Nickel hydroxide and preparation method thereof

A technology of nickel hydroxide and magnesium oxide, applied in the field of hydrometallurgy, can solve the problem of high cost of nickel hydroxide, and achieve the effects of high nickel content in products, simple process flow and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

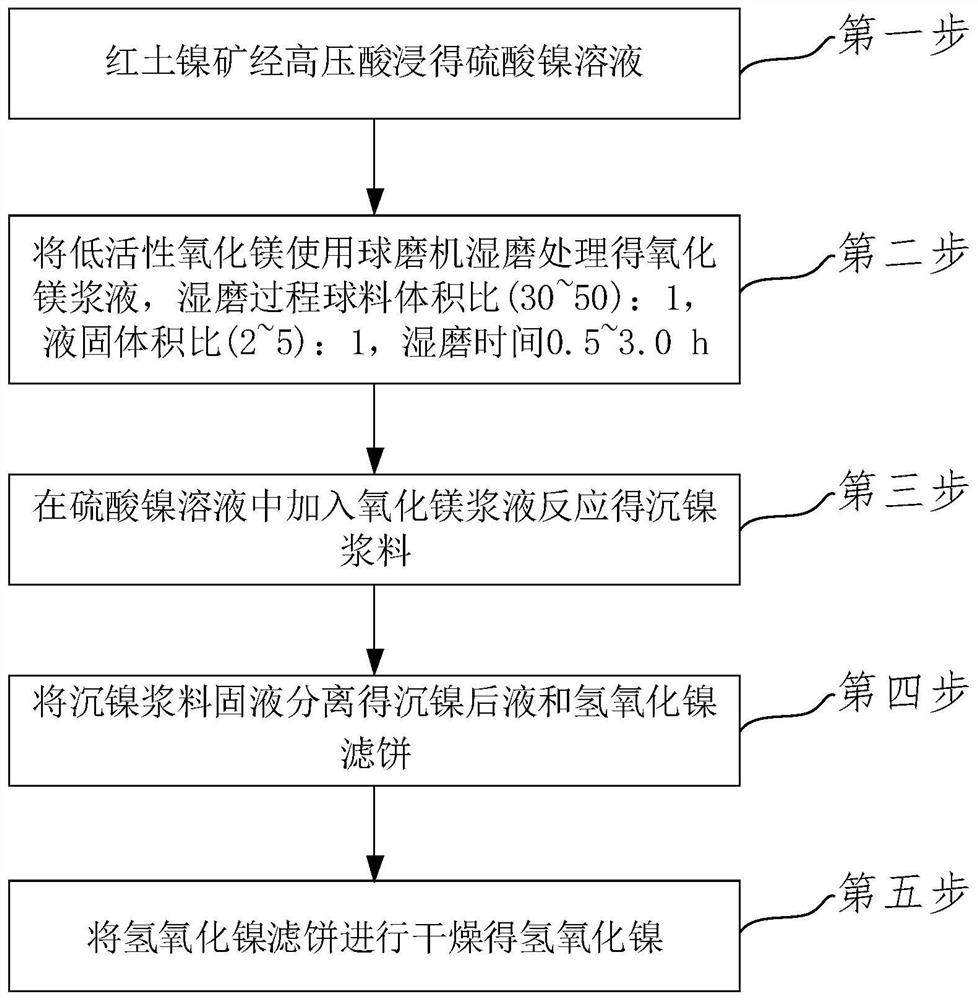

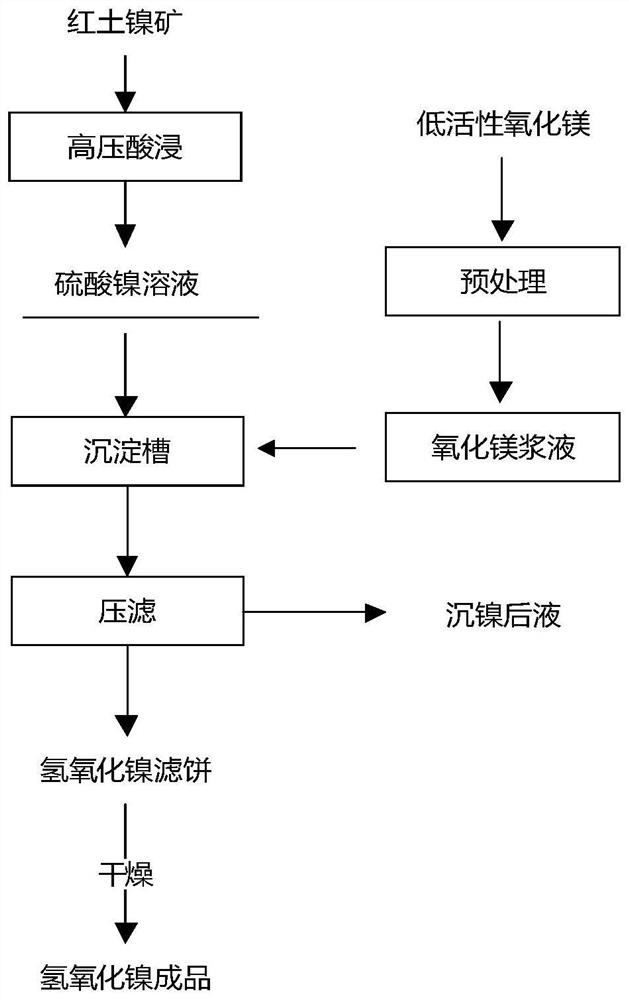

[0033] The present application provides a method for preparing nickel hydroxide, see figure 1 and figure 2 ,include:

[0034] Step: laterite nickel ore under high pressure acid leaching of nickel sulfate solution obtained.

[0035] Specifically, after the use of laterite nickel ore by crushing, washing, pulp concentration, etc. Step concentrated sulfuric acid and a high pressure acid leaching and other Fe-Al to give the nickel sulfate solution, nickel sulfate solution containing nickel ions mainly, as well as some cobalt ions and manganese ion.

[0036] Step two: the low activity magnesium oxide wet grinding using a ball mill handled magnesia slurry, wet milling process the volume ratio of ball to powder (30 to 50): 1, the volume of liquid to solid ratio (2 to 5): 1, wet milling time 0.5 ~ 3.0h.

[0037] Specifically, the active magnesium oxide chemical composition, physical form like ordinary index and MgO is not much difference, but some indicators active magnesium oxide and mag...

Embodiment 1

[0062] The red soil nickel ore is shown in high pressure acid immersion and iron aluminum to obtain a nickel sulfate solution component as shown in Table 1 below.

[0063] Table 1 Nickel sulfate solution ingredients

[0064] Ni g / L Fe g / L Al CO Mn pH 3.51 0.002 0.003g / L 0.42 0.57 4.4

[0065] "Active -40" magnesium oxide (66mgi) 2 / Gmgo, a heap density of 0.10 g / ml, MgO92.3%) The spherical mill is wet milling, the liquid solid volume ratio 4: 1, the spherical volume ratio 40: 1, the abrasive 2H, and the abrasive are obtained to obtain magnesia slurry.

[0066] The magnesium oxide slurry is slowly pumped into the sink contained in the sulfate solution, and the nickel tank pH to 7.5 is adjusted, and the stirring reaction is stably stirred from the sink.

[0067] After the reaction, the sink is separated by the pressure filtrate to obtain a sinking liquid and a nickel hydroxide cake, and the nickel hydroxide cake is sent to the drying step to obtai...

Embodiment 2

[0071] For the nickel sulfate solution of Example 1.

[0072] "Active-60" magnesium oxide (69mgi) 2 / Gmgo, a heap density of 0.14 g / ml, MgO 92.47%) The spherical mill wet milling treatment, the liquid solid volume ratio is 5: 1, the spherical volume ratio 35: 1, the abrasive 3H, and the abrasive are obtained to obtain magnesia slurry.

[0073] The magnesium oxide slurry is slowly pumped into the sulphic tank with a nickel sulfate solution, and the nickel tank pH to 8.0 is adjusted, and the stirring reaction is stably stirred 4H to obtain a sketch slurry.

[0074] After the reaction, the sinking of the sink is separated by the pressure filtrate to obtain a silicon hydroxide and a nickel hydroxide cake, and a nickel hydroxide cake is sent to the drying step to obtain a nickel hydroxide product of Example 2.

[0075] Composite organic LD-1MS with a volume concentration of 30% and a silicon reactation reaction, LD-1MS and (Ni + CO + Mn) mass ratio = 1.04: 1, after the reaction was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine absorption value | aaaaa | aaaaa |

| Iodine absorption value | aaaaa | aaaaa |

| Iodine absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com