Polyurethane material and preparation, recovery and regeneration methods thereof

A technology of polyurethane material and molding method, applied in the field of polyurethane, can solve the problems such as difficult recycling and reuse of polyurethane elastomer, narrow hardness range of high elastic elastomer, unfavorable sustainable development, etc. Improved performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

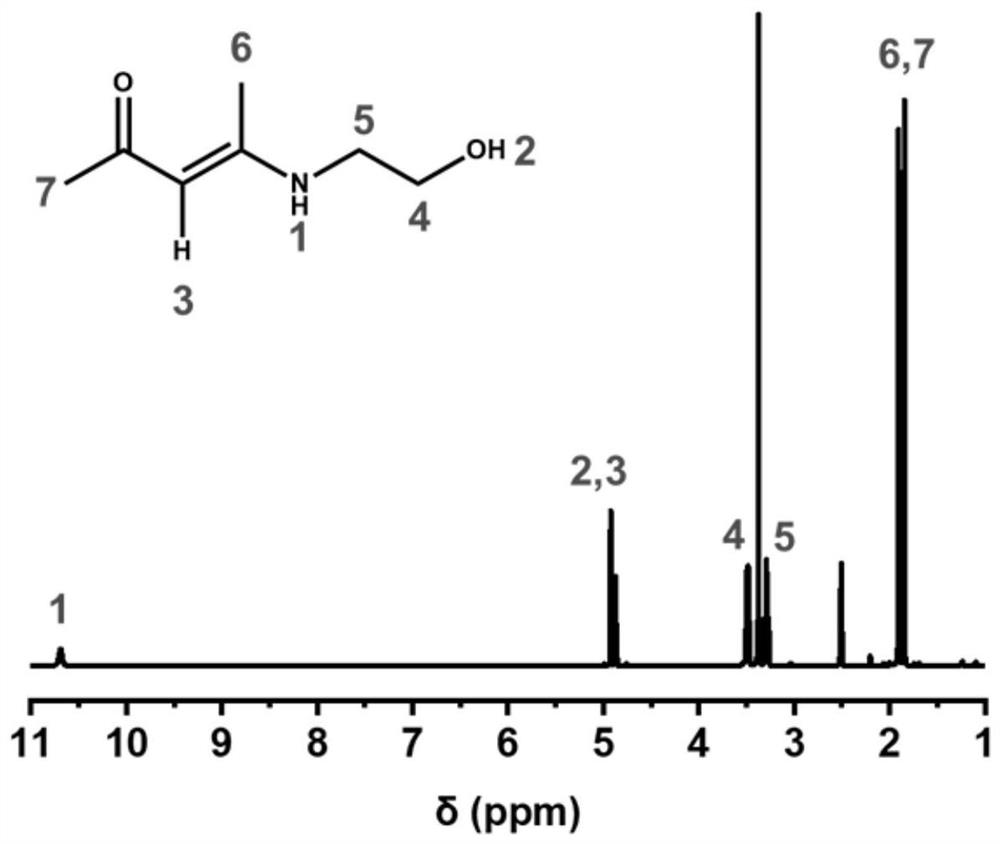

[0045]1.001 g of acetylacetone and 0.61 g of ethanolamine were dissolved in 5 mL of tetrahydrofuran, and reacted at 45° C. for 12 hours. The solvent was removed by rotary evaporation, and dried in a vacuum oven at 40° C. for 12 hours to obtain 4-((2-hydroxyethyl)amino)pent-3-en-2-one. figure 1 is the nuclear magnetic spectrum of the obtained 4-((2-hydroxyethyl)amino)pent-3-en-2-one.

Embodiment 2

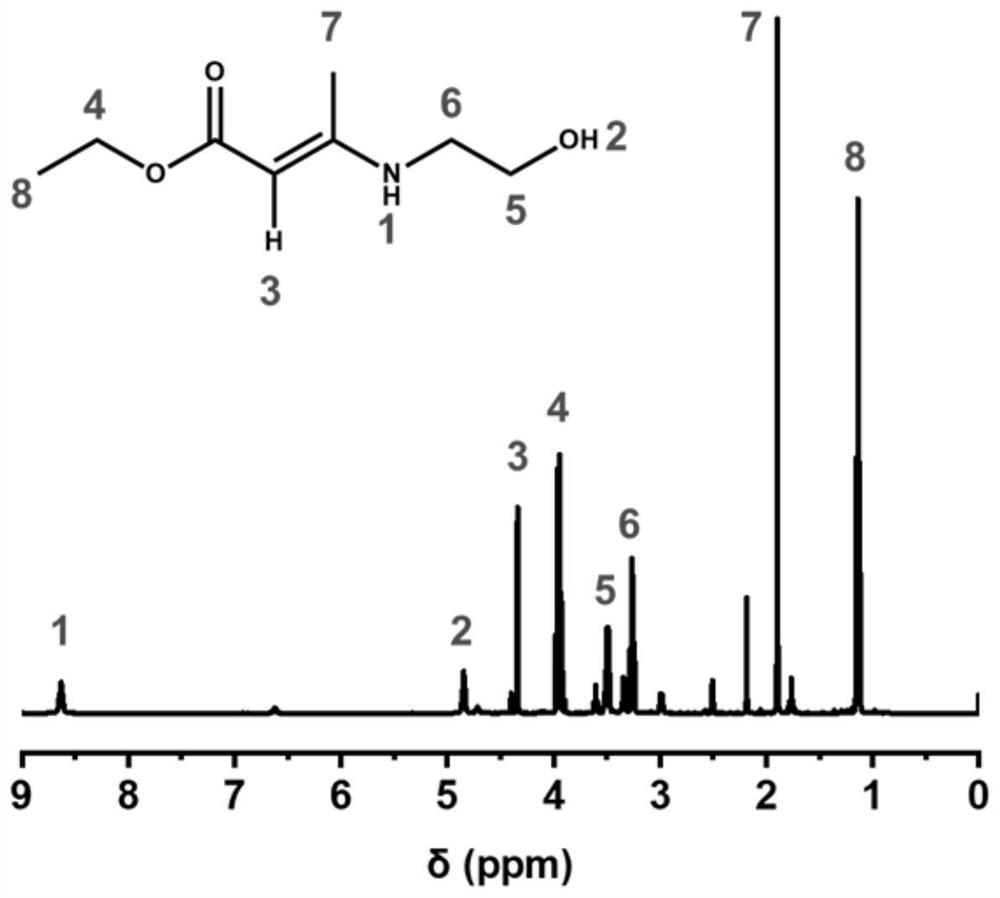

[0047] Dissolve 1.3014 g of ethyl acetoacetate and 0.61 g of ethanolamine in 5 mL of ethanol, and react at 45°C for 12 hours. The solvent was removed by rotary evaporation, and dried in a vacuum oven at 40° C. for 12 hours to obtain ethyl 3-((2-hydroxyethyl)amino)but-2-enoate. figure 2 It is the nuclear magnetic pattern of the obtained 3-((2-hydroxyethyl)amino)but-2-enoic acid ethyl ester.

Embodiment 3

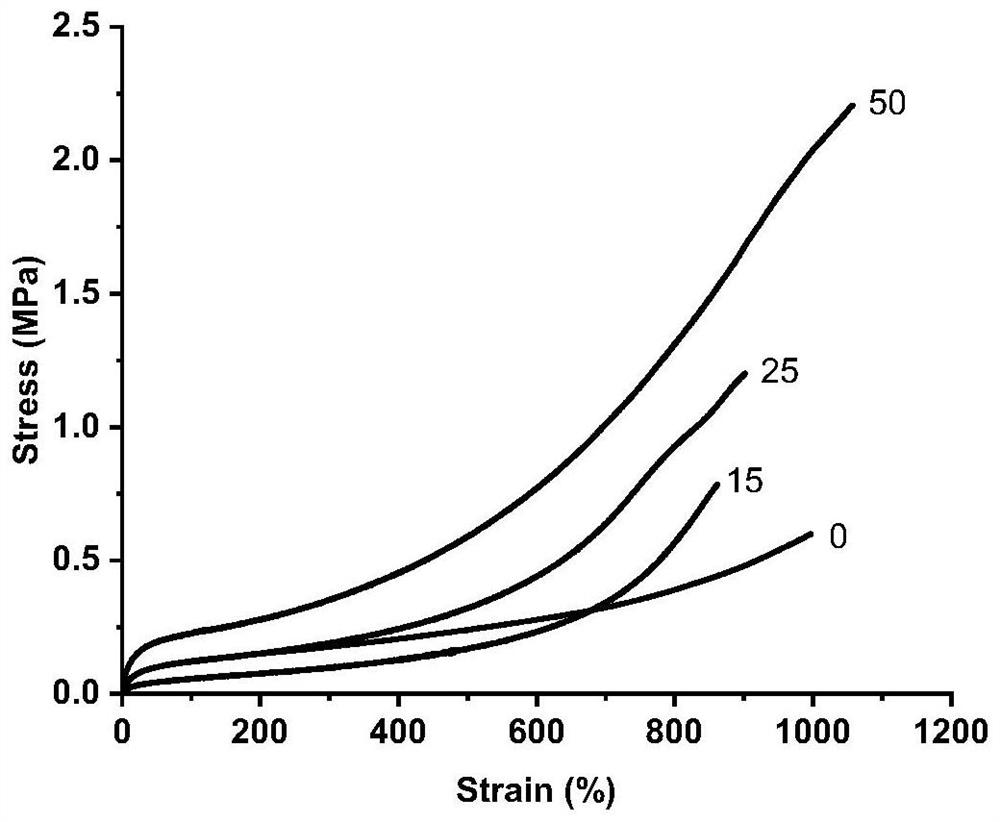

[0049] Dissolve 4 grams of PTMEG, 1.02 grams of IPDI and 0.03 grams of triethanolamine in 20 ml of tetrahydrofuran, heat at 50°C for 24 hours, remove the solvent at 100°C, and form the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com