Environment-friendly flame-retardant conductive foam, and preparation method and device thereof

A technology for conductive foam and preparation device, which is applied to equipment for manufacturing conductive/semi-conductive layers, lamination devices, cable/conductor manufacturing, etc. The effect of reducing the magnetic and shielding properties and enhancing the noise-cancelling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

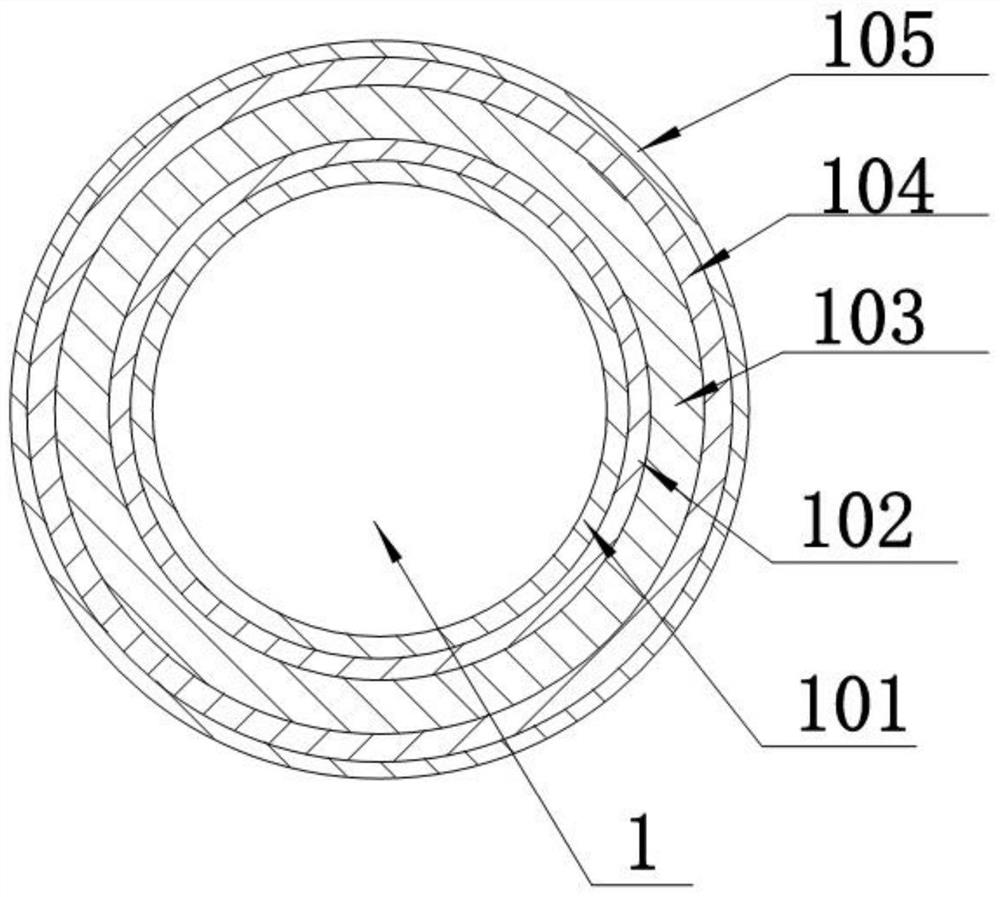

[0046] Such as Figure 1-9 As shown, an environmentally friendly flame-retardant conductive foam includes a conductive foam inner core 1, the outer periphery of the conductive foam inner core 1 is coated with a high-temperature resistant flame-retardant conductive elastic film 101, and the outer periphery of the high-temperature resistant flame-resistant conductive elastic film 101 is pasted with Copper-plated conductive cloth 102, the outer periphery of copper-plated conductive cloth 102 is coated with magnetic current layer 103, the outer periphery of magnetic current layer 103 is pasted with nickel-plated conductive cloth 104, and the outer surface of nickel-plated conductive cloth 104 is coated with an environmentally friendly water-based flame-retardant coating. Burning layer 105.

[0047] The high-temperature-resistant flame-retardant conductive elastic film 101 includes 10 parts of conductive metal nickel powder, 25 parts of type II ammonium polyphosphate (melamine-coat...

Embodiment 2

[0066] Because the spring is energized, the two ends of the spring generate magnetism. When the spring is pulled outward, because the end of the magnetic current layer 103 is affected by the magnetic field, the magnetic current layer 103 will be attracted by the spring, and the magnetic current layer 103 at both ends of the conductive foam will be lost. Product quality, in order to solve the problems referred to above, do following improvement on the basis of embodiment 1.

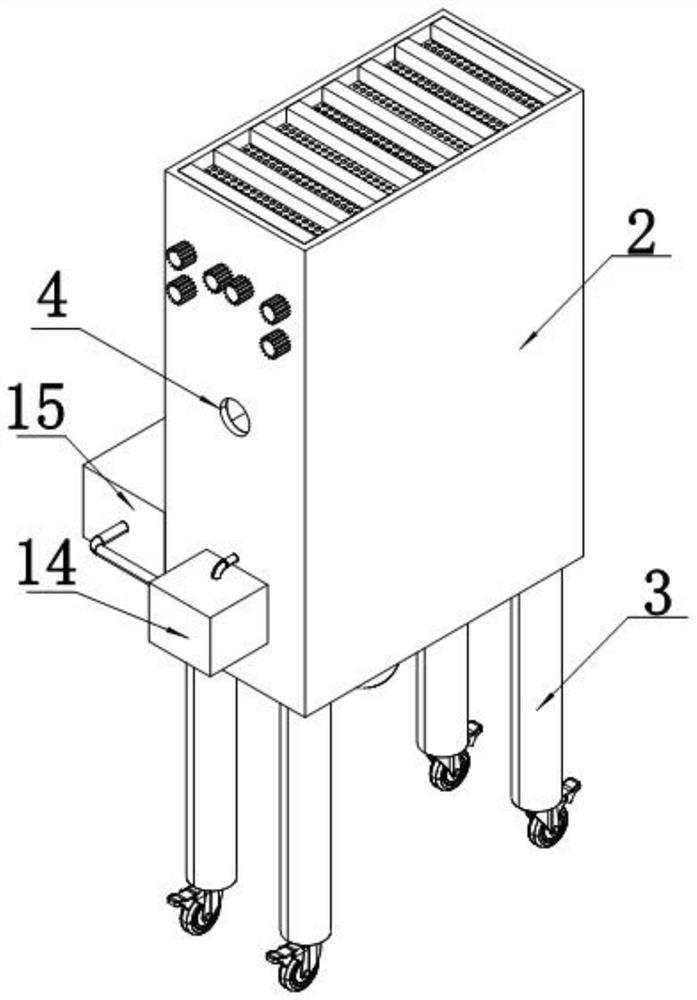

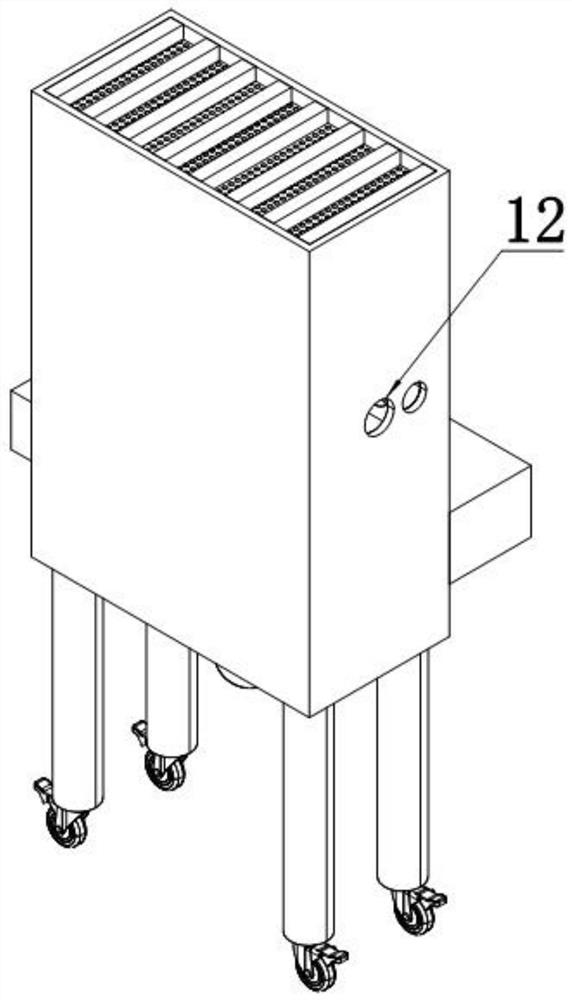

[0067] The left and right sides of the front side wall of the work box 2 are symmetrically provided with a second manipulator 16, and the second manipulator 16 includes two claw-type mechanical claws 1601, and the opposite sides of the two claw-type mechanical claws 1601 are provided with electrode sheets, and the second manipulator 16 passes through the The mechanical arm 1602 is connected with the output shaft of the rotating motor, and the rotating motor is fixedly connected with the front side wall of t...

Embodiment 3

[0072] Such as Figure 10 As shown, the preparation method of an environmentally friendly flame retardant conductive foam is prepared by using a preparation device for an environmentally friendly flame retardant conductive foam as provided in the second embodiment: the detailed preparation steps are as follows:

[0073] S1. Use the digital control spring preparation component 11 to wind a layer of memory alloy metal wire on the conductive foam inner core 1 to form a helical spring, so that the helical spring is pre-compressed on the conductive foam inner core 1;

[0074] S2. If Figure 9 As shown, by energizing and heating the spring at a distance from the right end of the conductive foam inner core 1 to the center L of the conductive foam inner core 1, while using the second manipulator 16 to straighten the energized spring; 1. The spring at a distance L from the left end to the center of the conductive foam inner core 1 is energized and heated, and the second manipulator 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com