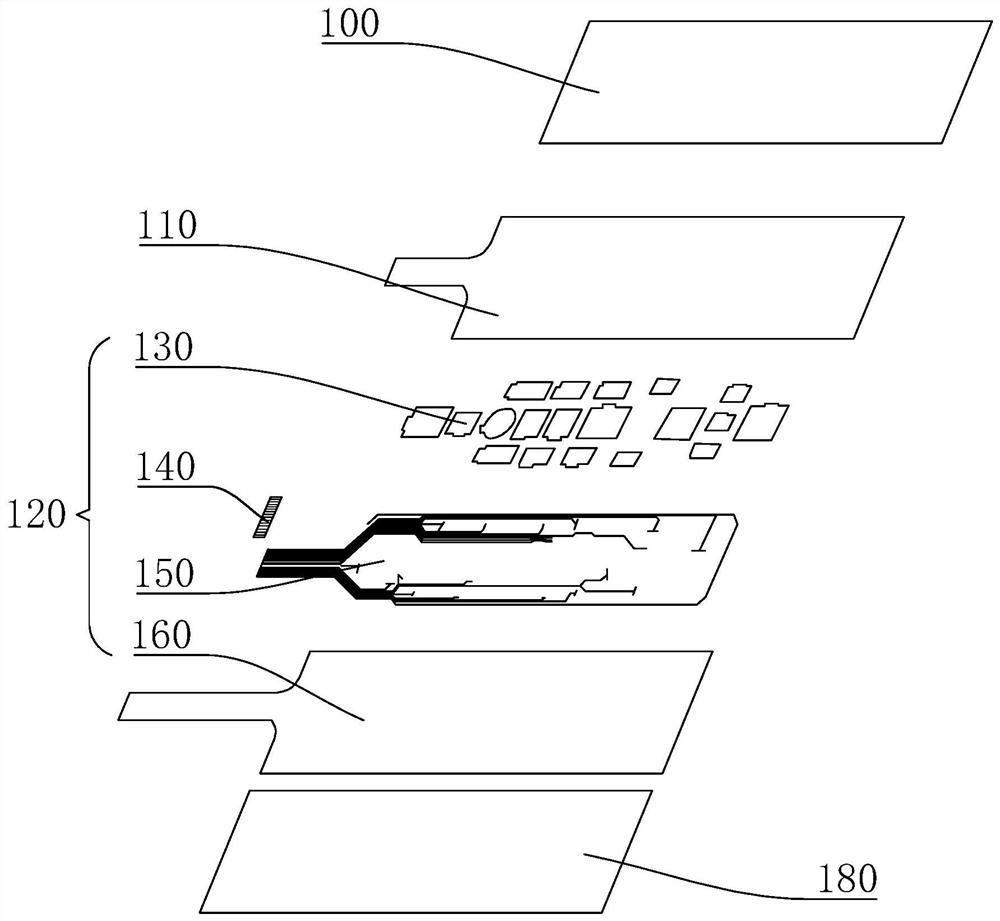

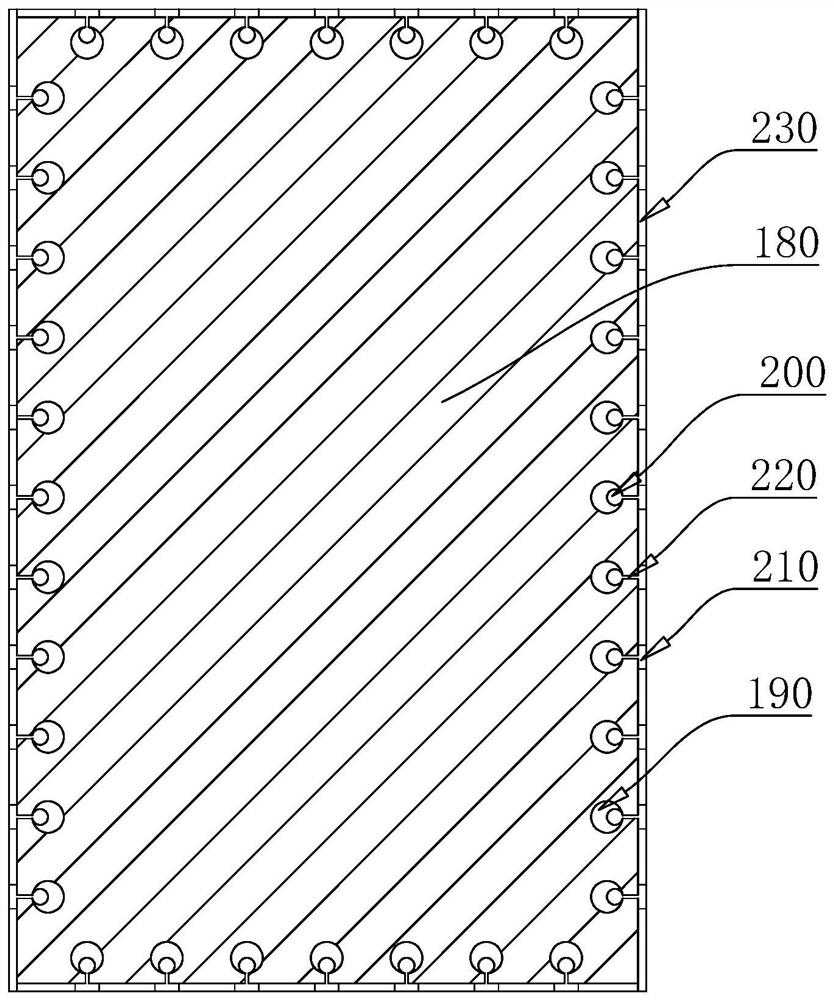

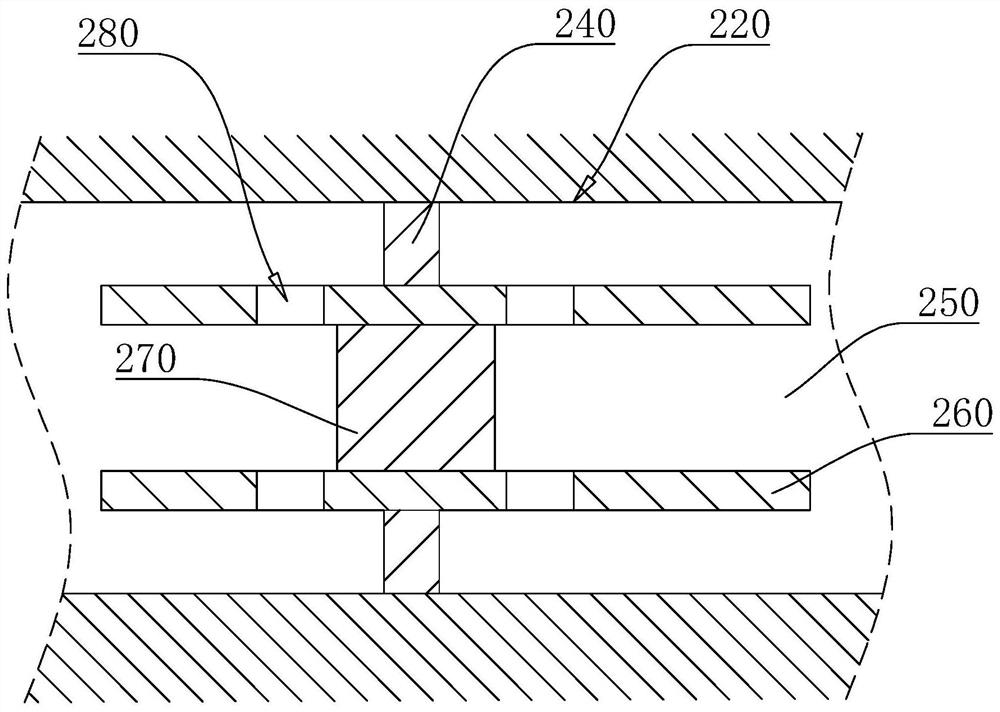

Touch switch with 3D effect

A touch switch, 3D effect technology, used in electronic switches, adhesive types, polyurea/polyurethane adhesives, etc. Insufficient and other problems, to achieve the effect of improving service life and good installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0048] A hot-melt adhesive, made of the following raw materials in parts by weight: 300g poly-1,4-butylene adipate; 30g dimethylol propionic acid; 30g sodium ethylenediamine sulfonate; 100g iso Phorne diisocyanate; 50g hexamethylene diisocyanate; 20g1,4-butanediol; 50g acetone; 50g triethylamine;

[0049] Wherein polyadipate-1,4-butylene glycol ester is selected from West Asia Chemical Technology Co., Ltd. polyadipate-1,4-butylene glycol ester with a molecular weight of 2000; dimethylol propionic acid, isophor Ketone diisocyanate, hexamethylene diisocyanate, and 1,4-butanediol were all selected from Shanghai Jinjinle Industrial Co., Ltd.; sodium ethylenediaminoethanesulfonate was selected from Hubei Hongxin Ruiyu Fine Chemical Co., Ltd.;

[0050] A kind of preparation technology of hot-melt adhesive specifically comprises the following processing steps:

[0051] Step 1, adding 300g of polyadipate-1,4-butylene adipate with a molecular weight of 2000 in proportion to a three-ne...

preparation example 2-5

[0056] The difference between the proportioning parameters and process parameters of the raw materials in the preparation examples 2-5 and the preparation example 1 is recorded in Table 1, and the rest are the same as the preparation example 1.

[0057] Ratio parameters and process parameters of raw materials in table 1 preparation example 2-5 hot melt adhesive

[0058]

[0059]

preparation example 6

[0061] A heating agent, made of the following raw materials in parts by weight: 12g Al powder; 10g activated carbon;

[0062] A preparation process of exothermic agent specifically comprises the following process steps:

[0063] Take Al 2 o 3 Raw material, the Al 2 o 3 The raw materials were mechanically crushed and sieved with a 400-mesh sieve to obtain Al 2 o 3 powder, and then use hydrogen to Al 2 o 3 The powder undergoes hydrogenation reduction reaction to obtain Al powder with rough surface and spongy holes inside. Inert gas nitrogen is introduced into the Al powder, and then the particle size is added to the Al powder while maintaining the inert gas nitrogen. Activated carbon particles of 200 μm were filled with Al powder into the pores of the activated carbon particles to obtain a heat generating agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com