Positive photosensitive composition

A technology of photosensitive composition and photosensitive resin, applied in the directions of optics, optomechanical equipment, and photosensitive materials for optomechanical equipment, etc., can solve the problem of insufficient heat resistance, peeling, and easy penetration between the pattern and the substrate and other problems, to achieve the effect of high solvent resistance, low dielectric constant, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0159] Production Example 1: Intermediate a1

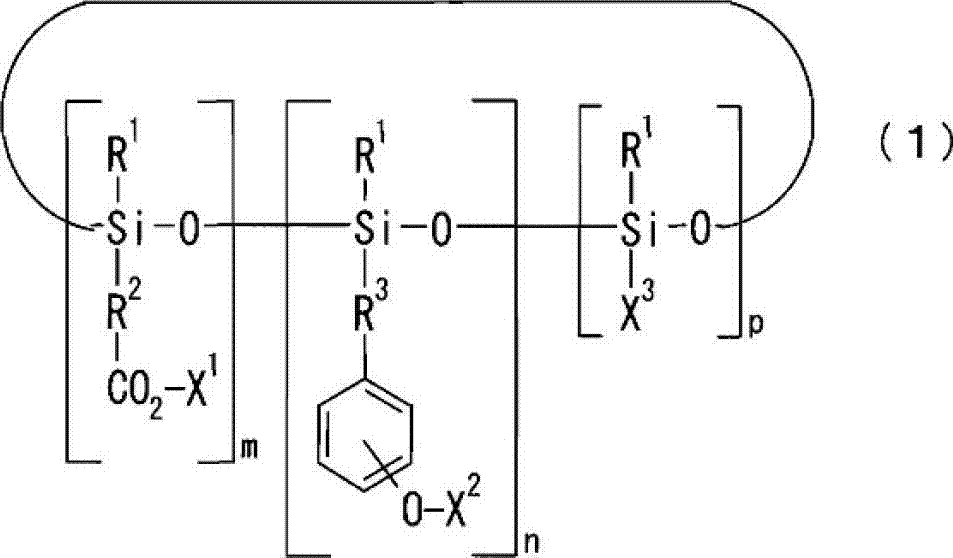

[0160] Into a glass reaction vessel equipped with a thermometer and a stirring device, 300 g of toluene as a solvent and 240 g of 2,4,6,8-tetramethylcyclotetrasiloxane (1 mole ), 64.1 g (0.5 moles) of tert-butyl acrylate as a compound represented by general formula (1m), 352 g (2 moles) of 4-tert-butoxystyrene as a compound represented by general formula (1n), and as a catalyst 0.05 g of platinum-divinyltetramethyldisiloxane complex (Karstedt catalyst) was reacted at 60° C. for 10 hours while stirring, and the solvent was distilled off to obtain intermediate al. Intermediate al is equivalent to the compound of general formula (1b) (R 1 = methyl, R 2 =R 3 = Ethylene, X 1 =X 2 = tert-butyl, m=0.5, n=2, p=1.5).

manufacture example 2

[0161] Production Example 2: Intermediate a2

[0162] In Production Example 1, as in Production Example 1, except that 102 g (0.5 moles) of tert-butyl 4-vinylbenzoate was used instead of 64.1 g (0.5 moles) of tert-butyl acrylate as the compound represented by the general formula (1m). The same operation gives intermediate a2. Intermediate a2 is equivalent to the compound of general formula (1b) (R 1 = methyl, R 2 =2-phenylethane-1,4'-diyl, R 3 = Ethylene, X 1 =X 2 = tert-butyl, m=0.5, n=2, p=1.5).

manufacture example 3

[0163] Production Example 3: Intermediate a3

[0164] Except in Production Example 1, as the compound represented by the general formula (1m), 204 g (1 mole) of tert-butyl 4-vinylbenzoate was used instead of 64.1 g (0.5 mole) of tert-butyl acrylate, and 4-tert-butyl Except that the amount of oxystyrene used was changed from 352 g (2 mol) to 264 (1.5 mol), the same operation as in Production Example 1 was carried out to obtain intermediate a3. Intermediate a3 is equivalent to the compound of general formula (1b) (R 1 = methyl, R 2 =2-phenylethane-1,4'-diyl, R 3 = Ethylene, X 1 =X 2 = tert-butyl, m=1, n=1.5, p=1.5).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com