Dry land corn cultivation method

A corn cultivation and dryland technology, applied in the field of crop cultivation, can solve problems such as focusing on corn irrigation, and achieve the effects of improving adsorption and other properties, lowering pH value, and reducing soil salinity damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

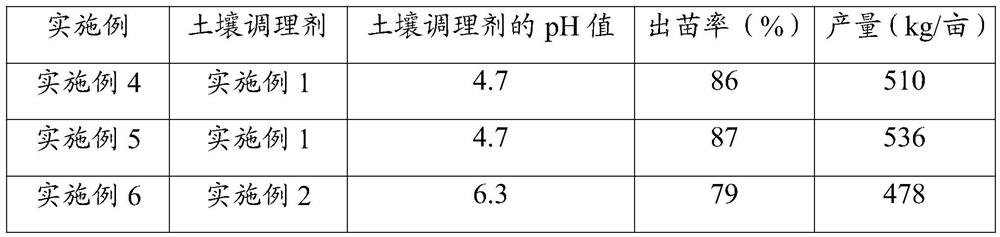

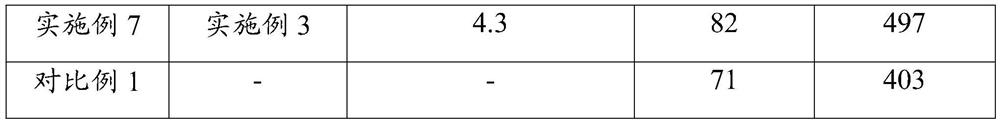

Examples

Embodiment 1

[0040] The present embodiment provides a kind of preparation method of soil conditioner, prepare according to the following method:

[0041] Described modified montmorillonite is prepared according to the following method:

[0042] Step 1. Add 4g of chitosan to 2L acetic acid solution to prepare a chitosan solution. Add 4g of crushed and sieved montmorillonite to the chitosan solution, stir at 60°C for 8h, and centrifuge until the supernatant The solution was neutral, and dried at 50°C for 18 hours to obtain chitosan@montmorillonite;

[0043] Step 2, adding 4g sodium lignosulfonate to 2L of ultrapure water to prepare sodium lignosulfonate solution, adding 4g chitosan@montmorillonite prepared in step 1 to sodium lignosulfonate solution, Stir at 50°C for 6h, after centrifugation, dry at 40°C for 12h to obtain sodium lignosulfonate@chitosan / montmorillonite;

[0044] Step 3, repeat the reaction of step 1-2 twice with sodium lignosulfonate / chitosan@montmorillonite, that is, repla...

Embodiment 2

[0047] The present embodiment provides a kind of preparation method of soil conditioner, prepare according to the following method:

[0048] Described modified montmorillonite is prepared according to the following method:

[0049] Step 1. Add 10g of chitosan to 2L acetic acid solution to prepare a chitosan solution. Add 6g of crushed and sieved montmorillonite to the chitosan solution, stir at 70°C for 6h, and centrifuge until the supernatant The solution was neutral, and dried at 60°C for 12 hours to obtain chitosan@montmorillonite;

[0050]Step 2, adding 10g of sodium lignosulfonate to 2L of ultrapure water to prepare sodium lignosulfonate solution, adding 6g of chitosan@montmorillonite prepared in step 1 to the sodium lignosulfonate solution, Stir at 60°C for 4h, and after centrifugation, dry at 60°C for 10h to obtain sodium lignosulfonate / chitosan@montmorillonite;

[0051] Step 3. Repeat the reaction of step 1-2 once with sodium lignosulfonate / chitosan@montmorillonite, ...

Embodiment 3

[0054] The present embodiment provides a kind of preparation method of soil conditioner, prepare according to the following method:

[0055] Described modified montmorillonite is prepared according to the following method:

[0056] Step 1. Add 12g of chitosan to 2L of acetic acid solution to prepare a chitosan solution. Add 5g of crushed and sieved montmorillonite to the chitosan solution, stir at 65°C for 7h, and centrifuge until the supernatant The solution was neutral, and dried at 55°C for 15 hours to obtain chitosan@montmorillonite;

[0057] Step 2, adding 12g of sodium lignosulfonate into 2L of ultrapure water to prepare sodium lignosulfonate solution, adding 5g of chitosan@montmorillonite prepared in step 1 into the sodium lignosulfonate solution, Stir at 55°C for 5h, and after centrifugation, dry at 55°C for 11h to obtain sodium lignosulfonate / chitosan@montmorillonite;

[0058] Step 3. Repeat the reaction of step 1-2 three times with sodium lignosulfonate / chitosan@mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com