Positioning clamp for rotary polishing of R face of sliding vane of compressor and polishing method for rotary polishing of R face of sliding vane of compressor

A compressor and sliding vane technology, which is applied to the positioning fixture and polishing field of rotary polishing of the R surface of the compressor sliding vane, can solve the problems of only 0.4μm surface roughness, metal dust pollution, and reduce polishing efficiency, and achieve improved Polishing accuracy, ensuring stable grinding, and improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The compressor sliding vane is made of high-speed steel with carburized gas surface, the original hardness is 60HRC, the original roughness Ra is 2.8μm, and the machining allowance is ≤5μm.

[0035] 1) Evaluate the original roughness of the R surface of the compressor slide vane carburized in the gas surface layer to be 2.8 μm.

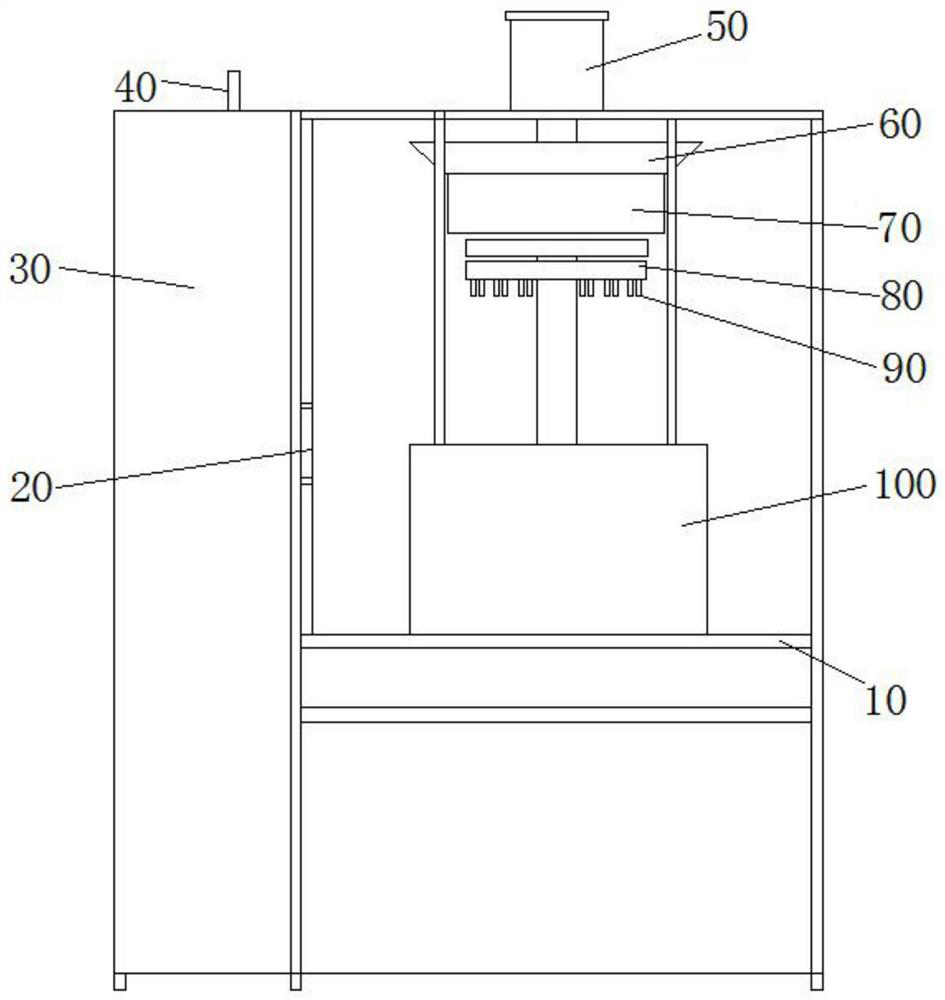

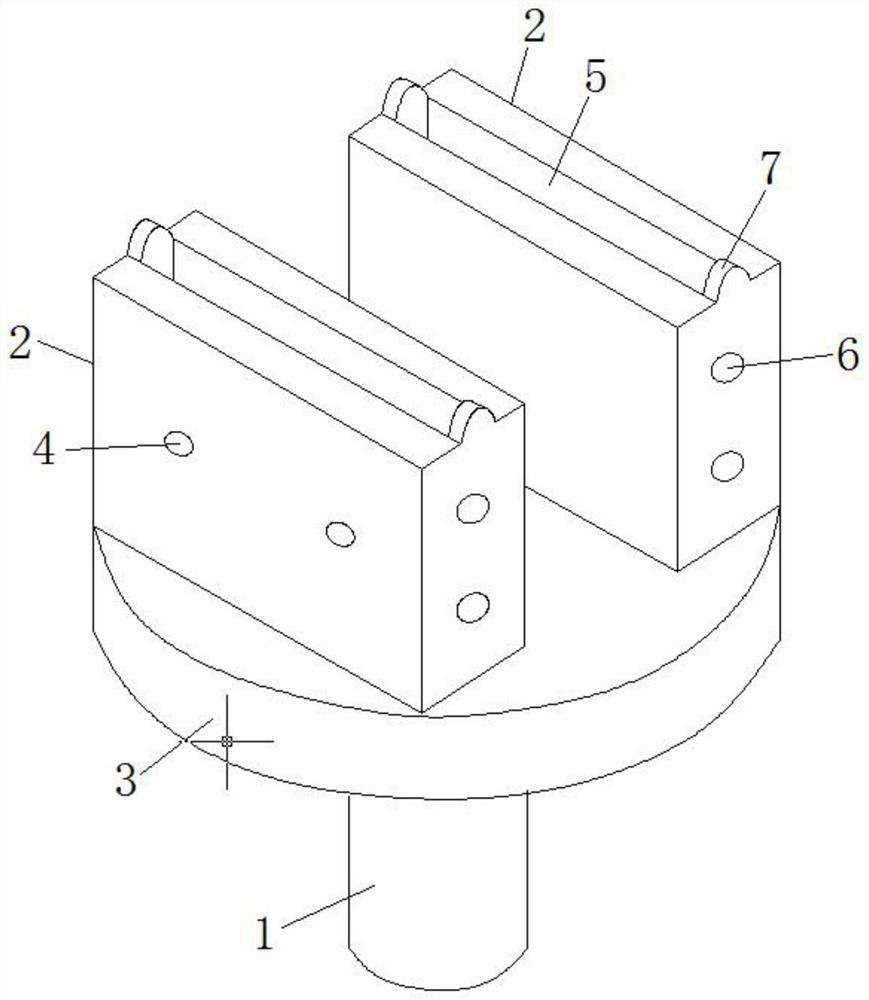

[0036] 2) Install the compressor slide in the fixture, such as figure 2 .

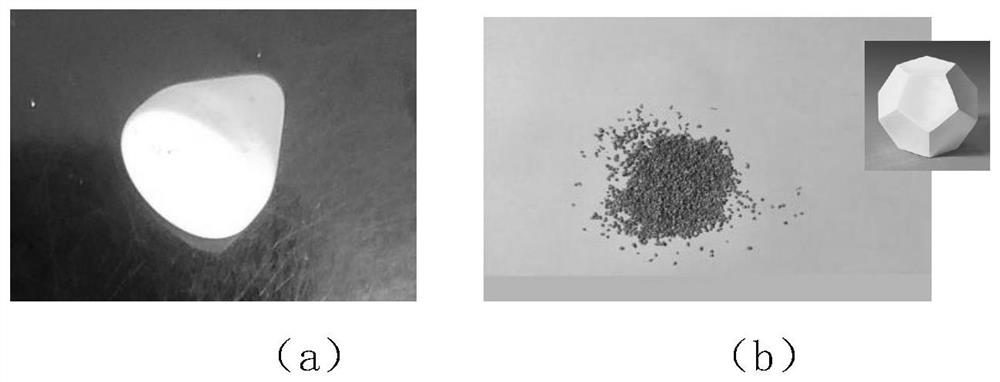

[0037] 3) Select the abrasive B for precision polishing according to the original roughness, such as image 3 (b), the abrasive B is corn kernels: chromium oxide: corundum according to the mass ratio of (90-100): (2-5): (30-40), the D50 of the abrasive B is 100 microns, The structure is a topological polyhedron, each angle of the topological polyhedron ranges from 15° to 160°, and the processing time is 30 minutes to obtain a polished slide, such as Figure 4 .

[0038] 4) After polishing, the roughness of the R surface of the compressor sliding vane is less than 0...

Embodiment 2

[0040] The compressor slide is made of carbonitrided high-speed steel on the gas surface. The original hardness is 60HRC, the original roughness Ra is 12μm, and the machining allowance is ≤5μm. It is required that the roughness Ra of the R surface of the slide must be less than 0.05μm.

[0041] 1) Evaluation The original roughness of the R surface of the compressor slide vane carburized by the gas surface is 12 μm.

[0042] 2) Install the compressor slide in the fixture.

[0043] 3) According to the original roughness, select the grinding material A and add water and grinding liquid. The grinding material A includes: A abrasive grains, water, and grinding liquid. The volume ratio of the A grinding grains to water is 6-8:1. The grinding The ratio of liquid to water added is 2 to 5:100, the hardness of the A abrasive grain is greater than 2000HV, and the shape and structure are conical, and the A abrasive grain is green silicon carbide: brown corundum: plastic grinding according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com