Preparation method of nickel-rich precursor material that can prevent particle breakage

A precursor, nickel-rich technology, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as poor sphericity, particle breakage, and poor cycle performance of high-nickel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

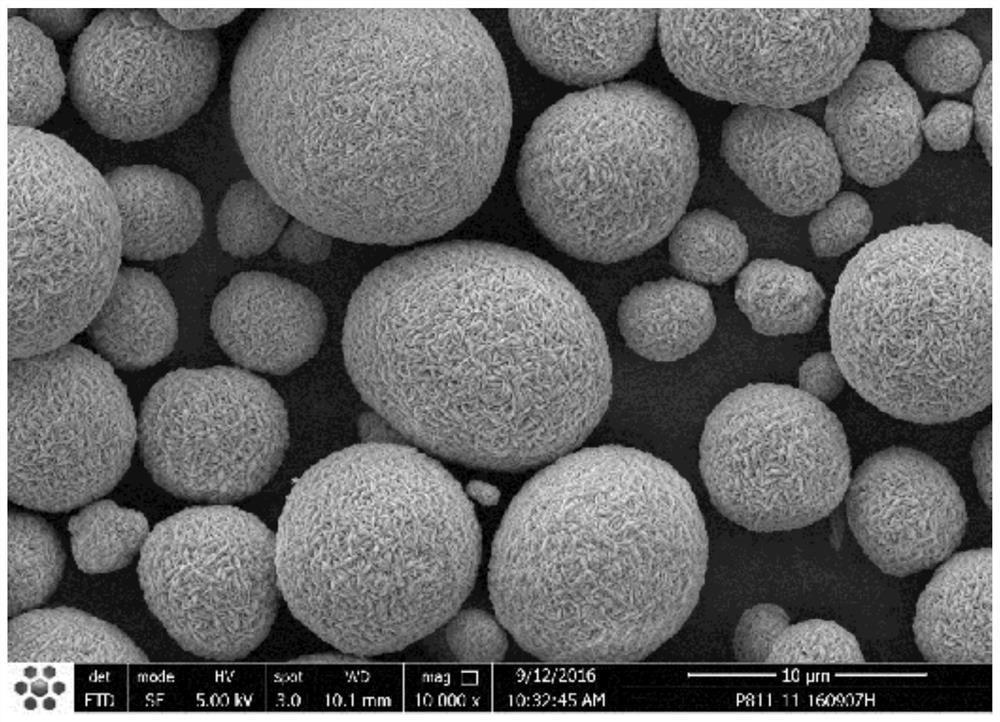

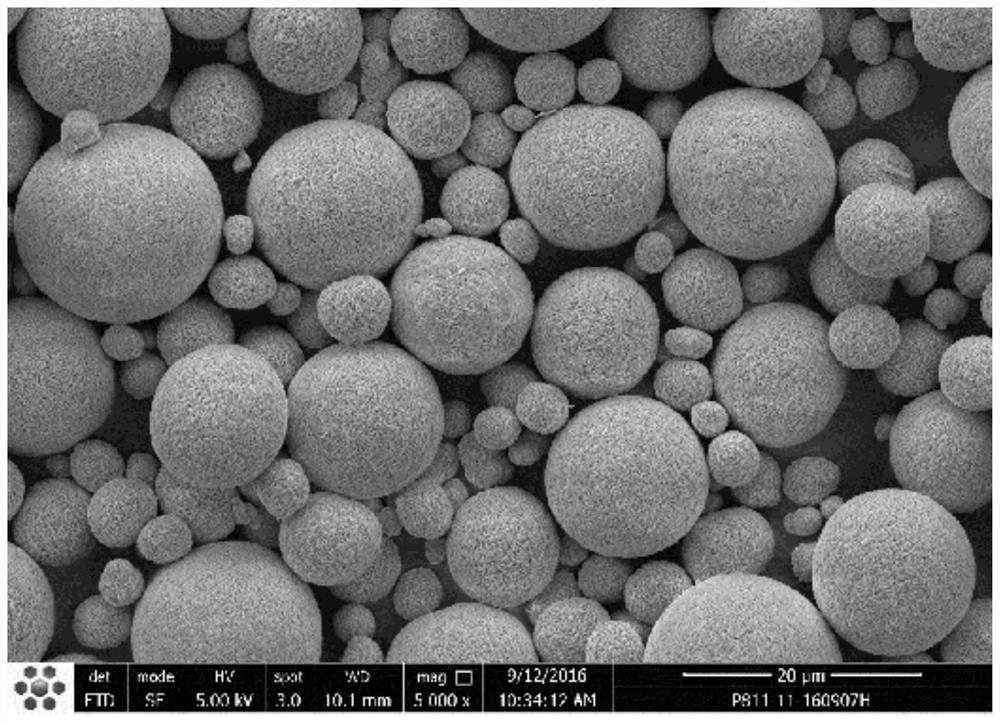

[0044] A Ni-rich-based precursor material that prevents particle cracking x Co y Mn 1-x-y (OH) 2 The preparation method of nickel-rich precursor material Ni x Co y Mn 1-x-y (OH) 2 D 50 The size is set as 9μm≤d≤16μm, and the preparation method specifically includes the following steps:

[0045] (1) According to the Ni-rich precursor material Ni x Co y Mn 1-x-y (OH) 2 In the ratio of metal ions, the mixed metal salt solution of 1-2mol / L, the sodium hydroxide solution of 6-10mol / L and the ammonia water of 10-13mol / L are prepared;

[0046] (2) Ammonia water is pumped into the reaction kettle, so that the ammonia concentration in the reaction kettle bottom liquid is the target ammonia concentration 8-16g / L, and then the pH of the reaction kettle bottom liquid is adjusted to the target pH value=11.6 with sodium hydroxide solution -12, and make the bottom liquid pass the stirring paddle of the reactor;

[0047] (3) Charge nitrogen into the reaction kettle, start stirring...

Embodiment 1

[0059] A kind of nickel-rich-based precursor material Ni capable of preventing particle cracking of the present invention 0.8 Co 0.1 Mn 0.1 (OH) 2 The preparation method of nickel-rich precursor material Ni 0.8 Co 0.1 Mn 0.1 (OH) 2 D 50 The size is set to 10 ± 0.5 μm, and the preparation method specifically includes the following steps:

[0060] (1) According to the molecular formula of Ni-rich precursor material Ni 0.8 Co 0.1 Mn 0.1 (OH) 2 In the ratio of metal ions, the mixed metal salt solution of 2mol / L, the sodium hydroxide solution of 10mol / L and the ammonia water of 13mol / L are prepared;

[0061] (2) pump the ammoniacal liquor of 13mol / l in the reactor, make the ammonia concentration of the bottom liquid of the reactor be the set target ammonia concentration 12-13 g / L, then use the sodium hydroxide solution of 10mol / L to make the reactor The pH of the bottom liquid is adjusted to the set target pH value=11.8, and the bottom liquid is not stirred by the react...

Embodiment 2

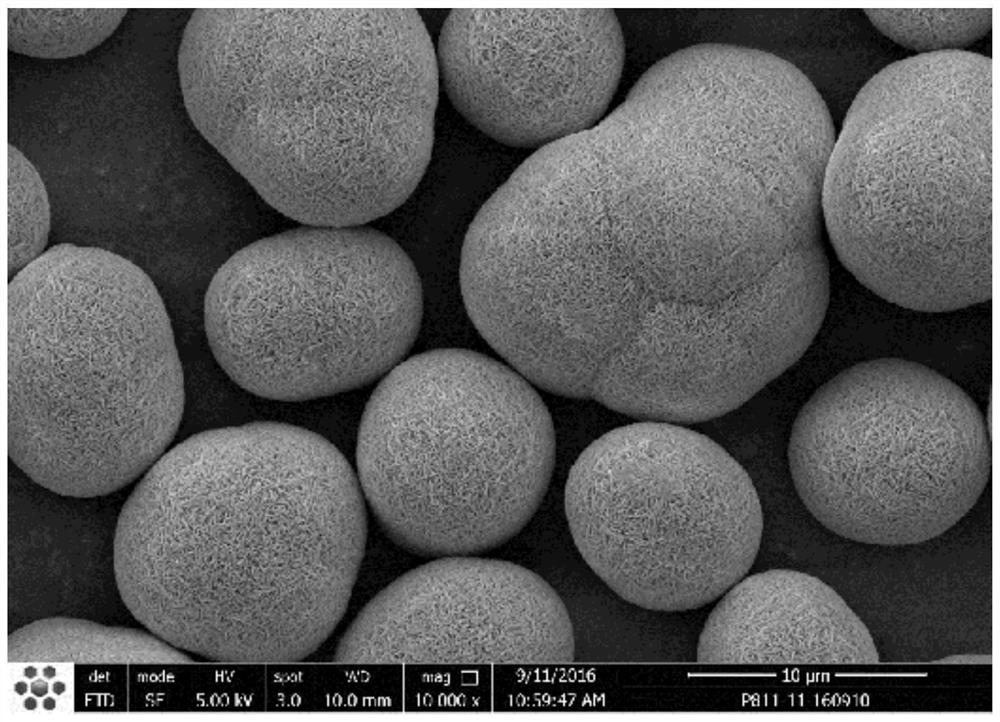

[0085] A kind of nickel-rich precursor material Ni 0.85 Co 0.1 Mn 0.05 (OH) 2 The preparation method of nickel-rich precursor material Ni 0.85 Co 0.1 Mn 0.05 (OH) 2 D 50 The size is set to 10 ± 0.5 μm, and the preparation method specifically includes the following steps:

[0086] (1) According to the molecular formula of Ni-rich precursor material Ni 0.85 Co 0.1 Mn 0.05 (OH) 2 In the ratio of metal ions, the mixed metal salt solution of 2mol / L, the sodium hydroxide solution of 10mol / L and the ammonia water of 13mol / L are prepared;

[0087] (2) pump the ammoniacal liquor of 13mol / L in the reactor, make the ammonia concentration of the liquid at the bottom of the reactor be the set target ammonia concentration 11-12g / L, then use the sodium hydroxide solution of 10mol / L to make the bottom of the reactor The pH of the liquid is adjusted to the set target pH value=11.9, and the bottom liquid is not passed through the stirring paddle of the reactor;

[0088] (3) Charge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com