A composite thermal insulation pad and its manufacturing process

A manufacturing process and a technology for thermal insulation pads, applied in the field of heat-resistant materials, can solve the problems of limiting the application of pure silica aerogel, serious aerogel cracking, poor integrity, etc., achieving low environmental damage, high insulation performance, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

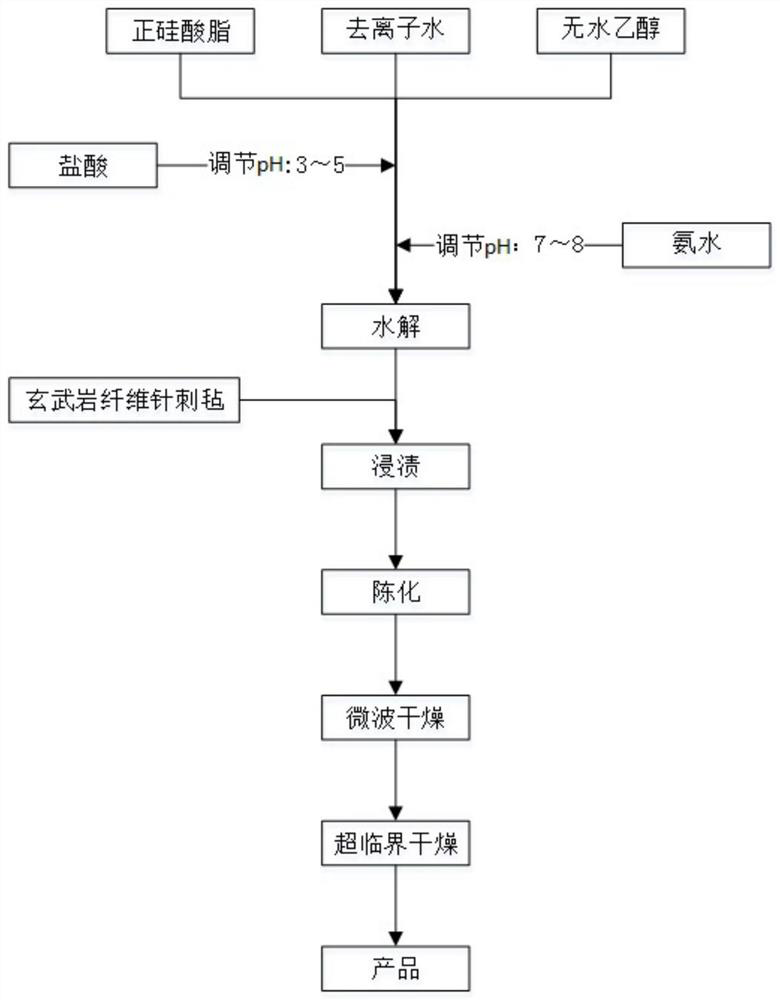

[0041] A manufacturing process of a composite thermal insulation pad, the manufacturing process of the thermal insulation pad comprises the following steps: figure 1 shown,

[0042] S1. Prepare aerogel precursor hydrolyzate: select 50 grams of orthosilicate and a hydrolyzing agent (100 grams of deionized water and 300 grams of anhydrous ethanol) according to the proportion and mix, first add hydrochloric acid solution to adjust the pH value to 3-5 , carry out the first stirring for 15 minutes, then add ammonia water to adjust the pH value to 7-8, and carry out the second stirring for 15 minutes to obtain aerogel precursor hydrolyzate;

[0043] S2. Impregnation substrate: The basalt fiber needle-punched felt substrate with a thickness of 1 mm is placed in the aerogel precursor hydrolyzate for 30 seconds through the unwinder, and then the aerogel precursor is squeezed and wound through the winder. The basalt fiber needle-punched felt base material after the hydrolyzate is obtai...

Embodiment 2

[0046] A manufacturing process of a composite thermal insulation pad, the manufacturing process of the thermal insulation pad comprises the following steps: figure 1 shown,

[0047] S1. Prepare aerogel precursor hydrolyzate: select 200 grams of orthosilicate and a hydrolyzing agent (500 grams of deionized water and 850 grams of anhydrous ethanol) according to the corresponding proportions and mix, first add hydrochloric acid solution to adjust the pH to 3- 5. Carry out the first stirring for 60 minutes, then add ammonia water to adjust the pH to 7-8, and carry out the second stirring for 60 minutes to obtain aerogel precursor hydrolyzate;

[0048] S2. Impregnation substrate: The basalt fiber needle-punched felt substrate with a thickness of 20 mm is placed in the hydrolyzed solution of the aerogel precursor for 120 seconds through the unwinder, and then the aerogel precursor is squeezed and wound through the winder. The basalt fiber needle-punched felt base material after the...

Embodiment 3

[0051] A manufacturing process of a composite thermal insulation pad, the manufacturing process of the thermal insulation pad comprises the following steps: figure 1 shown,

[0052] S1, prepare aerogel precursor hydrolyzate: select 50 grams of orthosilicate and hydrolyzing agent (100 grams of deionized water and 300 grams of absolute ethanol) according to the corresponding proportion, mix well, first add hydrochloric acid solution to adjust the pH value to 3- 5. Carry out the first stirring for 15 minutes, then add ammonia water to adjust the pH to 7-8, and carry out the second stirring for 60 minutes to obtain aerogel precursor hydrolyzate;

[0053] S2. Impregnation substrate: The basalt fiber needle-punched felt substrate with a thickness of 1 mm is placed in the aerogel precursor hydrolyzate for 30 seconds through the unwinder, and then the aerogel precursor is squeezed and wound through the winder. The basalt fiber needle-punched felt base material after the hydrolyzate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com