Temperature-sensitive color-developing liquid crystal microcapsule and preparation method thereof

A technology of microcapsules and liquid crystals, applied in the directions of microcapsule preparation, microsphere preparation, liquid crystal materials, etc., can solve the problems of complex production process, intolerant of solvents, unfavorable for mass production, etc., to expand the scope of application, improve stability, The effect of improving solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

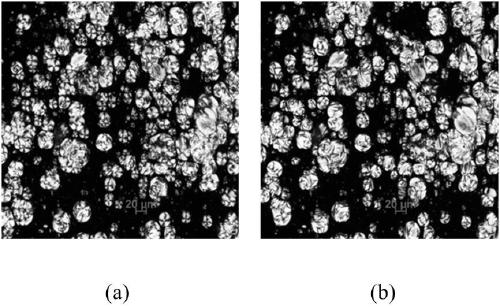

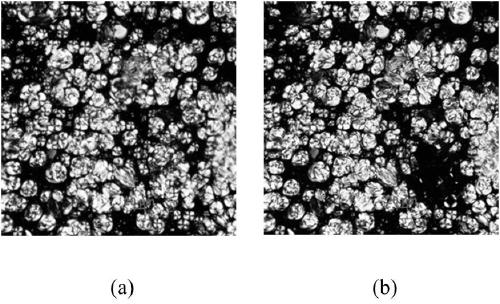

Image

Examples

Embodiment 1

[0034]Weigh 0.5 g of cholesterol propionate, 2.0 g of cholesterol nonanoate and 0.2 g of terephthaloyl chloride, and dissolve them in 15 g of ethyl acetate to form a uniform oil phase. 1.5 grams of OP-10 was dissolved in 75 grams of water to form aqueous phase A. 0.1 g of ethylenediamine was dissolved in 10 g of water to form aqueous phase B. Slowly add the oil phase prepared above into the water phase A, and keep stirring for 5 minutes to obtain an oil-in-water emulsion. Slowly add the aqueous phase B into the above emulsion under stirring conditions, stir and react at 50°C for 1.5 hours, then lower the temperature to 25°C, and continue stirring for 0.5 hours to obtain a dispersion of liquid crystal microcapsules with uniform particle size. The liquid crystal microcapsules are separated by centrifugation, washed with water for several times, and then centrifuged to obtain liquid crystal microcapsules with a particle diameter of 3-30 microns. The liquid crystal microcapsules...

Embodiment 2

[0036] Weigh 1.5 g of cholesterol propionate, 6 g of cholesterol nonanoate and 0.8 g of terephthaloyl chloride, and dissolve them in 15 g of ethyl acetate to form a uniform oil phase. 2 g of PVA was dissolved in 95 g of water, and 0.15 g of sodium bicarbonate was added to form aqueous phase A. 0.5 g of hexamethylenediamine and 0.3 g of triethylenetetramine were dissolved in 10 g of 2% PVA aqueous solution to form aqueous phase B. Slowly add the oil phase prepared above into the water phase A, and keep stirring for 5 minutes to obtain an oil-in-water emulsion. Slowly add the aqueous phase B into the above emulsion under stirring conditions, stir and react at 50°C for 1.5 hours, then lower the temperature to 25°C, and continue stirring for 0.5 hours to obtain a dispersion of liquid crystal microcapsules with uniform particle size. The liquid crystal microcapsules are separated by centrifugation, washed with water for several times and then centrifuged to obtain liquid crystal m...

Embodiment 3

[0038] Weigh 0.9 g of cholesterol propionate, 3.6 g of cholesterol nonanoate and 1 g of terephthaloyl chloride, and dissolve them in 15 g of ethyl acetate to form a uniform oil phase. 2 grams of PVA was dissolved in 95 grams of water to form aqueous phase A. 1 g of 2,4,4-trimethylhexamethylenediamine and 0.6 g of triethylenetetramine were dissolved in 10 g of 2% PVA aqueous solution to form aqueous phase B. Slowly add the oil phase prepared above into the water phase A, and keep stirring for 5 minutes to obtain an oil-in-water emulsion. Slowly add the aqueous phase B into the above emulsion under stirring conditions, stir and react at 50°C for 1.5 hours, then lower the temperature to 25°C, and continue stirring for 0.5 hours to obtain a dispersion of liquid crystal microcapsules with uniform particle size. The liquid crystal microcapsules are separated by centrifugation, washed with water for several times, and then centrifuged to obtain liquid crystal microcapsules with a pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com