Waterproof self-repairing building material and preparation method thereof

A self-healing and building material technology, applied in the field of concrete self-repairing, can solve the problems of consumption of osmotic crystallization, damage, and difficulty in dissolving the polymer film, and achieves the effects of simple preparation method, improved overall life, and reduced maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

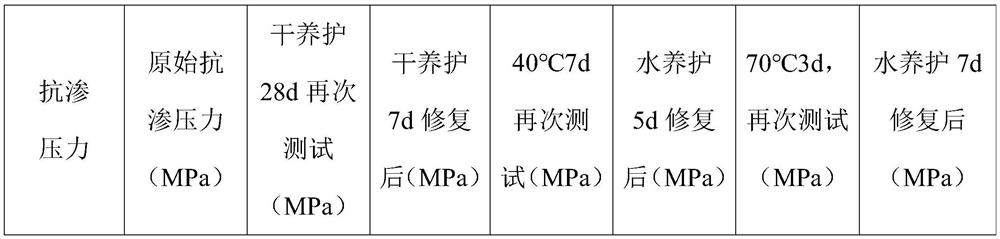

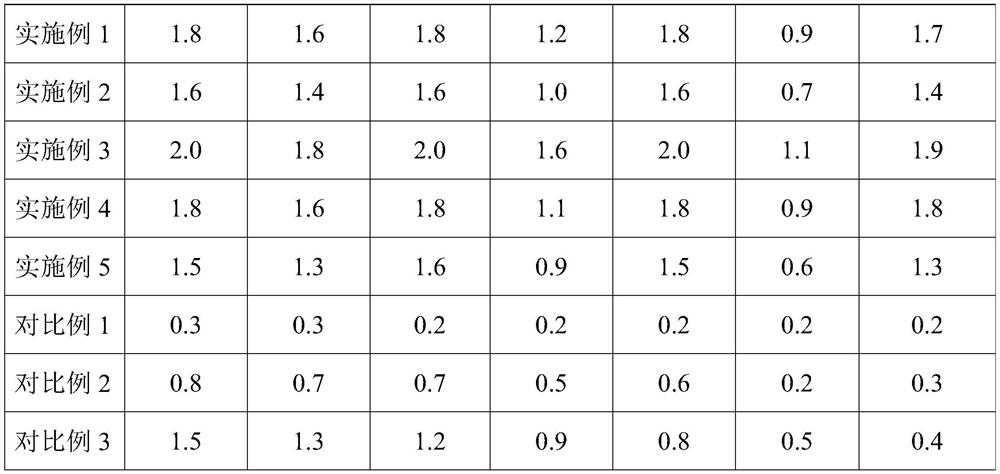

Examples

Embodiment 1

[0042] (1) Stir and mix 18g crotonic acid and 54g water evenly, add 13g magnesium hydroxide and 6g calcium hydroxide while stirring, the pH value of the mixed solution obtained after the reaction is 10, and then add 1.2g N,N-methylene Based on bisacrylamide, the self-healing agent was obtained after standing and filtering.

[0043] (2) 30g self-healing agent described in step (1) is mixed with 0.7g potassium persulfate and 195g water to obtain a mixed solution;

[0044] (3) Mix the mixed solution obtained in step (2) with 450g Portland cement and 1350g sand evenly to obtain the building material.

Embodiment 2

[0046] (1) Stir and mix 18g crotonic acid and 54g water evenly, add 10g magnesium hydroxide and 8g calcium hydroxide while stirring, the pH value of the mixed solution obtained after the reaction is 10, and then add 1.2g N,N-methylene Based on bisacrylamide, the self-healing agent was obtained after standing and filtering.

[0047] (2) 20g self-healing agent described in step (1) is mixed with 0.58g potassium persulfate and 180g water to obtain a mixed solution;

[0048] (3) Mix the mixed solution obtained in step (2) with 420g Portland cement and 1500g sand evenly to obtain the building material.

Embodiment 3

[0050] (1) Stir and mix 7g of acrylic acid, 10g of crotonic acid and 54g of water evenly, add 13g of magnesium hydroxide and 6g of calcium hydroxide while stirring, the pH value of the mixed solution obtained after the reaction is 9, and then add 1g of N,N- Methylenebisacrylamide, the self-healing agent is obtained after standing and filtering.

[0051] (2) 36g self-healing agent described in step (1) is mixed with 0.88g potassium persulfate and 210g water to obtain a mixed solution;

[0052] (3) Mix the mixed solution obtained in step (2) with 480g Portland cement and 1200g sand evenly to obtain the building material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com