Molten salt coating chemical activation method for preparing activated carbon with high specific surface area

A technology with high specific surface area and chemical activation, which is applied in the field of preparing activated carbon with high specific surface area by using the method of "molten salt coating chemical activation", which can solve the problems of complex process and expensive equipment, and achieve simple operation, low cost and excellent rate performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

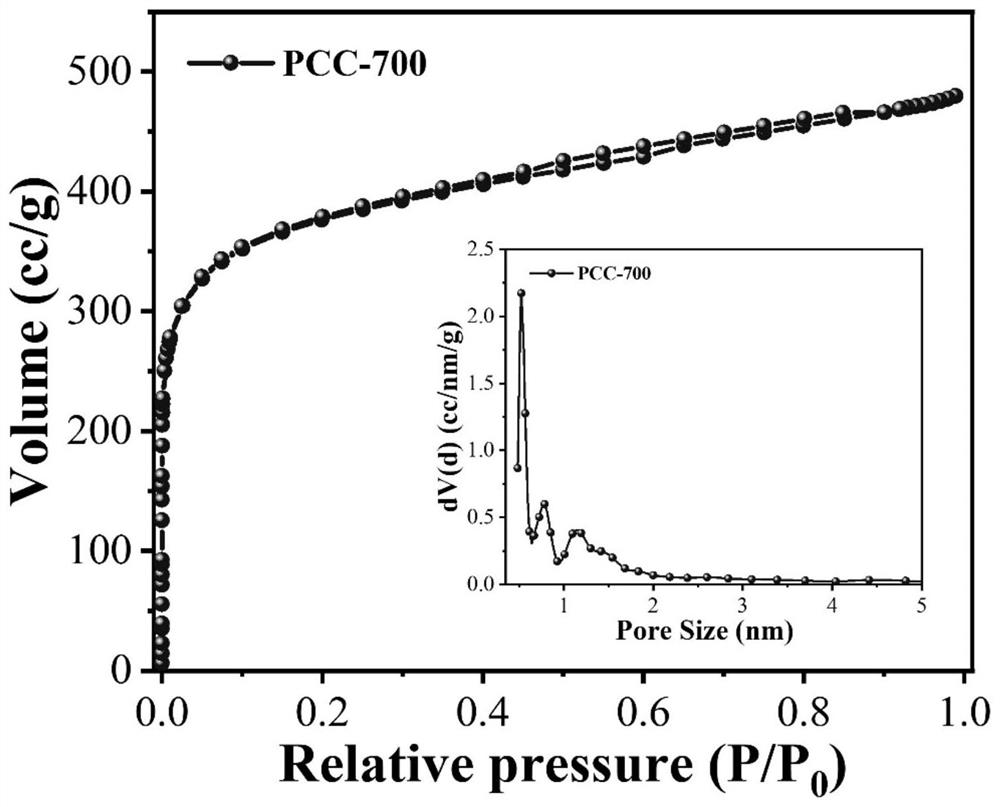

[0032] The present embodiment provides a kind of method for preparing PCC-700 gac, described method comprises the steps:

[0033] Step 1: Weigh petroleum coke and KOH according to the mass ratio of 1:3 and mix them;

[0034] Step 2: Coating the mixture of step 1 with KCl, coating a layer of KCl on the outside of the mixture, and placing it in a crucible with a cover;

[0035] Step 3: Place the covered crucible in Step 2 in a muffle furnace (air atmosphere) at 5°C min -1 The heating rate is kept at 700°C for 2h;

[0036] Step 4: The product activated in Step 3 was acid-washed with 5vol% HCl for 6 hours;

[0037] Step 5: Wash the product after pickling in step 4 with deionized water for 6 hours;

[0038] Step 6: Suction filter the product washed with water in Step 6, and then place it in a constant temperature drying oven at 70°C for 12 hours to obtain the prepared PCC-700 activated carbon.

Embodiment 2

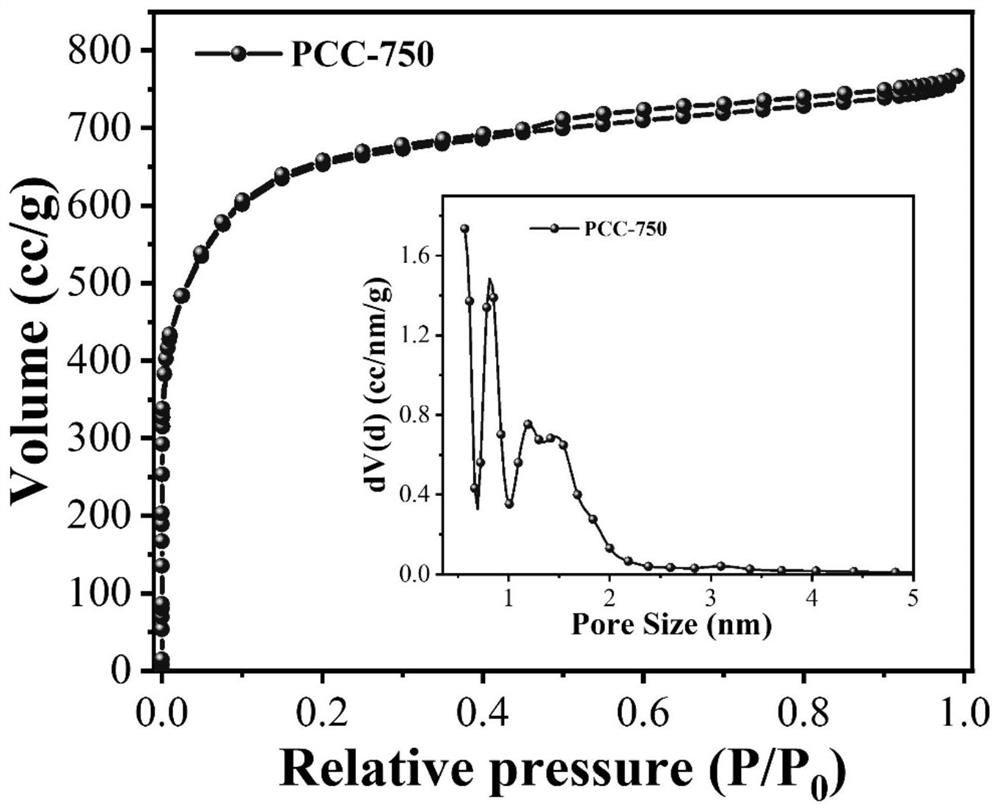

[0040] The present embodiment provides a kind of method for preparing PCC-750 gac, described method comprises the steps:

[0041] Step 1: Weigh petroleum coke and KOH according to the mass ratio of 1:3 and mix them;

[0042] Step 2: Coating the mixture of step 1 with KCl, coating a layer of KCl on the outside of the mixture, and placing it in a crucible with a cover;

[0043] Step 3: Place the covered crucible in Step 2 in a muffle furnace (air atmosphere) at 5°C min -1 The heating rate is kept at 750°C for 2h;

[0044] Step 4: The product activated in Step 3 was acid-washed with 5vol% HCl for 6 hours;

[0045] Step 5: Wash the product after pickling in step 4 with deionized water for 6 hours;

[0046] Step 6: Suction filter the product washed with water in Step 6, and then place it in a constant temperature drying oven at 70°C for 12 hours to obtain the prepared PCC-750 activated carbon.

Embodiment 3

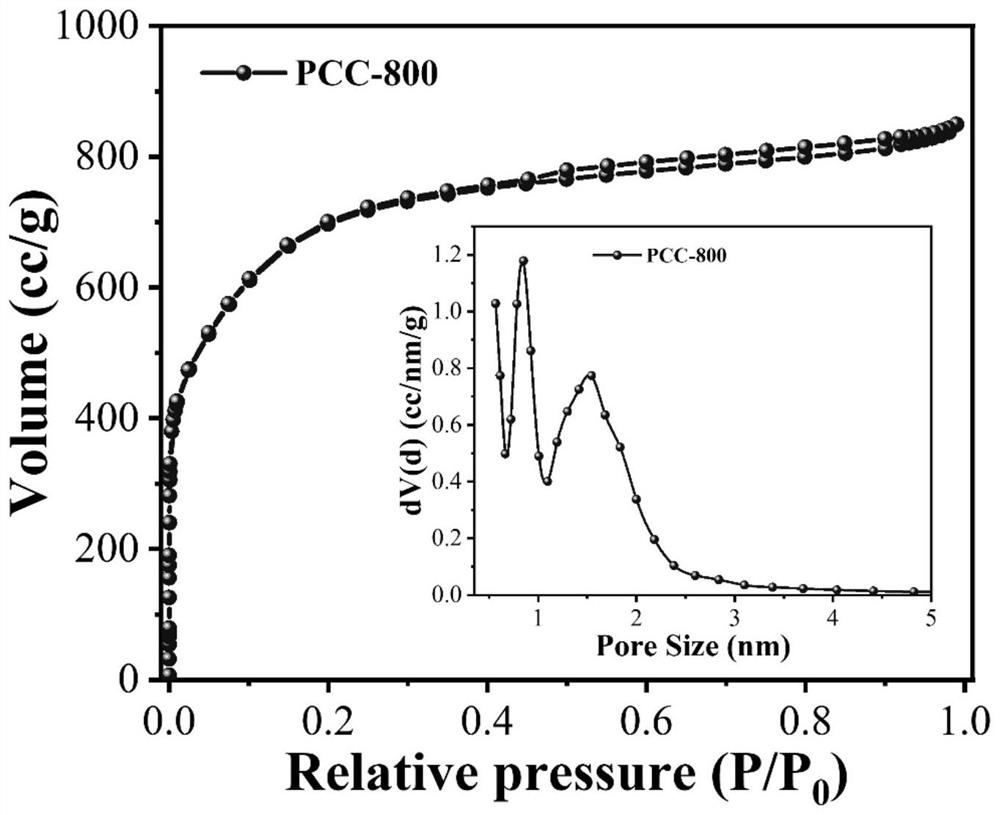

[0048] The present embodiment provides a kind of method for preparing PCC-800 gac, described method comprises the steps:

[0049] Step 1: Weigh petroleum coke and KOH according to the mass ratio of 1:3 and mix them;

[0050] Step 2: Coating the mixture of step 1 with KCl, coating a layer of KCl on the outside of the mixture, and placing it in a crucible with a cover;

[0051] Step 3: Place the covered crucible in Step 2 in a muffle furnace (air atmosphere) at 5°C min -1 The heating rate is kept at 800°C for 2h;

[0052] Step 4: The product activated in Step 3 was acid-washed with 5vol% HCl for 6 hours;

[0053] Step 5: Wash the product after pickling in step 4 with deionized water for 6 hours;

[0054] Step 6: Suction filter the product washed with water in Step 6, and then place it in a constant temperature drying oven at 70°C for 12 hours to obtain the prepared PCC-800 activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com