Preparation method of perovskite material powder

A technology of perovskite materials and perovskite powders, which is applied in the preparation of amino compounds from amines, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., and can solve the problems of adapting to rapid mass industrial production, long-term heating or stirring , It is difficult to solve the problems of removing impurities, etc., to achieve the effect of facilitating mass industrial production, wide applicability, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

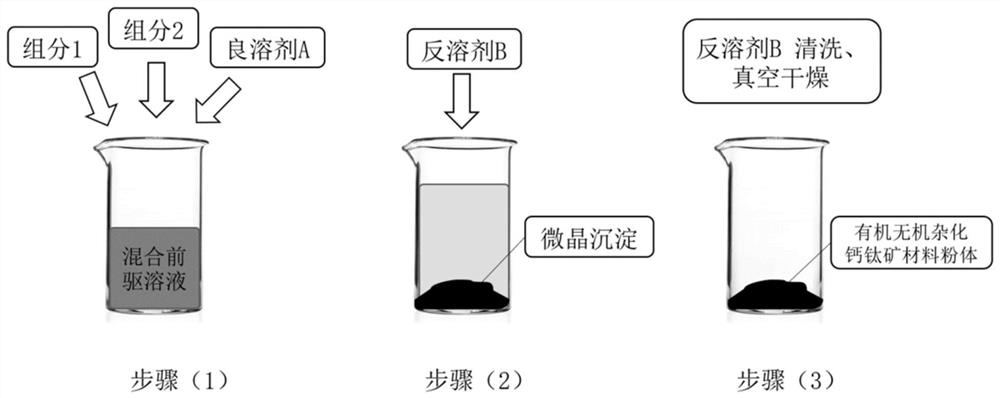

Method used

Image

Examples

Embodiment 1

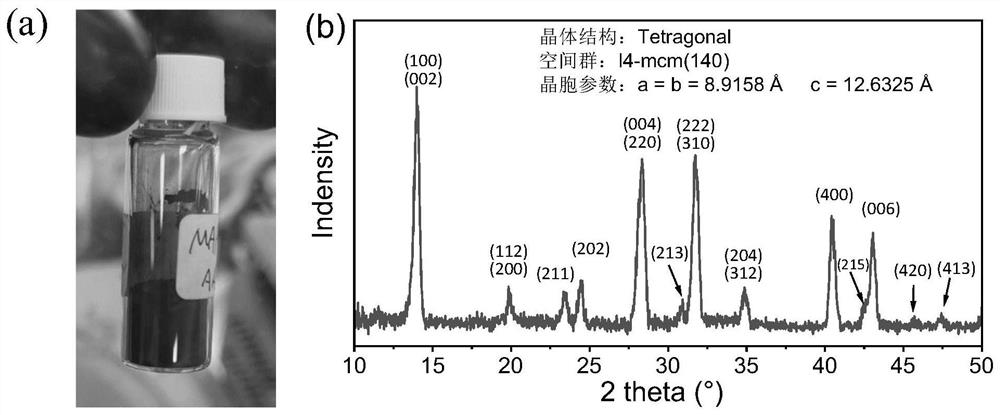

[0036] Low-purity raw material 1.5mmol MAI (methylamine hydroiodide, CH 3 NH 3 I, purity 98%) and 1.5mmol PbI 2 (lead iodide, purity 98%) was dissolved in 1 ml of ethylene glycol methyl ether solvent, and stirred continuously for 1 h to obtain a mixed solution, which was then filtered and transferred to a small beaker. Inject 2ml of ether into the beaker, stir for 30 seconds, and precipitate black perovskite crystallite precipitate MAPbI at the bottom of the beaker 3 . Precipitate MAPbI from the precipitated perovskite crystallites 3 Use ether to wash 3 times, and remove the residual ether by vacuum drying at room temperature to obtain the perovskite material powder MAPbI of this embodiment 3 , and the calculated yield was 93%.

[0037] The perovskite material powder MAPbI that the present embodiment makes 3 Photos and XRD diffraction patterns such as figure 2 shown. The XRD pattern shows that the perovskite material powder is a single crystal form without impurity ph...

Embodiment 2

[0039] Low-purity raw material 1.5mmol FAI (formamidine hydroiodide, NH 2 CHNH 2 I, purity 98%) and 1.5mmolPbI 2 (lead iodide, purity 98%) was dissolved in 1 ml of ethylene glycol methyl ether solvent, and stirred continuously for 1 h to obtain a mixed solution, which was then filtered and transferred to a small beaker. Inject 2ml of ether into the beaker, stir for 30 seconds, and precipitate yellow perovskite crystallite precipitate FAPbI at the bottom of the beaker 3 . Precipitate FAPbI from the precipitated perovskite crystallites 3 Use diethyl ether to wash 3 times, and remove residual diethyl ether by room temperature vacuum drying, obtain the perovskite material powder FAPbI of this embodiment 3 (delta phase), calculated yield 90%.

[0040] The perovskite material powder FAPbI that the present embodiment makes 3 The XRD diffraction peak position of the photo is as Figure 4 shown. The XRD pattern shows that the perovskite material powder is a single crystal δ pha...

Embodiment 3

[0042] Low-purity raw material 1.5mmol MAI (methylamine hydroiodide, CH 3 NH 3 I, purity 98%) and 1.5mmol PbI 2 (lead iodide, purity 98%) was dissolved in 1 ml of γ-butyrolactone solvent, and stirred continuously for 1 h to obtain a mixed solution, which was then filtered and transferred to a small beaker. Inject 2ml of ether into the beaker, stir for 30 seconds, and precipitate black perovskite crystallite precipitate MAPbI at the bottom of the beaker 3 . Precipitate MAPbI from the precipitated perovskite crystallites 3 Use ether to wash 3 times, and remove the residual ether by vacuum drying at room temperature to obtain the perovskite material powder MAPbI of this embodiment 3 , and the calculated yield was 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com