Preparation method of all-silicon molecular sieve encapsulated nano-silver bactericide

A technology of all-silicon molecular sieve and nano-silver, applied in botany equipment and methods, biocides, disinfectants, etc., can solve the problems of fast release rate of Ag bactericide, uneven distribution of Ag, affecting bactericidal performance, etc., to avoid aggregation , avoid violent release phenomenon, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

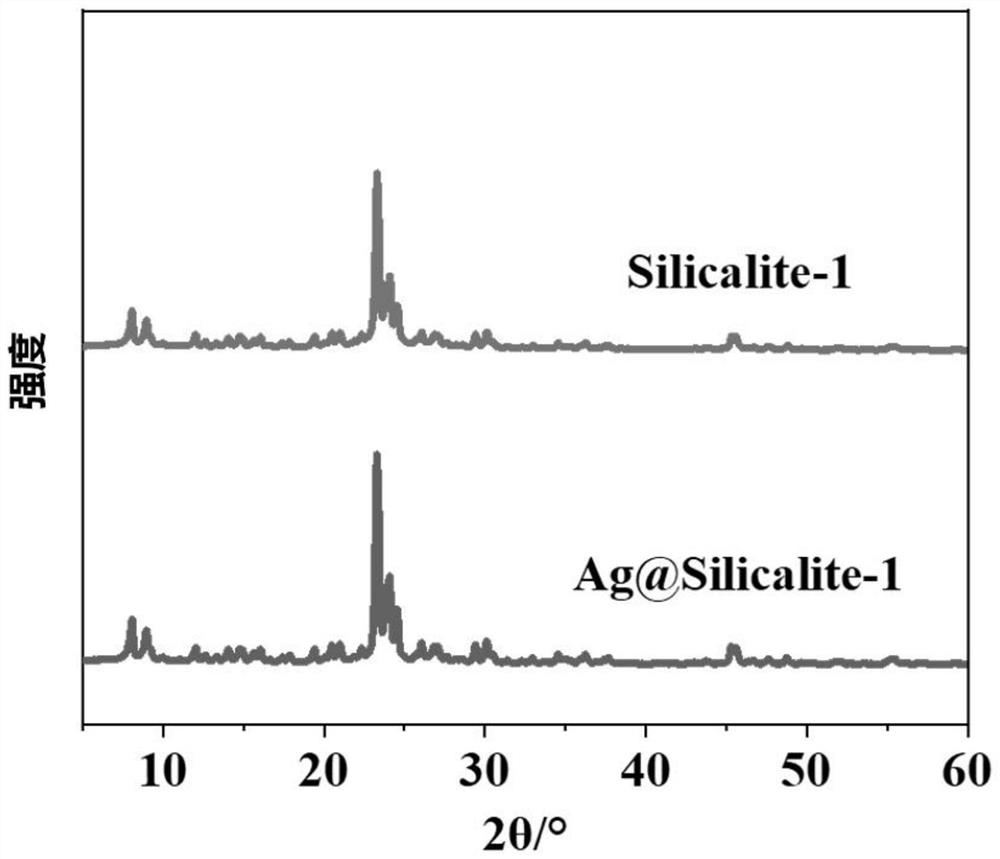

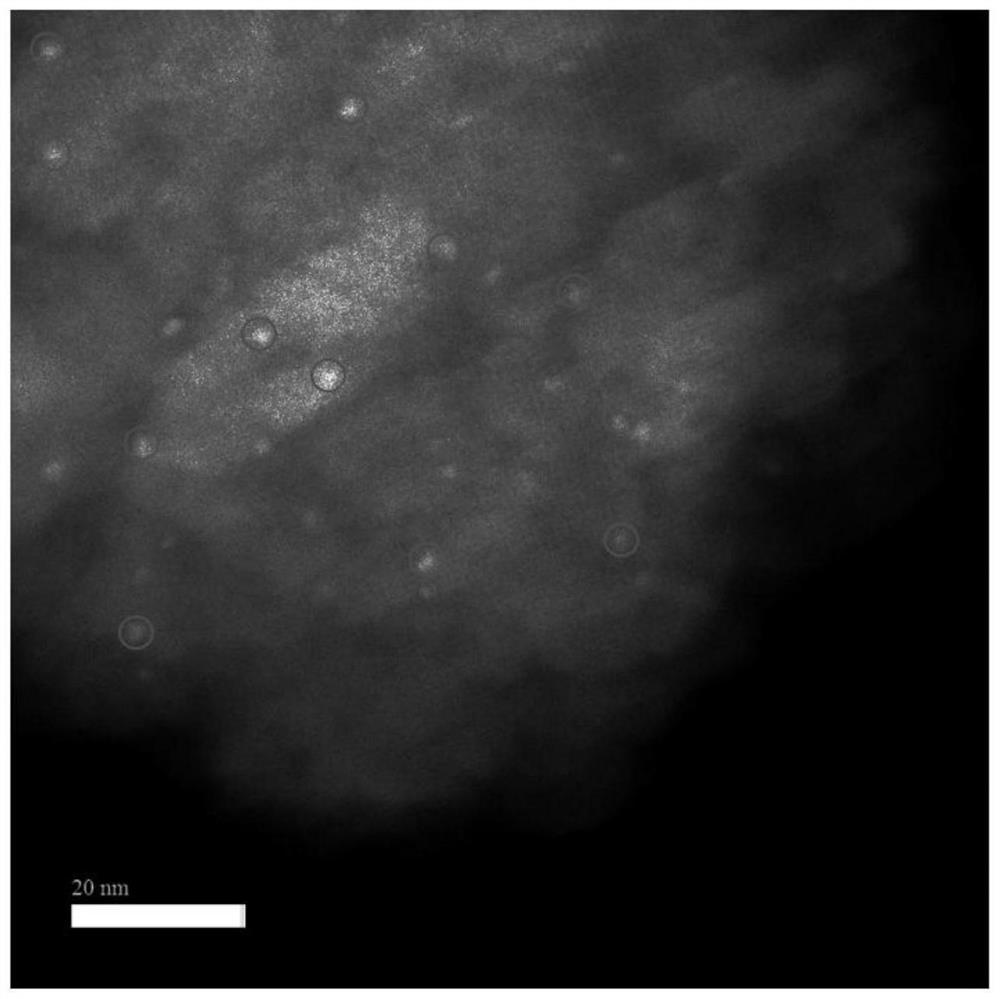

[0027] Embodiment 1 A kind of preparation method of all-silicon molecular sieve encapsulation nano-silver fungicide (using Silicalite-1 molecular sieve as molecular sieve carrier)

[0028] (1) Get 7.32g tetrapropyl ammonium hydroxide aqueous solution (TPAOH, 40wt%), add 5g H 2 Dilute with O, then add 0.507mL (3-mercaptopropyl) trimethoxysilane, mix well to make a mixed solution; take 0.022g silver nitrate (AgNO 3 ), plus 7.887gH 2 O was dissolved into an aqueous silver nitrate solution, and the obtained aqueous silver nitrate solution was added dropwise to the above mixed solution, and the stirring was continued for 30 minutes.

[0029] (2) Add 10g of tetraethyl silicate (TEOS) dropwise to the above mixing system, mix evenly to obtain a colorless and transparent silver-silica sol, heat the obtained silver-silica sol to 80°C, stir and age for 1h, and obtain silver -Silicone gel.

[0030] (3) Put the above silver-silica gel into a polytetrafluoroethylene-lined crystallization...

Embodiment 2

[0032] Embodiment 2 A kind of preparation method of all-silicon molecular sieve encapsulated nano-silver fungicide

[0033] (1) Get 7.32g tetrapropyl ammonium hydroxide aqueous solution (TPAOH, 40wt%), add 5g H 2 O to dilute, then add 0.622mL (3-mercaptopropyl) trimethoxysilane, mix well to make a mixed solution; take 0.027g silver nitrate (AgNO 3 ), add 7.887g H 2 O was dissolved into an aqueous silver nitrate solution, and the obtained aqueous silver nitrate solution was added dropwise to the above mixed solution, and the stirring was continued for 30 minutes.

[0034] (2) Add 10g of tetraethyl silicate (TEOS) dropwise to the above mixing system, mix evenly to obtain a colorless and transparent silver-silica sol, heat the obtained silver-silica sol to 80°C, stir and age for 1h, and obtain silver -Silicone gel.

[0035] (3) Put the above silver-silica gel into a polytetrafluoroethylene-lined crystallization kettle for static crystallization at 95°C for 4 days, centrifuge, ...

Embodiment 3

[0037] Embodiment 3 A kind of preparation method of all-silicon molecular sieve encapsulated nano-silver fungicide

[0038](1) Get 7.32g tetrapropyl ammonium hydroxide aqueous solution (TPAOH, 40wt%), add 5g H 2 O to dilute, then add 0.761mL (3-mercaptopropyl) trimethoxysilane, mix well to make a mixed solution; take 0.033g silver nitrate (AgNO 3 ), add 7.887g H 2 O was dissolved into an aqueous silver nitrate solution, and the obtained aqueous silver nitrate solution was added dropwise to the above mixed solution, and the stirring was continued for 30 minutes.

[0039] (2) Add 10g of tetraethyl silicate (TEOS) dropwise to the above mixing system, mix evenly to obtain a colorless and transparent silver-silica sol, heat the obtained silver-silica sol to 80°C, stir and age for 1h, and obtain silver -Silicone gel.

[0040] (3) Put the above silver-silica gel into a polytetrafluoroethylene-lined crystallization kettle for static crystallization at 95°C for 4 days, centrifuge, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com