Preparation method of nitrogen-doped mesoporous carbon loaded high-dispersion Ru nanoparticle catalyst and application thereof

A nitrogen-doped mesoporous carbon and nanoparticle technology, applied in electrolysis components, electrodes, electrolysis process, etc., can solve problems such as poor catalytic activity at high current, high production cost, and limit large-scale practical application, and achieve a higher atomic efficiency. Utilization rate, ensure effective utilization, and the effect of excellent catalytic hydrogen evolution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

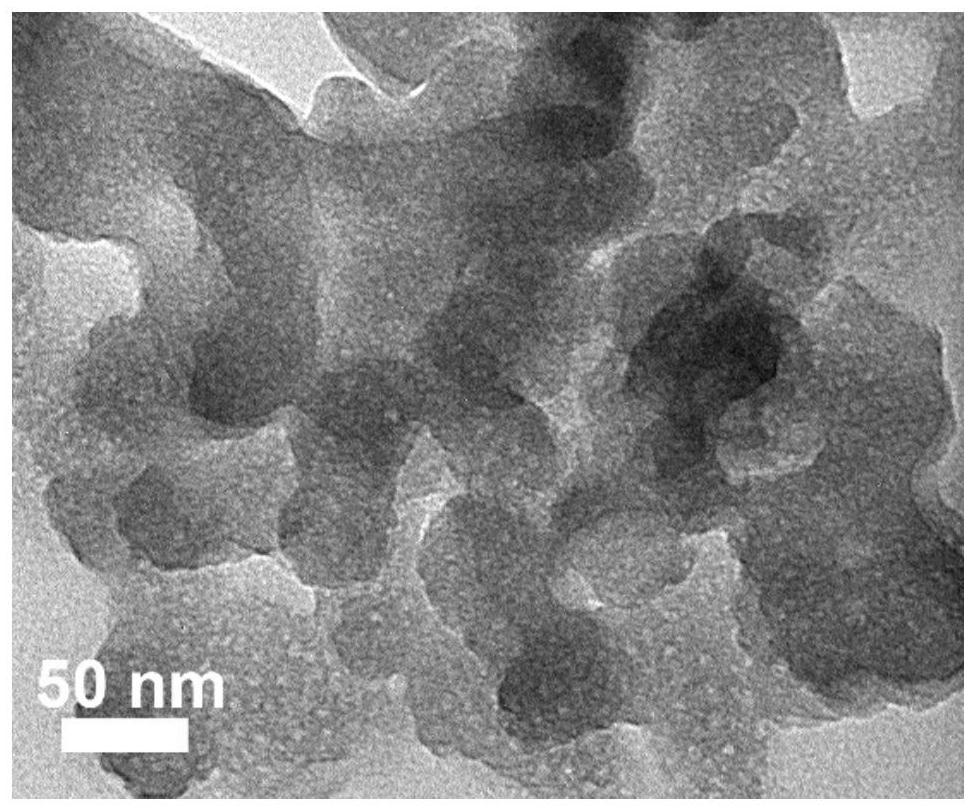

[0043] Embodiment 1, the preparation of nitrogen-doped mesoporous carbon nanomaterial (NMC)

[0044] In order to compare the performance difference between the nitrogen-doped mesoporous carbon electrolysis hydrogen evolution catalyst without Ru nanoclusters and the low-cost nitrogen-doped mesoporous carbon supported highly dispersed Ru nanoparticles catalyst, a nitrogen-doped mesoporous carbon nanomaterials.

[0045] Concrete preparation method comprises the following steps:

[0046] (a) Preparation of precursor solution: Dissolve 0.470g F127 in 5mL deionized water, stir well to obtain uniform solution A; add 0.421g 3-aminophenol to 75mL deionized water, stir well to obtain solution B; 0.654g of hexamethylenetetramine, continue to fully stir until uniformly recorded as solution C. Add solution A to mixed solution C, place in an oil bath, heat and stir at 50°C for 16 hours to obtain prepolymerized solution D;

[0047] (b) Preparation of nitrogen-doped mesoporous polymer prec...

Embodiment 2

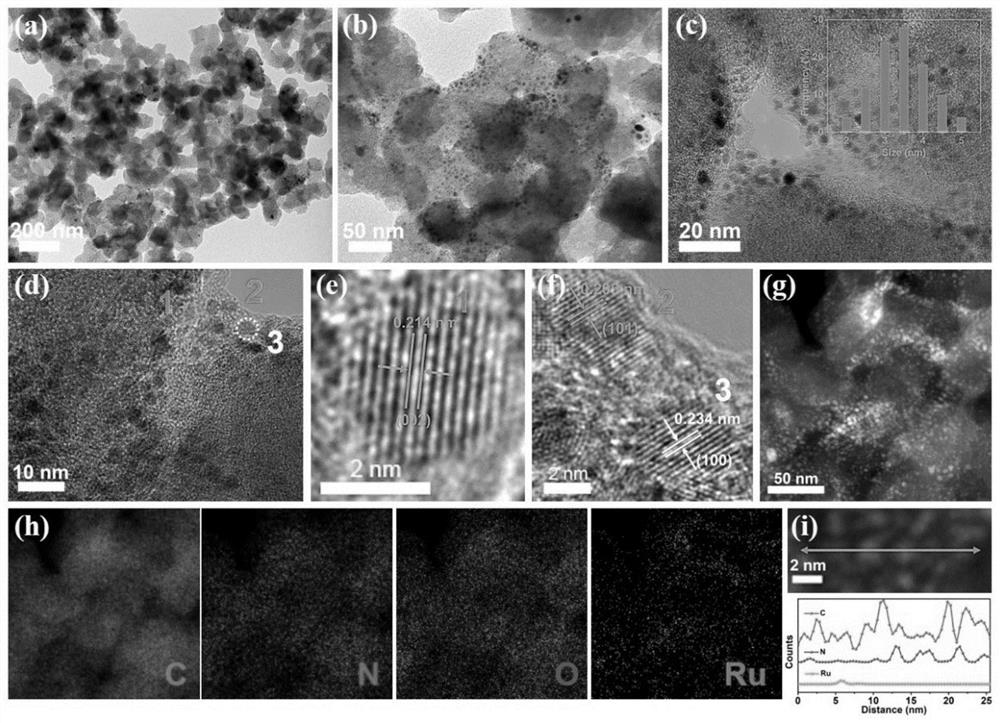

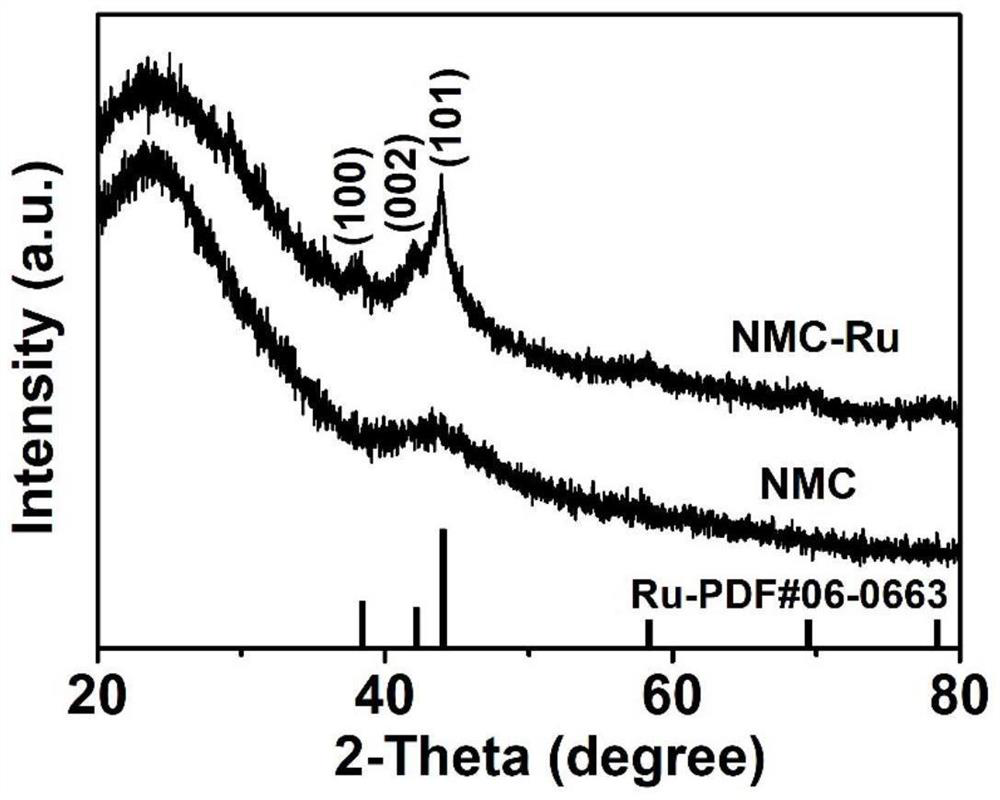

[0050] Embodiment 2, preparation of nitrogen-doped mesoporous carbon-supported highly dispersed Ru nanoparticle catalyst (NMC-Ru):

[0051] (a) Preparation of precursor solution: Dissolve 0.470g F127 in 5mL deionized water, stir well to obtain uniform solution A; add 0.421g 3-aminophenol to 75mL deionized water, and stir uniformly to obtain solution B; Add 0.654g of hexamethylenetetramine, and continue to stir well until it is homogeneously recorded as solution C. Add solution A to mixed solution C, place in an oil bath, heat and stir at 50°C for 16 hours to obtain prepolymerized solution D;

[0052] (b) Preparation of nitrogen-doped mesoporous polymer precursor: transfer the solution D into a polytetrafluoroethylene reactor and place it in an oven, raise the temperature from room temperature to 130 °C at a rate of 1 °C / min, and carry out water After 8 hours of thermal reaction, the reaction kettle was naturally cooled to room temperature with an oven to obtain a gel-like pro...

Embodiment 3

[0058] Example 3, Preparation of nitrogen-doped mesoporous carbon-supported highly dispersed CoRu nanoparticle catalyst (NMC-CoRu)

[0059] A method for preparing a nitrogen-doped mesoporous carbon-supported highly dispersed CoRu nanoparticle catalyst, comprising the steps of:

[0060] (a) Preparation of precursor solution: Dissolve 0.470g F127 in 5mL deionized water, stir well to obtain uniform solution A; add 0.421g 3-aminophenol to 75mL deionized water, stir well to obtain solution B; 0.654g of hexamethylenetetramine, continue to fully stir until uniformly recorded as solution C. Add solution A to mixed solution C, place in an oil bath, heat and stir at 50°C for 16 hours to obtain prepolymerized solution D;

[0061] (b) Preparation of nitrogen-doped mesoporous polymer precursor: transfer the solution D into a polytetrafluoroethylene reactor and place it in an oven, raise the temperature from room temperature to 130 °C at a rate of 1 °C / min, and carry out water After 8 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com