Inorganic single-component polymer ceramic tile gum and preparation method thereof

A one-component, polymer technology, applied in the field of inorganic one-component polymer tile adhesive and its preparation, can solve the problem of high cost and achieve the effects of low price, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

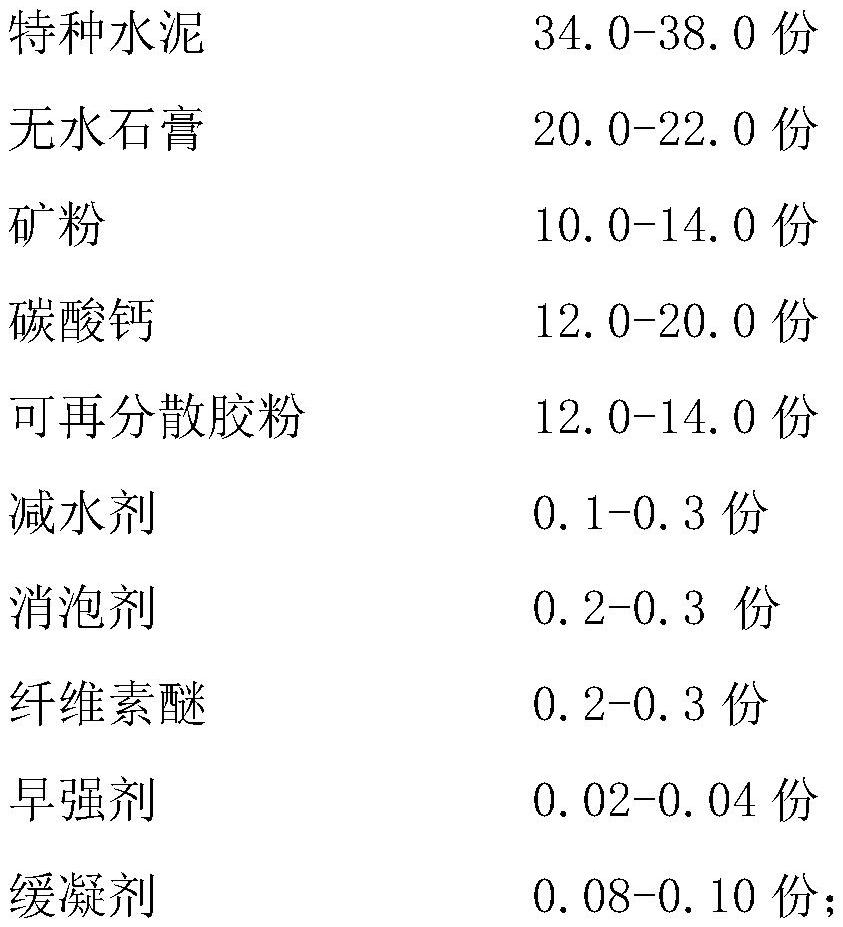

[0033] A kind of inorganic one-component polymer tile back glue described in the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0034]

[0035] Wherein, calcium carbonate is 200 mesh calcium carbonate.

[0036] The special cement is aluminate cement.

[0037] The anhydrite is 200 mesh natural anhydrite.

[0038] The redispersible rubber powder is styrene-acrylic rubber powder.

[0039] Cellulose ether is hydroxypropyl methylcellulose.

[0040] The water reducer is a polycarboxylate high-efficiency water reducer.

[0041] The early strength agent is lithium carbonate.

[0042] The retarder is DL-tartaric acid.

[0043] The preparation method of the described inorganic one-component polymer tile back glue mainly comprises the following steps carried out in sequence:

[0044] (1) Mix the retarder, early strength agent, cellulose ether, defoamer and water reducer evenly to obtain a masterbatch; ...

Embodiment 2

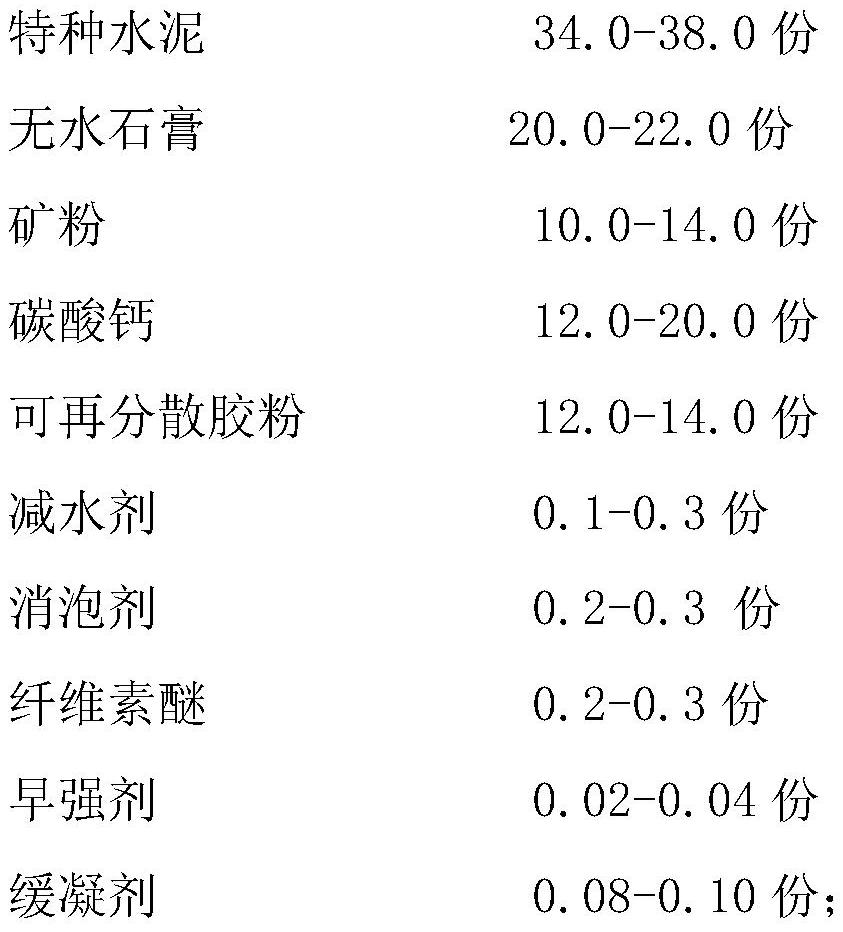

[0048] A kind of inorganic one-component polymer tile back glue described in the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0049]

[0050] Wherein, calcium carbonate is 200 mesh calcium carbonate.

[0051] The special cement is sulphoaluminate cement.

[0052] The anhydrite is 220 mesh natural anhydrite.

[0053] The redispersible rubber powder is styrene-acrylic rubber powder.

[0054] Cellulose ether is hydroxypropyl methylcellulose.

[0055] The water reducer is a polycarboxylate high-efficiency water reducer.

[0056] The early strength agent is aluminum sulfate.

[0057] The retarder is DL-tartaric acid.

[0058] The preparation method of the described inorganic one-component polymer tile back glue mainly comprises the following steps carried out in sequence:

[0059] (1) Mix the retarder, early strength agent, cellulose ether, defoamer and water reducer evenly to obtain a masterba...

Embodiment 3

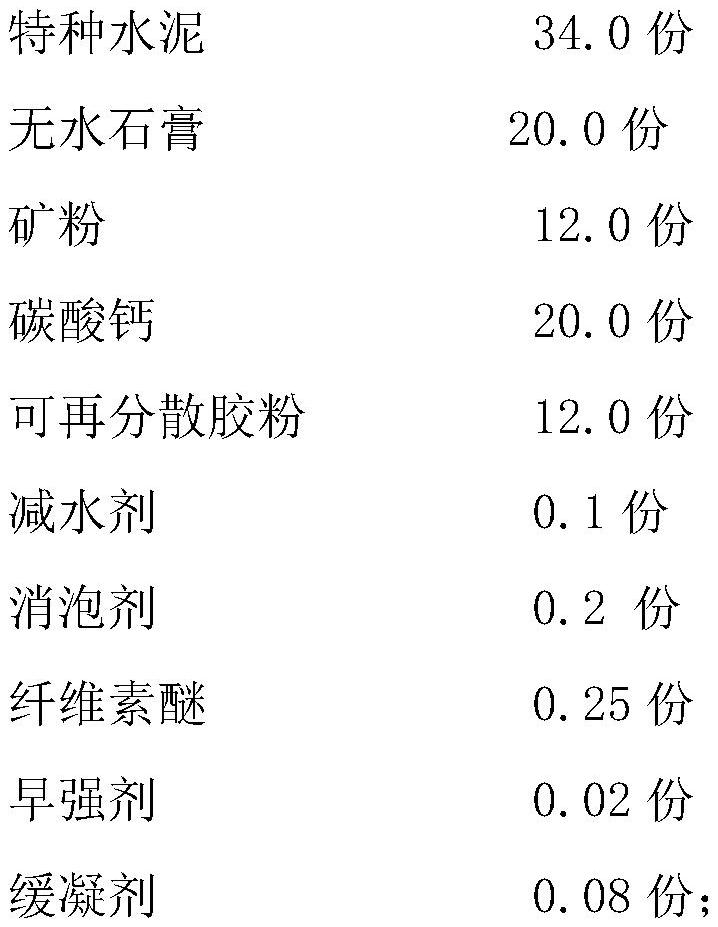

[0063] A kind of inorganic one-component polymer tile back glue described in the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0064]

[0065] Wherein, calcium carbonate is 200 mesh calcium carbonate.

[0066] The special cement is aluminate cement.

[0067] The anhydrite is any combination of 180 mesh natural anhydrite and 200 mesh natural anhydrite.

[0068] The redispersible rubber powder is styrene-acrylic rubber powder.

[0069] Cellulose ether is hydroxypropyl methylcellulose.

[0070] The water reducer is a polycarboxylate high-efficiency water reducer.

[0071] The early strength agent is aluminum sulfate.

[0072] The retarder is DL-tartaric acid.

[0073] The preparation method of the described inorganic one-component polymer tile back glue mainly comprises the following steps carried out in sequence:

[0074] (1) Mix the retarder, early strength agent, cellulose ether, defoamer and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com