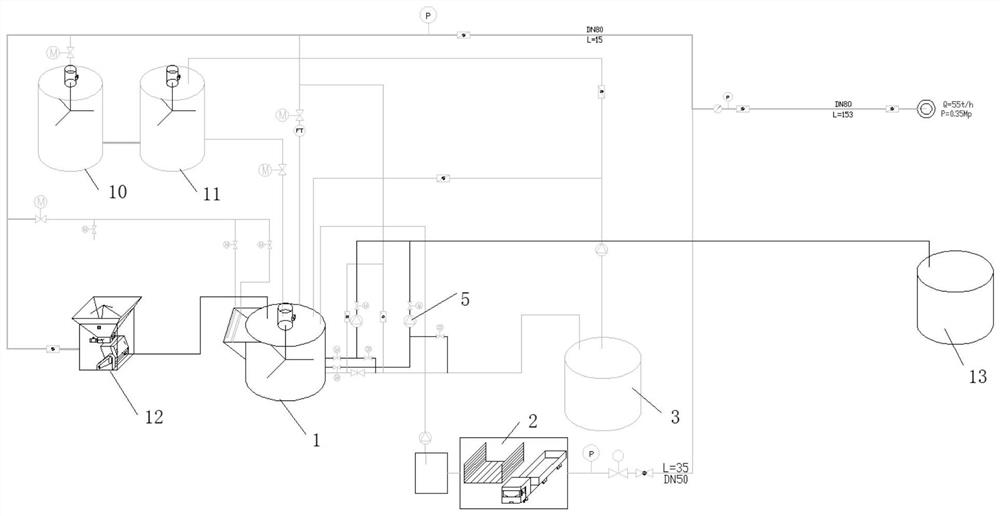

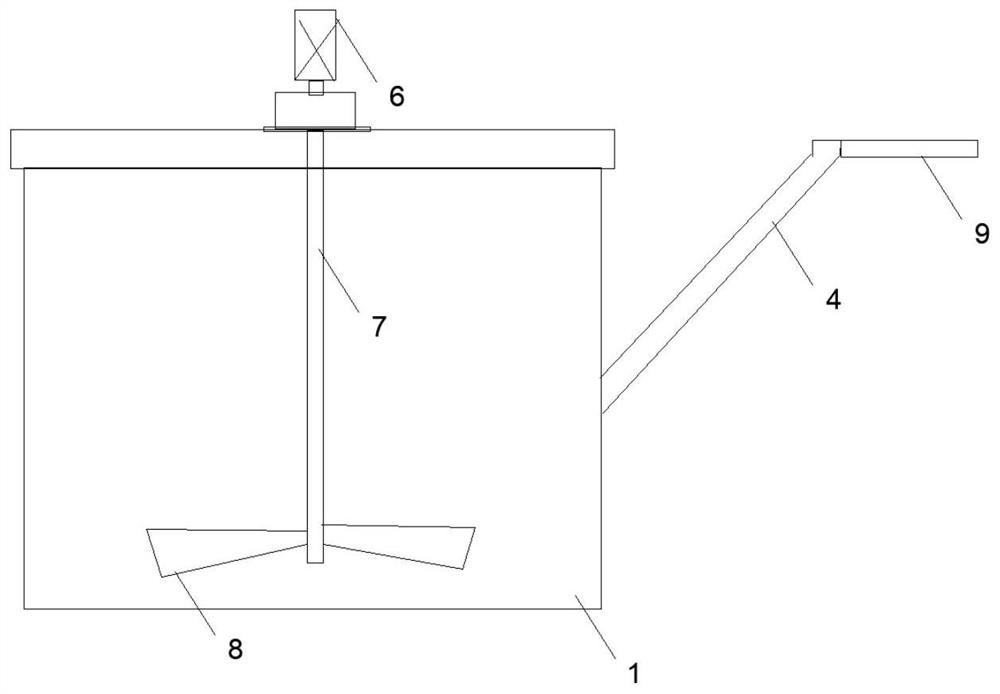

[0039] Such as Figure 1-2 As shown, a pulping system used in the flue gas desulfurization process includes a pulping tank 1, a car washing tank 2 and a sewage tank 3, the drain of the car washing tank 2 is connected to the pulping tank 1 through a pipeline, and the sewage The water outlet of the pool 3 is connected with the slurry tank 1 through a pipeline. The slurry tank 1 is used for slurry preparation, the car wash tank 2 is used for cleaning the vehicles when they leave the site, and the sewage tank 3 collects waste water and discharges it to the slurry tank 1 for recycling.

[0040] The water inlet of the slurry tank 1 is connected with a water storage tank through a pipeline, a discharge slope 4 is provided at the feed port on one side of the slurry tank, a stirring device is arranged in the slurry tank, and a stirring device is arranged in the slurry tank. A slurry delivery pump 5 is arranged at the bottom, and the liquid outlet of the slurry delivery pump 5 is conne...

Embodiment 2

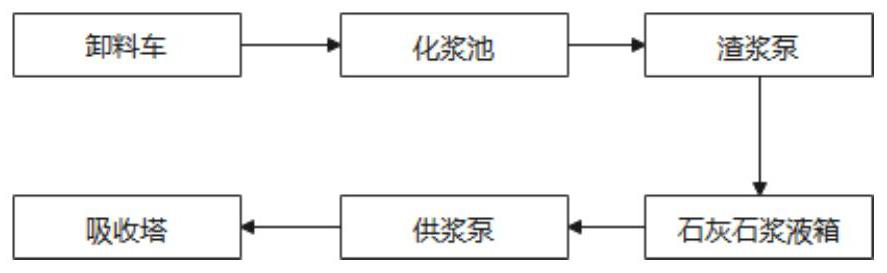

[0051] The working process of a pulping system for the flue gas desulfurization process described in Example 1 is as follows:

[0052] The new desulfurizer is transported to the slurry tank by belt truck (or transported to the storage yard, and added to the slurry tank by a forklift), and the slurry tank is replenished in advance. The ratio of water to material is 2:1, specifically 2 tons of water For 1 ton of new desulfurizer, the density of the slurry prepared according to this ratio is basically maintained at 1150kg / m 3 , until the slurry tank is full, after being uniformly stirred by the stirring device, the new desulfurizer slurry is delivered to the slurry storage tank by the slurry delivery pump at the bottom of the slurry tank, and is transported to the interior of the absorption tower by the slurry supply pump, and is controlled by the flow adjustment of the slurry supply pump PH (5.2-5.8) of the absorption tower, or directly transport the slurry to the absorption tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com