Pretreatment method for brewing grape wine by adopting flash evaporation process and grape wine

A wine and flashing technology, applied in the wine field, can solve the problems of unstable flashing effect, low work efficiency, irregular operation, etc., and achieve the effect of increasing the instructions for equipment use, broadening the sanitary conditions, and avoiding auxiliary procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

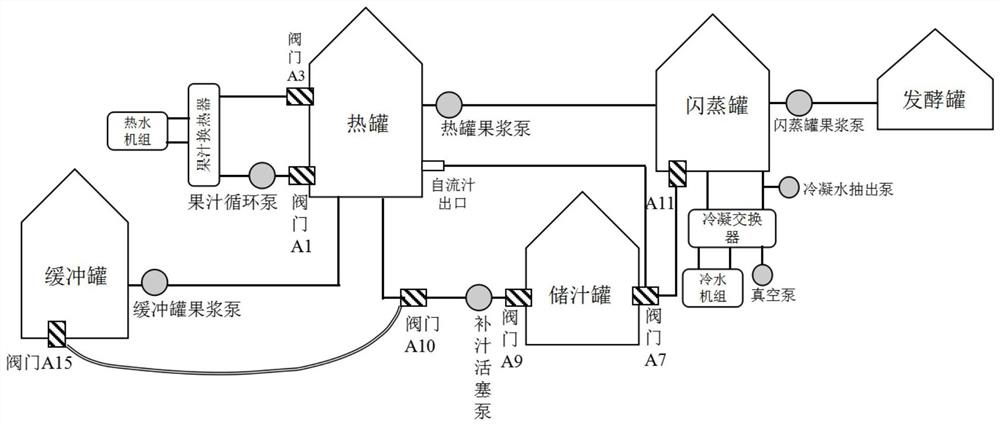

[0132] The pretreatment method that adopts the flash steaming technique brewing wine that present embodiment provides is as follows: figure 1 As shown, the method specifically includes the following steps:

[0133] (A), pre-production preparation, cleaning and project inspection:

[0134] For the first use within a year, check and prepare the following items:

[0135] a. Check buffer tanks, hot tanks, flash tanks, juice pumps or pulp pumps, system piping, valves, liquid level gauges and other equipment units and accessories for water, grape pomace, tartar, pigmentation and Other dirt, whether there is any peculiar smell; and then thoroughly clean the whole set of equipment with the cleaning procedure of clear water-lye-clear water-acid solution-clear water, wherein the lye used is sodium hydroxide solution with a mass fraction of 1.5%, acid solution Be the citric acid solution that mass fraction is 2%;

[0136] b. Connect the material pipeline outlet of the flash pulp pump ...

Embodiment 2

[0159] The pretreatment method that adopts the flash steaming process to brew wine provided by the present embodiment comprises the following steps:

[0160] (A), pre-production preparation, cleaning and project inspection:

[0161] a. Since the brewing device is continuously flashing, clean water should be used to clean the device before production;

[0162] b. Connect the material pipeline outlet of the flash pulp pump to the fermenter with a hose;

[0163] c. Check that the doors of the connected tanks are closed tightly, the bayonet of the grape inlet and outlet connecting hoses is fastened, and the tank body and pipeline valves are in the correct position;

[0164] d. Turn on the hot water unit and keep the water temperature at the heat exchange return port up to 93°C.

[0165] (B), grape destemming and caching: the flash system works continuously, and the destemming crusher only performs destemming work; the freshly harvested Marselan red grapes (sugar content 216.5g / L...

Embodiment 3

[0179] The pretreatment method that adopts the flash steaming process to brew wine provided by the present embodiment comprises the following steps:

[0180] (A), pre-production preparation, cleaning and project inspection:

[0181] a. Due to non-continuous flash production for 5 days, hygienic inspection should be carried out on equipment units and accessories such as buffer tanks, hot tanks, flash tanks, juice pumps or pulp pumps, system pipelines, valves, liquid level gauges, etc. before production, Clean and odorless, rinse with clean water.

[0182] b. Connect the material pipeline outlet of the flash pulp pump to the fermenter with a hose;

[0183] c. Check that the doors of the connected tanks are closed tightly, the bayonet of the grape inlet and outlet connecting hoses is fastened, and the tank body and pipeline valves are in the correct position.

[0184] d. Turn on the hot water unit and keep the water temperature at the heat exchange outlet at 90°C to 91°C.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com