Low-temperature Fischer-Tropsch synthesis iron-based catalyst reduction method

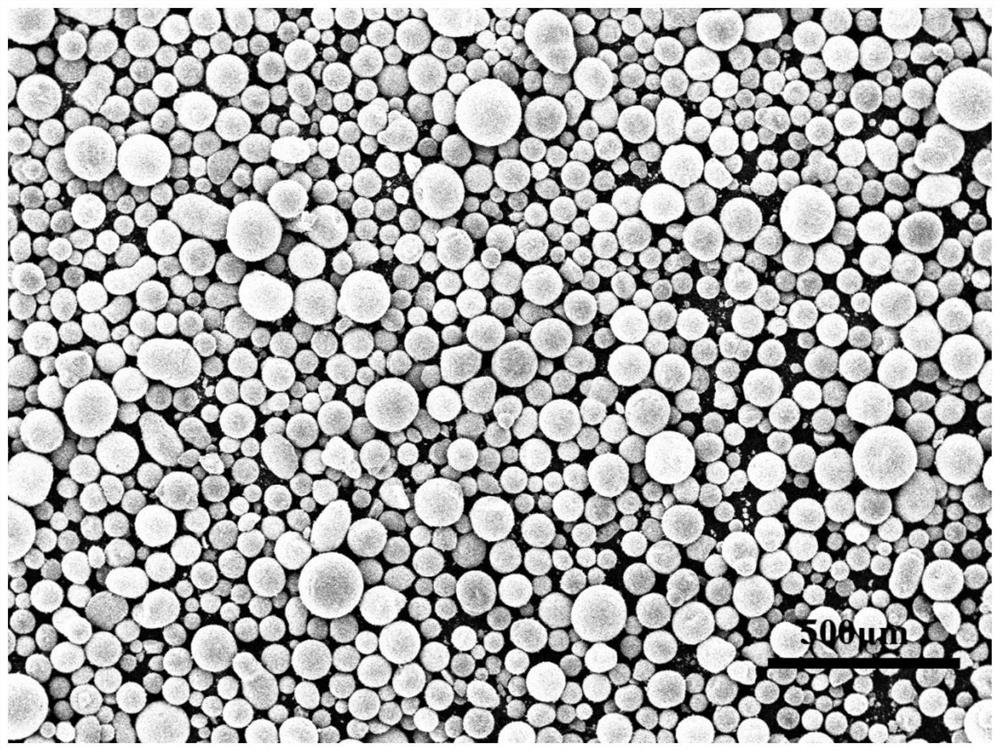

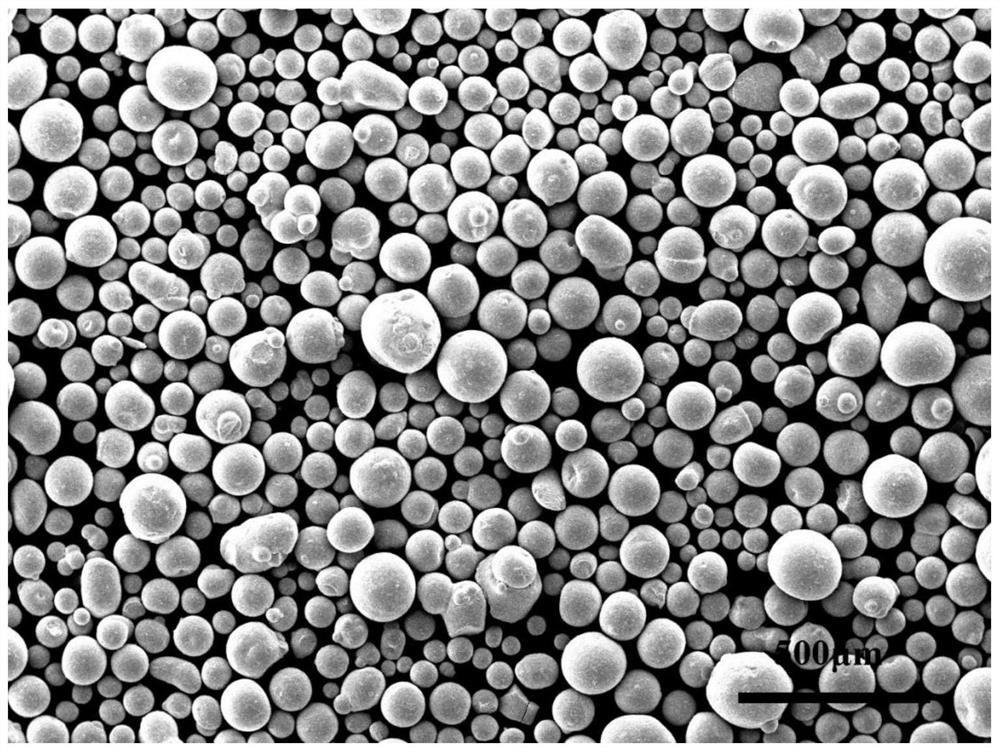

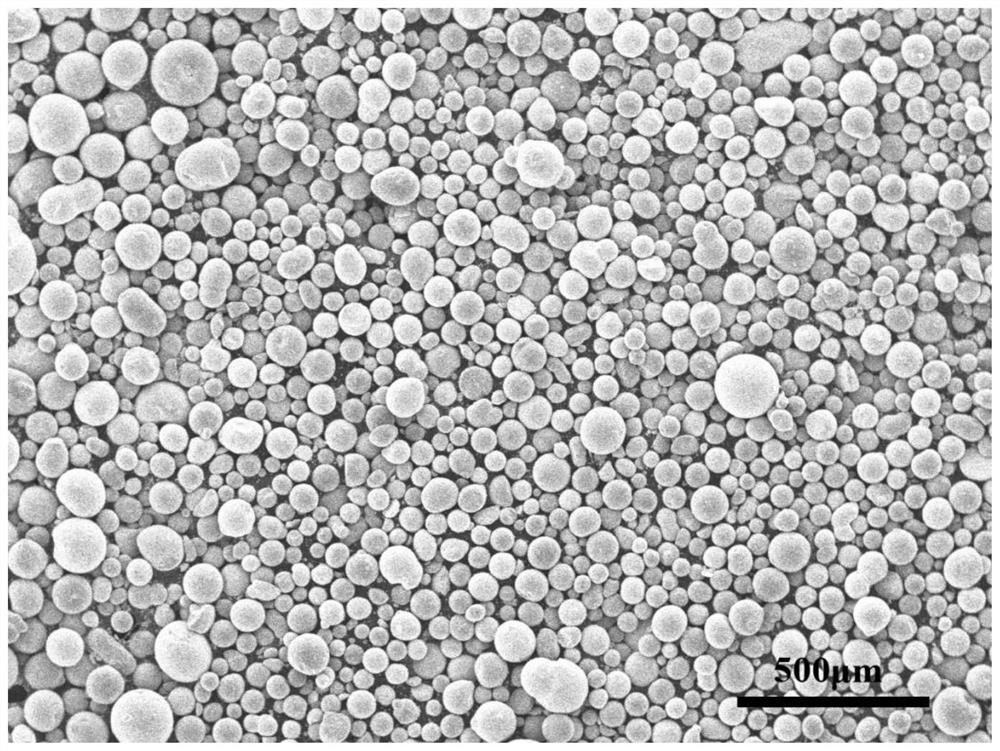

An iron-based catalyst, Fischer-Tropsch synthesis technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., to achieve the effects of good reduction effect, improved selectivity and complete sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add the mixed slurry with a solid content of 28% catalyst and liquid paraffin (preheated to 180°C, fed by nitrogen pressure) into a nitrogen-filled slurry bed reactor (the empty reactor is preheated to 180°C by an electric heater) , continuously feed fresh reducing gas into the reactor (the reducing gas is introduced from the water gas production site, and is purified by low-temperature methanol washing, molecular sieve and other processes).

[0032] Reactor heating process: 180°C→200°C, heating rate 3°C / h.

[0033] Catalyst active component reduction stage: the reduction temperature is 200°C, the time is 16h, the pressure is 1.5MPa, and the space velocity is 3500mL(N) / g catalyst / h.

[0034] Catalyst active component activation stage: the activation temperature is 200°C, the time is 19h, the pressure is 1.5MPa, and the space velocity is 4000mL(N) / g catalyst / h.

[0035] The experimental results are as follows:

[0036]

[0037] Compared with the normal reduction sam...

Embodiment 2

[0039] Add the mixed slurry with a solid content of 33% catalyst and liquid paraffin (preheated to 180°C, fed by nitrogen pressure) into the nitrogen-filled slurry bed reactor (the empty reactor is preheated to 180°C by an electric heater) , continuously feed fresh reducing gas into the reactor (the reducing gas is introduced from the water gas production site, and is purified by low-temperature methanol washing, molecular sieve and other processes).

[0040] The heating process of the reactor: 180°C→230°C, the heating rate is 7°C / h.

[0041] Catalyst active component reduction stage: the reduction temperature is 230° C., the time is 13 hours, the pressure is 1.8 MPa, and the space velocity is 4000 mL(N) / g catalyst / h.

[0042] Catalyst active component activation stage: the activation temperature is 230°C, the time is 17h, the pressure is 1.8MPa, and the space velocity is 4300mL(N) / g catalyst / h.

[0043] The experimental results are as follows:

[0044]

[0045] Compared ...

Embodiment 3

[0047]Add the mixed slurry with a solid content of 40% catalyst and liquid paraffin (preheated to 180°C, fed by nitrogen pressure) into the nitrogen-filled slurry bed reactor (the empty reactor is preheated to 180°C by an electric heater) , continuously feed fresh reducing gas into the reactor (the reducing gas is introduced from the water gas production site, and is purified by low-temperature methanol washing, molecular sieve and other processes).

[0048] Reactor heating process: 180°C→240°C, heating rate 9°C / h.

[0049] Catalyst active component reduction stage: the reduction temperature is 240°C, the time is 28h, the pressure is 2.3MPa, and the space velocity is 4500mL(N) / g catalyst / h.

[0050] Catalyst active component activation stage: the activation temperature is 240°C, the time is 24h, the pressure is 2.3MPa, and the space velocity is 4800mL(N) / g catalyst / h.

[0051] The experimental results are as follows:

[0052]

[0053] Compared with the normal reduction sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com