Equipment for preparing polylactic acid blank

A polylactic acid and embryo material technology is applied in the field of equipment for preparing polylactic acid embryo material, which can solve the problems of inability to manufacture internal fixation devices for fractures, low mechanical properties of polylactic acid, unsatisfactory bending strength and impact strength, etc., to simplify equipment. The effect of structure and work flow, good mechanical properties, and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

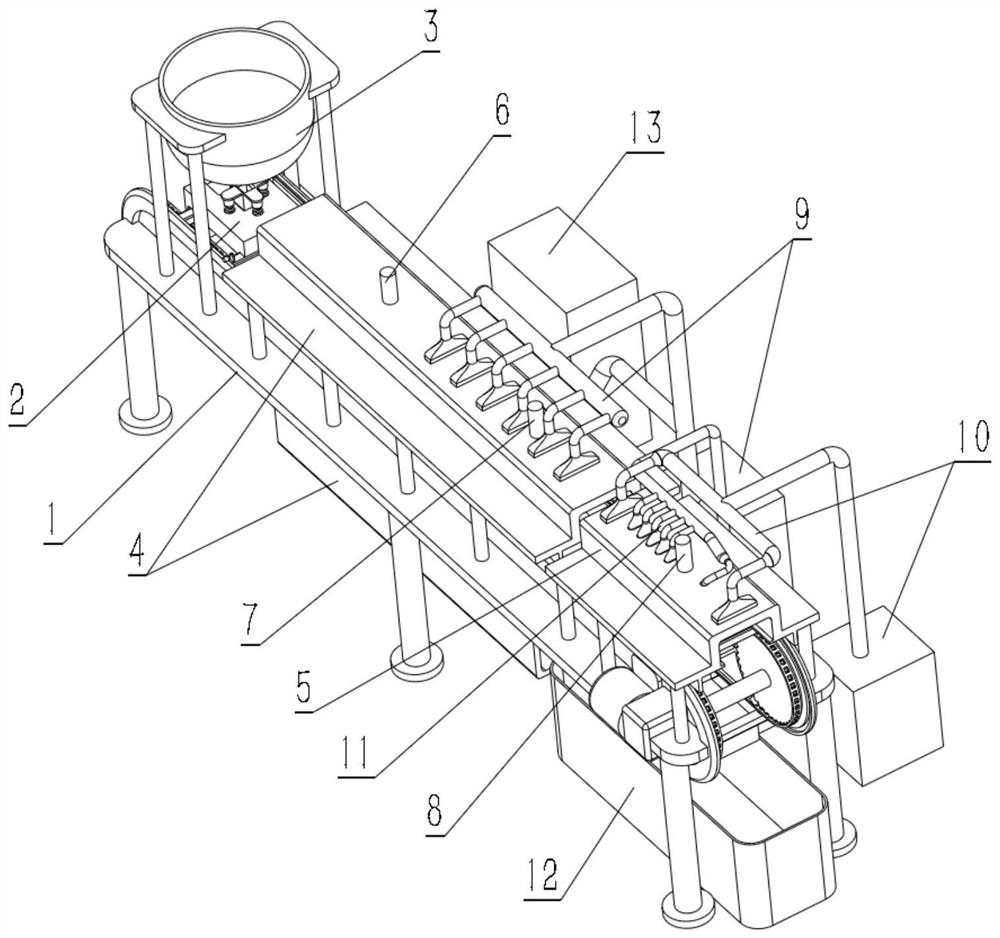

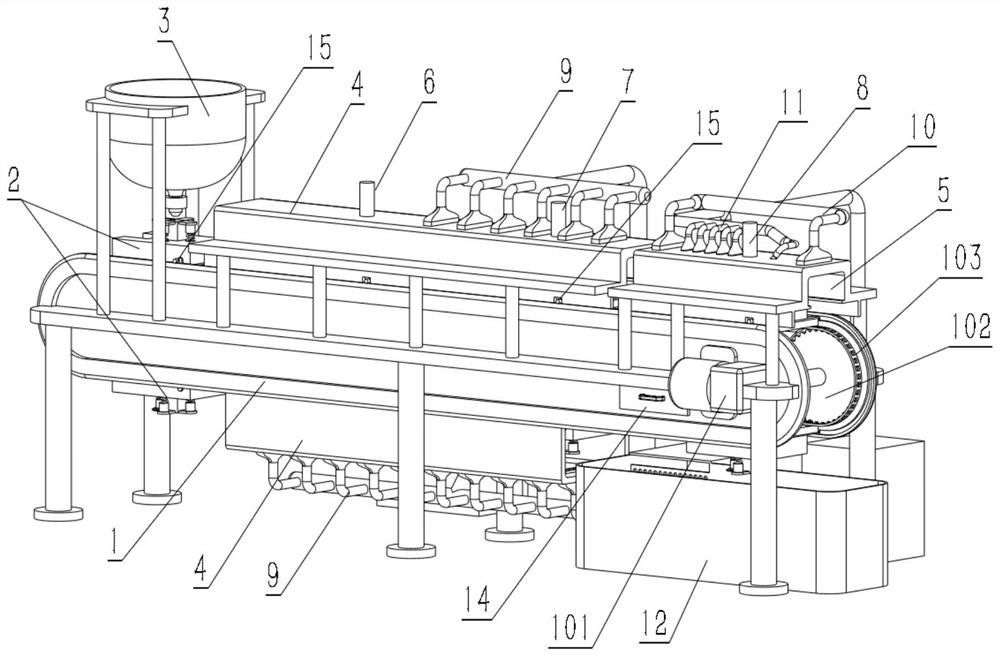

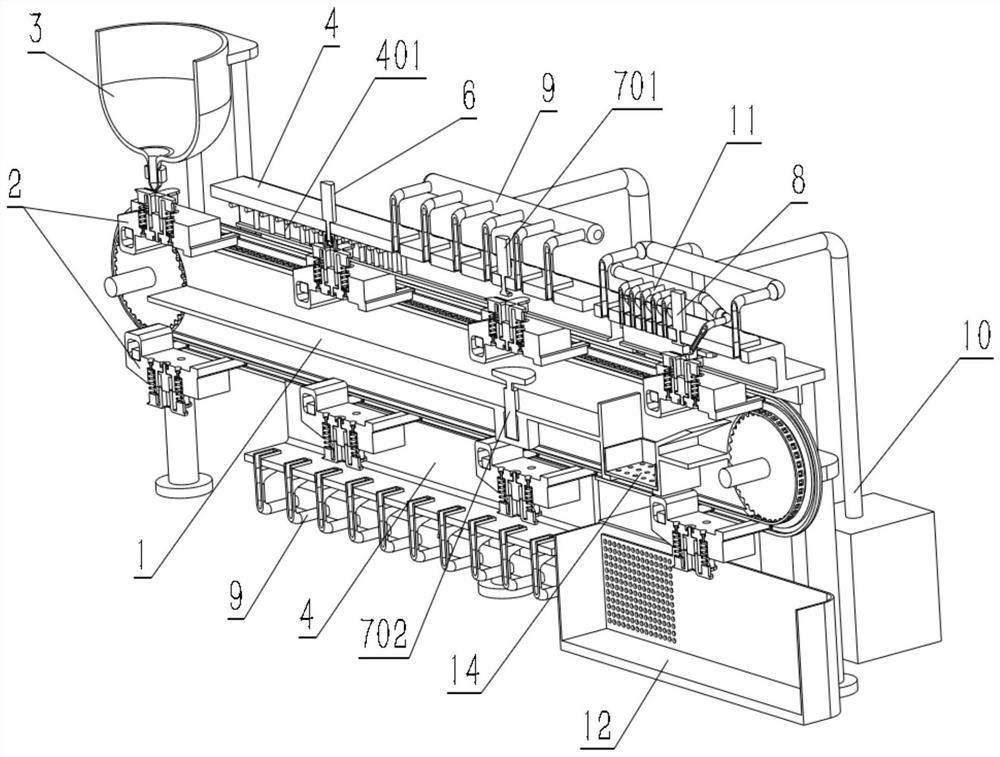

[0028] Such as Figure 1 to Figure 11 As shown, a kind of equipment for preparing polylactic acid blank material according to the present invention adopts the technical scheme of adopting a transmission device 1 with a chain transmission structure, and the transmission device 1 drives the sprocket 102 to rotate through the drive motor 101, and the transmission on the sprocket 102 cooperates with Two chains 103 are installed, and the chains 103 are located on both sides of the conveying device 1, and the two sides of the conveying device 1 are provided with positioning chute 105 at equidistant positions on the outer circle of the chains 103, and the chains 103 are fixedly connected with the embryo pressing workbench 2 at equal intervals, The embossing table 2 slides and buckles in the positioning chute 105 and can be driven circularly with the chain 103. The conveying device 1 is divided into four stations from left to right, and each station corresponds to the top position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com