Preparation method for raw bamboo filament/polypropylene/rubber plate/bamboo willow veneer building template

A construction formwork and rubber sheet technology, which is applied in the jointing of wooden veneers, flat products, manufacturing tools, etc., can solve the problems of unsuitable construction formwork processing methods and low bending strength, and achieve the reduction of mechanical strength and water absorption , Excellent effect of thickness expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

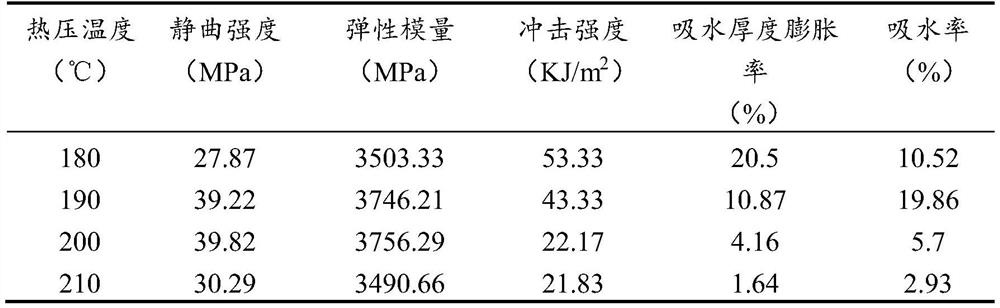

Examples

Embodiment Construction

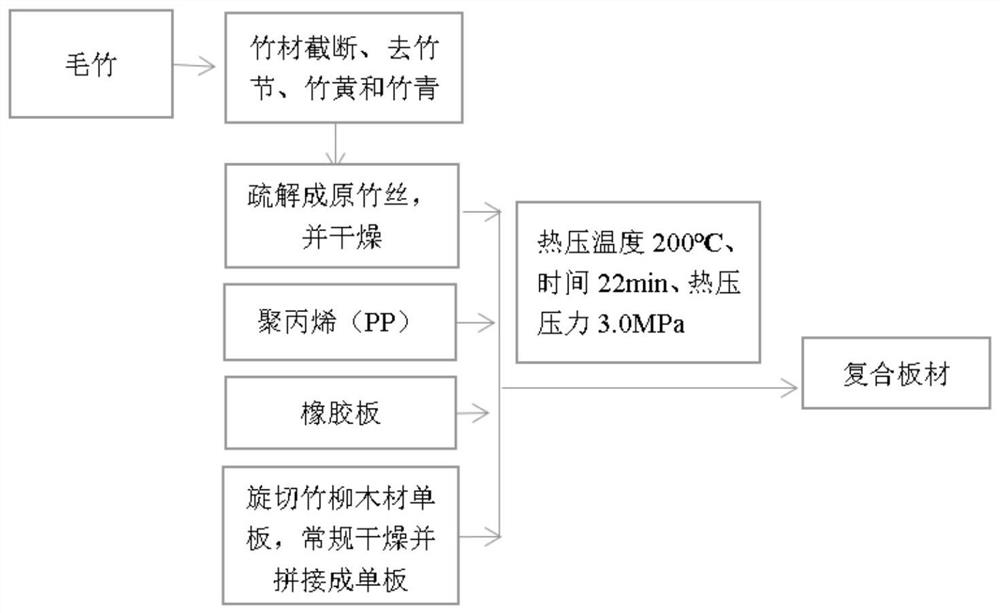

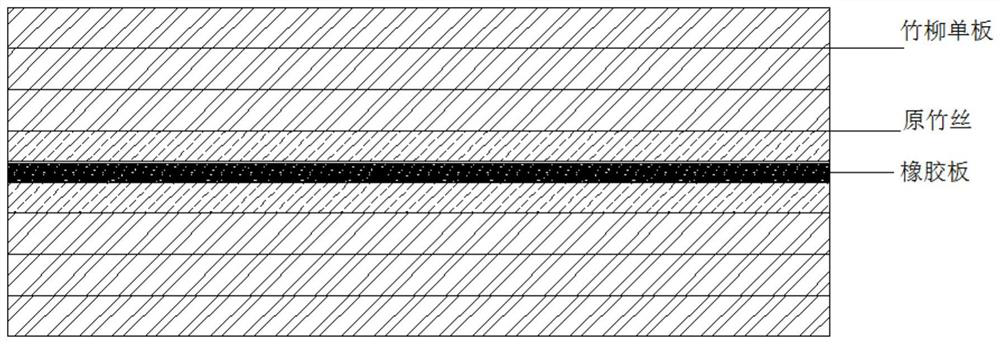

[0020] A kind of raw bamboo silk / polypropylene / rubber board / bamboo willow veneer building formwork preparation method

[0021] (1) Fresh or moso bamboo with a moisture content greater than 15% is cut into 2440mm long moso bamboo as required; through a device equipped with an inner milling cutter and an outer planer, the inner and outer nodes of the moso bamboo are removed simultaneously, and then processed into Bamboo strips are obtained by removing bamboo yellow and bamboo green to obtain raw bamboo.

[0022] (2) After the raw bamboo is subjected to high-temperature cooking treatment for 1 hour, it is decomposed, and the softened bamboo strips are decomposed into bamboo filaments of about 1 mm, and then dried to obtain the original bamboo filaments.

[0023] (3) Rotating bamboo willow wood with a diameter of 300mm and above into 1220mm wide veneers, and drying; and splicing the veneer tapes into 2440*1220mm plates to obtain bamboo willow veneers.

[0024] (4) Heat the polypr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com