Hyperbranched epoxy oligosiloxane sand-fixing material as well as preparation method and application thereof

A technology of oligosiloxane and propyltrimethoxysilane, which is applied in the field of hyperbranched epoxy oligosiloxane sand-fixing materials and its preparation, to achieve the effect of not easy to decrease the overall strength, uniform mechanical strength and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

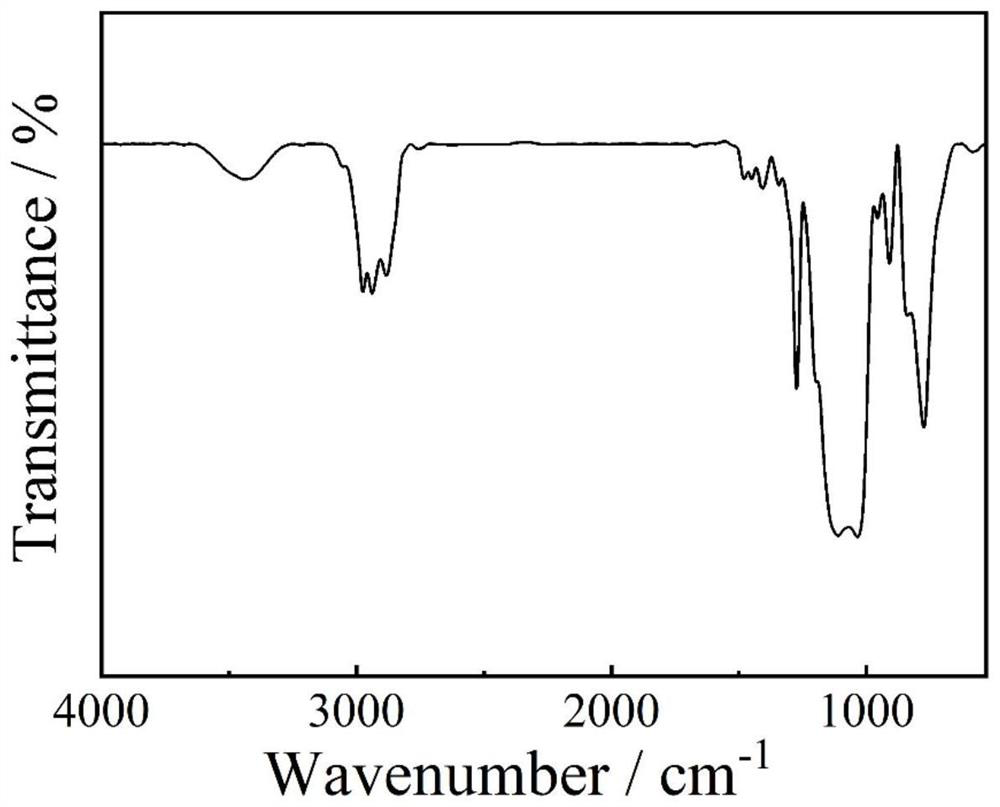

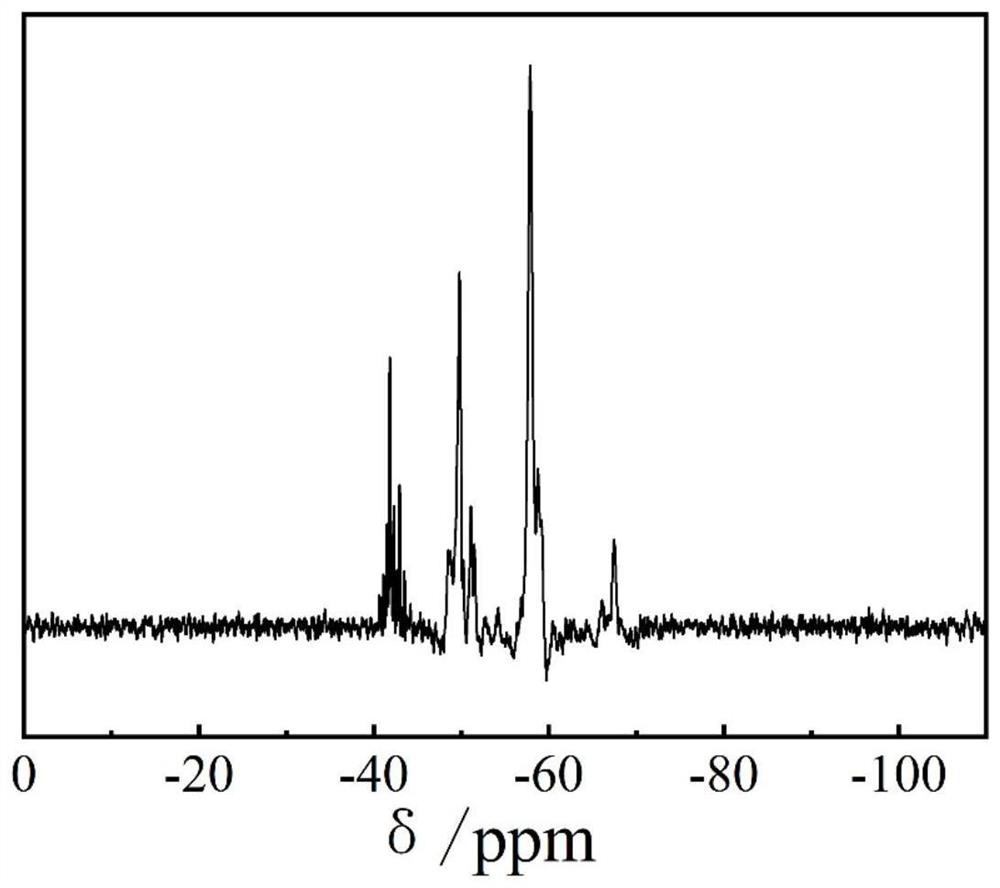

Method used

Image

Examples

Embodiment 1

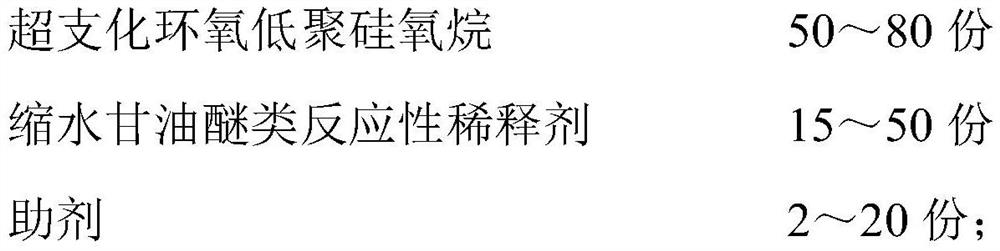

[0045]Add 77 parts of tetramethyl silicate, 23 parts of γ-glycidyl etheroxypropyl trimethoxysilane, 10 parts of absolute ethanol, 5 parts of deionized water, and 1 part of concentrated hydrochloric acid (mass fraction 36-38%) Heating and stirring at 50°C in the reaction kettle for 6 hours, and distilling off hydrochloric acid, ethanol and water in the system under reduced pressure at 80°C to obtain hyperbranched epoxy oligosiloxane. 78 parts by weight of hyperbranched epoxy oligosiloxane, 20 parts of neopentyl glycol diglycidyl ether reactive diluent, 1 part of γ-glycidyl ether oxypropyltrimethoxysilane, 1 part of polyamide wax Mix evenly to obtain component A; 80 parts by weight of diethylenetriamine, 2 parts of phenalkamine T31, 10 parts by weight of 1-methylimidazole, 8 parts by weight of 2,4,6-tris(dimethylaminomethyl Base) phenol is mixed evenly to obtain B component. When in use, stir and mix components A and B at a weight ratio of 100:10 to obtain a hyperbranched epoxy...

Embodiment 2

[0047] 34 parts of methyltrimethoxysilane, 33 parts of diphenyldimethoxysilane, 33 parts of γ-glycidyl etheroxypropyl trimethoxysilane, 30 parts of absolute ethanol, 5 parts of deionized water, 1.5 Parts of concentrated hydrochloric acid (mass fraction 36-38%) were added to the reaction kettle and heated and stirred at 60°C for 6 hours, and hydrochloric acid, ethanol and water in the system were removed by distillation under reduced pressure at 80°C to obtain hyperbranched epoxy oligosiloxane. Mix 60 parts by weight of hyperbranched epoxy oligosiloxane, 38 parts of butyl glycidyl ether reactive diluent, 1 part of γ-methacryloxypropyl trimethoxysilane, and 1 part of polyamide wax Obtain component A uniformly; mix 80 parts by weight of diethylenetriamine, 10 parts by weight of phenalkamine T31, and 10 parts by weight of 1-methylimidazole to obtain component B. When in use, stir and mix components A and B at a weight ratio of 100:15 to obtain a hyperbranched epoxy oligosiloxane s...

Embodiment 3

[0049] 20 parts by weight of methyltrimethoxysilane, 40 parts of diphenyldimethoxysilane, 40 parts of γ-glycidyl etheroxypropyl trimethoxysilane, 20 parts of absolute ethanol, 5 parts of deionized water, Add 1.5 parts of concentrated hydrochloric acid (mass fraction 36-38%) into the reaction kettle, heat and stir at 80°C for 8 hours, and distill under reduced pressure at 70°C to remove hydrochloric acid, ethanol and water in the system to obtain hyperbranched epoxy oligosiloxane. Mix 70 parts by weight of hyperbranched epoxy oligosiloxane, 28 parts of 1,4-butanediol diglycidyl ether, 1 part of γ-glycidyl ether oxypropyltrimethoxysilane, and 1 part of polyamide wax Obtain component A uniformly; 80 parts by weight of 4,4'-diaminodiphenylmethane, 2 parts of polyamide 651, 10 parts of 2-methyl-4-ethylimidazole, 8 parts by weight of triethylamine Mix well to obtain B component. When in use, stir and mix components A and B at a weight ratio of 100:20 to obtain a hyperbranched epoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com