Method for preparing soil conditioner for passivating soil heavy metals by taking phosphogypsum as raw material

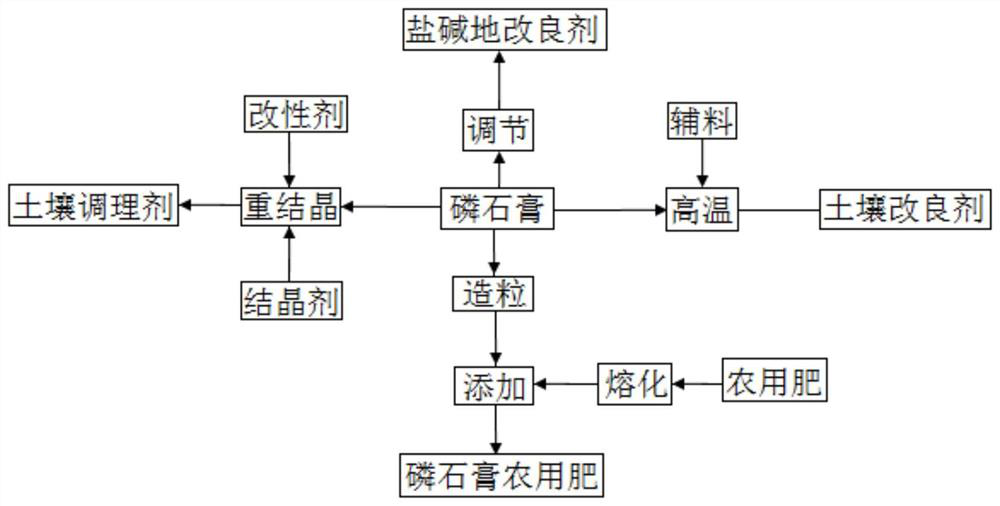

A technology of soil conditioner and phosphogypsum, which is applied in the direction of soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problems of low resource utilization rate of phosphogypsum, heavy burden of solid waste treatment, etc., and achieve the passivation performance of heavy metals , reduce production burden, improve the effect of conditioning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

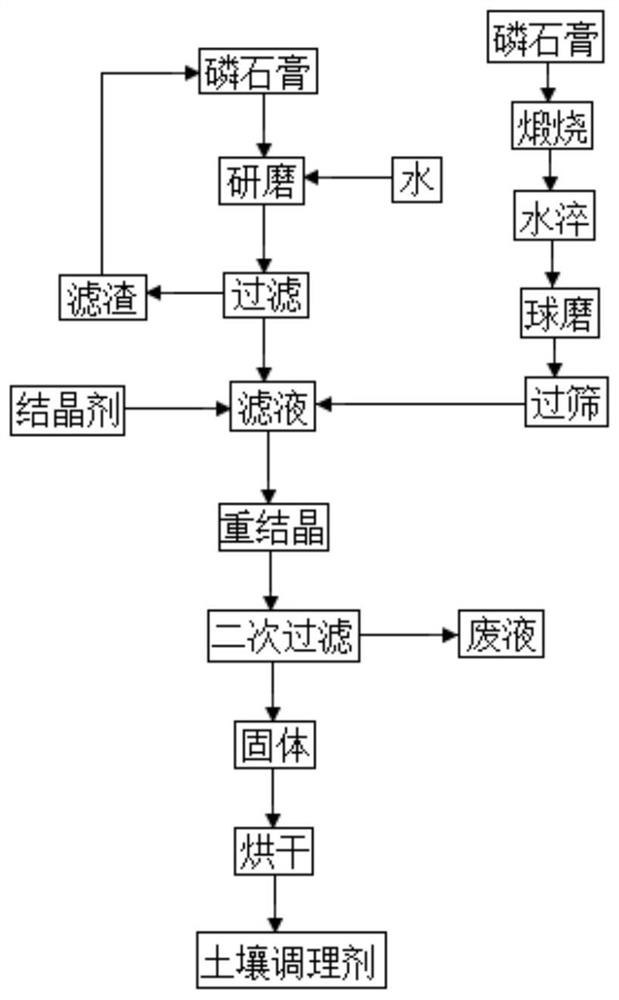

[0025] Such as figure 2 Shown, the soil conditioner preparation process of passivating soil heavy metals, the preparation steps are as follows:

[0026] Preparation of modifier: Calcining phosphogypsum at a temperature of 300°C for 30 minutes under a nitrogen atmosphere, then spraying water while stirring at a stirring speed of 200r / min, the amount of water sprayed accounted for 5% of the mass of phosphogypsum, and sent it into a ball mill Ball milling and passing through a 100-mesh sieve;

[0027] Soil conditioner preparation: take phosphogypsum, grind it with water according to the liquid-solid mass ratio of 5:1, filter it with a 300-mesh screen, return the sieve material (filter residue) and mix it with phosphogypsum to obtain the filtrate (serum); Add nanometer calcium sulfate as crystallization agent and modifying agent, the liquid-solid mass ratio between filtrate and crystallization agent, modifying agent is 100:0.1:5, with 1000r / min stirring speed stirring treatment ...

Embodiment 2

[0029] When preparing the soil conditioner, phosphogypsum and water are mixed and ground according to the liquid-solid mass ratio of 3:1; the liquid-solid mass ratio between the filtrate and the crystallization agent and modifier is mixed at 100:0.4:8, and other treatments refer to the examples 1 for processing and preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com