Grease-based diethanolamide polyoxyethylene ether, preparation method thereof and phosphate

A technology of polyoxyethylene ether phosphate and base diethanolamide, which is applied in the field of grease-based diethanolamide polyoxyethylene ether and its preparation, and phosphoric acid ester, and can solve the problem of fatty acid alkanolamide polyoxyethylene ether deep color and amine value To solve the problems of high free amine content and high equipment requirements, and achieve the effects of reducing free amine content and color value, improving surface activity, emulsifying power and dispersing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

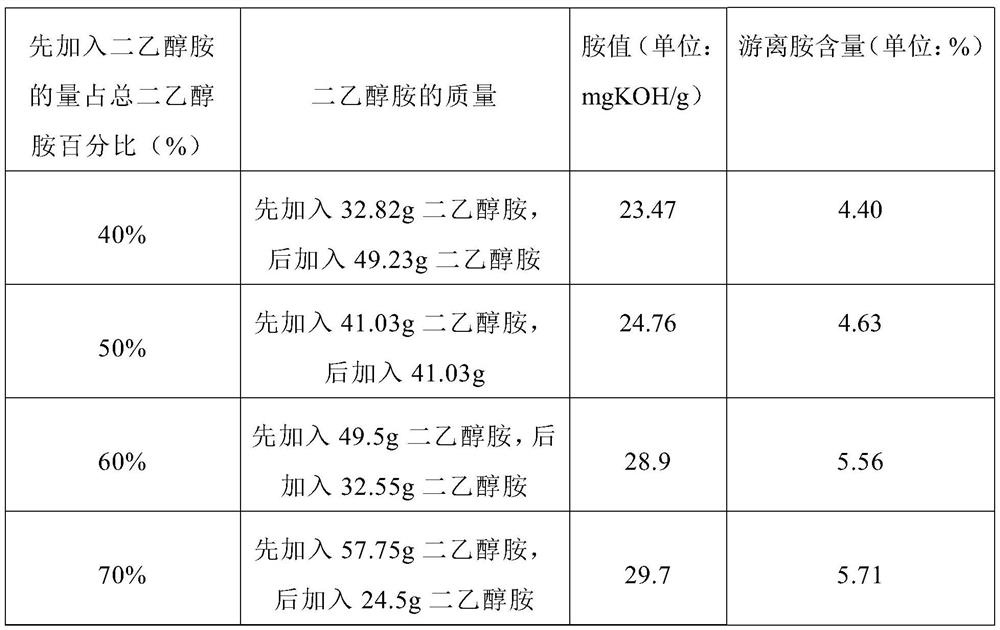

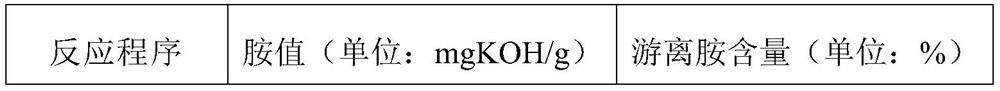

[0043] The present embodiment provides a kind of preparation method of grease-based diethanolamide polyoxyethylene ether, comprising the following steps:

[0044] (1) Vacuumize the reaction kettle for nitrogen replacement, put 180g of palm kernel oil into the reaction kettle, slowly put in 32.82g of diethanolamine, raise the temperature to 140°C, react for 4h, cool down to 80°C, and put in potassium hydroxide. Diethanolamine solution (diethanolamine 49.23g, potassium hydroxide 2.62g), reacted for 4h, and discharged to obtain palm kernel oil diethanolamide.

[0045] (2) drop into 100g palm kernel oil diethanolamide in autoclave, vacuumize, pass into nitrogen, control reaction system pressure is 0.02MPa, add 0.5g sodium carbonate, and slowly pass into 72g ethylene oxide, be warming up to 100 °C, reacted for 4 hours, cooled to 70 °C, and discharged to obtain palm kernel oil diethanolamide polyoxyethylene ether.

[0046] This embodiment also provides a preparation method of fat-b...

Embodiment 2

[0049] The present embodiment provides a kind of preparation method of grease-based diethanolamide polyoxyethylene ether, comprising the following steps:

[0050] (1) Vacuumize the reaction kettle for nitrogen replacement, put 180g of palm kernel oil into the reaction kettle, slowly put in 41.03g of diethanolamine, raise the temperature to 140°C, react for 4h, cool down to 80°C, and put in potassium hydroxide. Diethanolamine solution (diethanolamine 41.03g, potassium hydroxide 2.6g), reacted for 4h, and ended the reaction to obtain palm kernel oil diethanolamide.

[0051](2) drop into 100g palm kernel oil diethanolamide in autoclave, vacuumize, pass into nitrogen, control reaction system pressure is 0.02MPa, add 0.5g sodium carbonate, and slowly pass into 72g ethylene oxide, be warming up to 100 °C, reacted for 4 hours, cooled to 70 °C, and discharged to obtain palm kernel oil diethanolamide polyoxyethylene ether.

[0052] This embodiment also provides a preparation method of...

Embodiment 3

[0055] The present embodiment provides a kind of preparation method of grease-based diethanolamide polyoxyethylene ether, comprising the following steps:

[0056] (1) Vacuumize the reaction kettle for nitrogen replacement, put 180g of palm kernel oil into the reaction kettle, slowly put in 32.82g of diethanolamine, raise the temperature to 140°C, react for 4h, cool down to 80°C, and put in potassium hydroxide. Diethanolamine solution (diethanolamine 49.23g, potassium hydroxide 2.62g), reacted for 4h, and ended the reaction to obtain palm kernel oil diethanolamide.

[0057] (2) drop into 100g palm kernel oil diethanolamide in autoclave, vacuumize, feed nitrogen, control reaction system pressure is 0.04MPa, add 0.5g sodium carbonate, and slowly feed 72g ethylene oxide, be warming up to 120 °C, reacted for 4 hours, cooled to 60 °C, and discharged to obtain palm kernel oil diethanolamide polyoxyethylene ether.

[0058] This embodiment also provides a preparation method of fat-bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com